JeepParts

My Garage

My Account

Cart

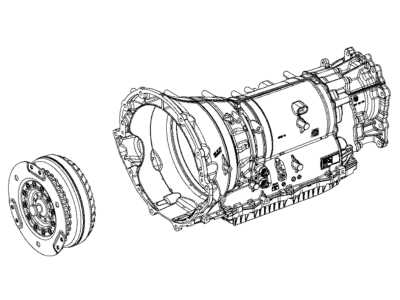

OEM Ram 2500 Torque Converter

Transmission Torque Converter- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Torque Converters found

Ram 2500 Transmission Part Number: 68449198AA

$3252.78 MSRP: $3730.00You Save: $477.22 (13%)Ships in 1-3 Business DaysRam 2500 Transmission Part Number: 68449199AA

$5975.30 MSRP: $7150.00You Save: $1174.70 (17%)

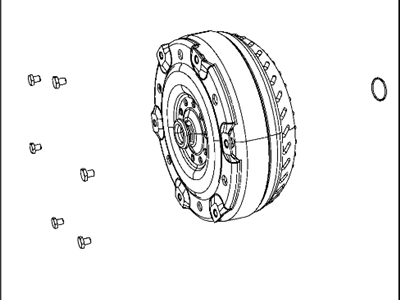

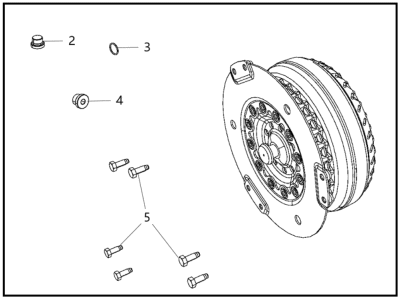

Ram 2500 Torque Converter Part Number: RL109671AH

$373.47 MSRP: $526.00You Save: $152.53 (29%)Ram 2500 Torque Converter Part Number: 68466765AA

$1201.78 MSRP: $1755.00You Save: $553.22 (32%)

Ram 2500 Torque Converter

Choose OEM Torque Converter that meet Ram factory standards. Ram designs and tests every component for precision and durability. Each Torque Converter follows strict manufacturing steps to lock in quality and fit. If your Ram 2500 matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine 2500 parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

Ram 2500 Torque Converter is the core of a heavy duty pickup that is characterized by gutsy pulling force, a comfortable cab and a frame that will shake off bad work sites and as a result, Ram 2500 is a very popular pickup among both the family and the tradesmen. The truck incorporates intelligent suspension adjustment with accurate steering to ensure that day-to-day driving experience is confident and at the same time the trailer is pulled in case of large trailers, at the same time the bed accommodating diversities and accommodating seats assure that power can be accompanied with a long ride feel. The simplicity of service structure and provision of original components also attracts owners to keep the Ram 2500 in the road many years. In this driveline, the Ram 2500 Torque Converter is a type of fluid coupling, which connects engine speed to the automatic gearbox, increases torque at takeoff and also allows the engine to idle smoothly at stoplights, which is characteristic of performance and fuel economy protection. The impeller, turbine and stator are enclosed by a sealed housing and they rotate in unison locking up at cruise to minimize slippage and heat and increase highway efficiency and frequent fluid checks and proper stall speed matching keep Torque Converter wear to a minimum. A healthy Torque Converter in a Ram 2500 can get up steep grades without blinking, when it is kept in good condition. Installation: ensure fit, pour in clean fluid, lubricate the hub, ensure that the unit is completely seated on the splines, align with the flexplate, affix evenly, refill and test drive, making sure that the Torque Converter spins freely.