JeepParts

My Garage

My Account

Cart

OEM Ram Coil Spring Insulator

Coil Spring Noise Insulator- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

23 Coil Spring Insulators found

Ram Spring Insulator, Front Part Number: 5168566AB

$57.03 MSRP: $85.55You Save: $28.52 (34%)Product Specifications- Other Name: Isolator - Spring; Coil Spring Insulator, Front, Front Upper; Upper Insulator; Insulator; Isolator Spring Upper; Coil Spring Insulator

- Position: Front

- Replaces: 5168566AA

Ram Spring Insulator, Upper Part Number: 4721581AA

$28.13 MSRP: $41.95You Save: $13.82 (33%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Isolator - Spring; Coil Spring Insulator, Lower, Upper; Isolator; Isolator Spring; Coil Spring Insulator

- Position: Upper

Ram Lower Spring Insulator Part Number: 68143588AA

$46.23 MSRP: $67.60You Save: $21.37 (32%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Isolator - Spring; Coil Spring Insulator; Isolator Spring

Ram Spring Isolator, Front Part Number: 52037719AC

$44.38 MSRP: $66.15You Save: $21.77 (33%)Product Specifications- Other Name: Isolator - Spring; Coil Spring Insulator, Front Lower; Shock Mount Insulator.; Spring Insulator; Isolator; Isolator Spring Upper

- Position: Front

Ram Spring Insulator, Front Part Number: 68268825AA

$74.38 MSRP: $112.00You Save: $37.62 (34%)Product Specifications- Other Name: Isolator - Spring; Coil Spring Insulator, Front, Front Upper; Upper Insulator; Insulator; Isolator Spring Upper; Coil Spring Insulator

- Position: Front

Ram Spring Insulator, Upper Part Number: 55366387AA

$14.57 MSRP: $17.20You Save: $2.63 (16%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Isolator - Spring; Coil Spring Insulator, Front Upper; Shock Mount Insulator; Upper Insulator; Upper Spring Insulator; Shock Upper Insulator; Isolator; Isolator Spring; Coil Spring Insulator

- Position: Upper

- Replaced by: 55366387AB

Ram Spring Isolator, Upper Part Number: 52106717AA

$24.71 MSRP: $35.60You Save: $10.89 (31%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Isolator - Spring; Coil Spring Insulator, Front, Front Upper, Upper; Coil Insulator; Spring Insulator; Upper Insulator; Coil Spring Insulator.

- Position: Upper

- Replaces: 52037718

Ram Spring Seat, Lower Part Number: 55366975AB

$47.59 MSRP: $61.30You Save: $13.71 (23%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Isolator - Spring Seat; Coil Spring Insulator, Front Lower; Coil Spring Insulator, Lower; Coil Spring Retainer, Front; Spring Insulator; Lower Insulator; Shock Lower Insulator; Isolator; Isolator Spring Seat; Coil Spring Insulator

- Position: Lower

- Replaces: 55366975AA

Ram Spring Insulator, Rear Part Number: 52855789AB

$16.42 MSRP: $24.05You Save: $7.63 (32%)Product Specifications- Other Name: Isolator - Spring; Coil Spring Insulator, Rear; Isolator Spring; Coil Spring Insulator

- Position: Rear

- Replaces: 52855789AA

Ram Lower Insulator, Front Part Number: 68137838AB

$47.08 MSRP: $70.10You Save: $23.02 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Isolator - Spring; Coil Spring Insulator, Front Lower; Isolator Spring Lower; Coil Spring Insulator

- Position: Front Lower

- Replaces: 68137838AA

Ram Spring Insulator Part Number: 4721350AA

$28.03 MSRP: $41.45You Save: $13.42 (33%)Product Specifications- Other Name: Isolator - Spring Seat; Coil Spring Insulator; Spring Lower Insulator; Isolator Spring Seat

Ram Spring Insulator, Front Part Number: 68210979AA

$13.11 MSRP: $19.30You Save: $6.19 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Isolator - Spring; Coil Spring Insulator, Front, Front Left, Front Lower, Lower, Rear Upper; Spring Seat; Lower Insulator; Lower Seat; Insulator; Isolator; Isolator Spring; Coil Spring Insulator

- Position: Front

- Replaces: 5085405AA, 5085405AB, 5085405AC

Ram Spring Insulator, Rear Part Number: 68273964AB

$11.17 MSRP: $16.35You Save: $5.18 (32%)Product Specifications- Other Name: Isolator - Spring; Coil Spring Insulator, Rear; Isolator Spring; Coil Spring Insulator

