JeepParts

My Garage

My Account

Cart

OEM 2003 Dodge Sprinter 2500 Fuel Rail

Engine Fuel Rail- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Fuel Rail found

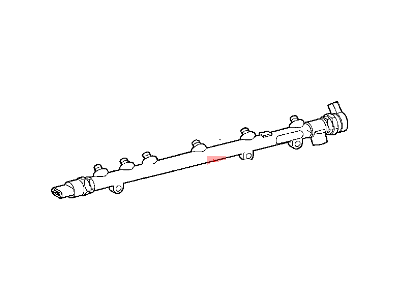

2003 Dodge Sprinter 2500 Fuel Rail Part Number: 5137290AA

Product Specifications- Other Name: Rail - Fuel; Rail Fuel

- Item Weight: 7.90 Pounds

- Item Dimensions: 28.9 x 6.1 x 6.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5137290AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2003 Dodge Sprinter 2500 Fuel Rail Parts and Q&A

- Q: How to Service and Repair a Fuel Rail on 2003 Dodge Sprinter 2500?A: Take the first steps of fuel rail service or repair by removing the negative battery cable and semi-draining the system at the radiator. Takes off the thermostat housing and cut the engine wire connections to the sensor parts to free up space. Next, remove the engine harness bolts and then take the fuel temperature sensor off the fuel rail. Following this, unscrew the fuel rail mounting bolts, take out the spark plug connectors and lift the engine support in front of the motor. Always use two wrenches, holding tight at the ends of the lines as you turn the nuts, so you don't overtighten or bend them. Remove the lines, seal the pipes and make sure to keep everything clean from then on. Set about taking away the injector high-pressure lines, the high-pressure pump pressure line and separating the fuel return line to the pump and filter. To begin installation, loosely put the fuel rail on the cylinder head and tie the fuel return line loosely to the rail from the new filter, sealing it with the other end of the tube. Attach the fuel rail to the head and fill it with the new high-pressure line and examine both seals and cones at the connections, replacing them if defective. Turn on every injector by hand and when torquing the fuel injection line union nuts, hold a wrench against the connection and do not apply more torque than is permitted. Tighten the bolts on the fuel rail to 14 N.m (124 lbs.in.), the pressure line nut on the rail/injector to 22 N.m (194 lbs.in.), the pressure line nut on the pump/rail to 22 N.m (194 lbs.in.) and the fuel return line banjo bolt to the fuel rail to 20 N.m (177 lbs.in.). Secure the installations of the fuel sensor and the front engine lift and then put in the thermostat housing. Replace the engine wiring connectors, add fresh coolant to the system and plug the black negative battery cable into the battery. Be very careful around the fan, with pulleys, belts or while the engine is in use and avoid standing directly in front of the fan with your hands. After that, start the engine and check for any leaks.