- Position: Rear

- Replaces: 68273964AA

Ram Isolator - Spring Seat Part Number: 68365922AB

$5.63 MSRP: $8.10You Save: $2.47 (31%)Ships in 1-2 Business DaysProduct Specifications- Other Name: ISOLATOR-SPRING SEAT

Ram Isolator - Spring Part Number: 68507517AB

$25.76 MSRP: $37.75You Save: $11.99 (32%)Ships in 1-2 Business DaysProduct Specifications- Other Name: ISOLATOR-SPRING

- Replaces: 68507517AA

Ram Spring Isolator, Rear Part Number: 68143589AC

$58.98 MSRP: $88.25You Save: $29.27 (34%)Product Specifications- Other Name: Isolator - Spring; Coil Spring Insulator, Rear; Spring Insulator; Upper Spring Insulator; Isolator Spring; Coil Spring Insulator

- Position: Rear

- Replaces: 68143589AB, 68143589AA

Ram Lower Spring Insulator, Rear Driver Side Part Number: 68263303AA

$11.18 MSRP: $16.60You Save: $5.42 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Isolator - Rear Suspension Spring; Coil Spring Insulator, Rear Left Lower; Lower Seat; Isolator Rear Suspension Spring; Coil Spring Insulator

- Position: Rear Lower Driver Side

Ram Isolator - Spring Part Number: 68507516AB

$26.51 MSRP: $38.15You Save: $11.64 (31%)Product Specifications- Other Name: ISOLATOR-SPRING

- Replaces: 68507516AA

Ram Spring Insulator, Upper Part Number: 68051297AA

Product Specifications- Other Name: Isolator - Spring; Coil Spring Insulator, Upper; Upper Insulator; Isolator Spring Upper; Coil Spring Insulator

- Position: Upper

Ram Spring Insulator Part Number: 68443389AB

$49.30 MSRP: $71.15You Save: $21.85 (31%)Product Specifications- Other Name: Isolator - Spring; Coil Spring Insulator

| Page 1 of 2 |Next >

1-20 of 23 Results

Ram Coil Spring Insulator

OEM parts sourced directly from Ram deliver superior quality, long lasting strength, and a precise fit you can trust. Each item goes through strict quality checks to ensure safety, toughness, and performance that matches your factory equipment. At JeepPartsDeal online shop, you'll get top-quality, budget-friendly OEM Ram Coil Spring Insulator for your vehicle. We focus on giving you a high standard without pushing up the price. Our full selection of genuine factory products comes backed by the original manufacturer's warranty. You'll love our fast delivery, seamless shopping experience, and convenient return policy, saving you all the hassle.

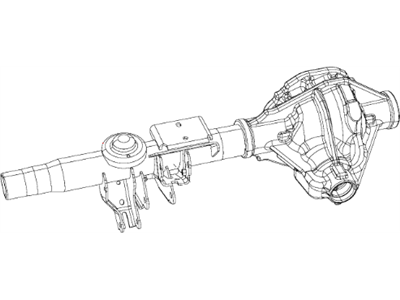

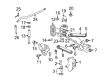

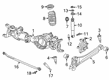

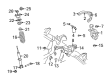

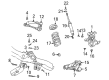

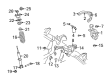

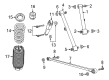

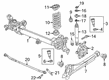

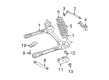

The Ram Coil Spring Insulator is installed between the coil of the truck and seat absorbing the vibration and preventing contact between the metal to ensure the suspension remains silent and intact. The Ram trucks belong to years of pickup tradition, and the current Ram vehicles stretch comfort and brains beyond competitors with cushy silent cabins, huge touch screens, and ingenious RamBox which stores equipment safely without touching the side of the bed. An air suspension raises two and eight inches to be able to tackle rocky trails and an e-Torque mild hybrid system adds smooth low-speed muscle along with better mileage. This combination of power, technology and everyday usefulness reveals why Ram pickups continue to find new converts who pull, push and drive around on a daily basis. Then when the Coil Spring Insulator requires replacement, it is not difficult. Park in flat terrain, chock the wheels, lift the frame of Ram with a jack, and place heavy stands under the chassis. Loosen the wheel and lift the control arm or axle and squeeze the spring with a compressor of rated strength. To clean the seat, slide out the spring, remove the Coil Spring Insulator that is worn out and scrub the seat. Install the new Coil Spring Insulator in the correct position, and re-install the spring maintaining the end of the spring in the same position in its pocket, and then gradually release the compressor until the assembly fits into position. Reconnect the hardware, tighten the bolts to standards, re-fit the wheel, lower the truck, and make a test run to make sure the fix is working.