JeepParts

My Garage

My Account

Cart

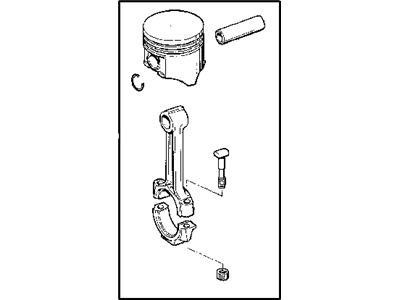

OEM 2000 Chrysler LHS Piston

Engine Pistons- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Piston found

2000 Chrysler LHS Piston Part Number: R5010335AB

Product Specifications- Other Name: Piston Pin And Rod

- Replaces: 5010335AB

- Item Weight: 3.10 Pounds

- Item Dimensions: 12.9 x 5.8 x 4.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: R5010335AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2000 Chrysler LHS Piston Parts and Q&A

- Q: How to Remove and Replace a Piston in an Engine on 2000 Chrysler LHS?A: Before putting in a new piston, take off the cylinder heads and oil pan first. Make sure to use a good ridge reamer to smooth out the ridge on top of the cylinder, covering the tops of the pistons during this process. You should remove the pistons and connecting rods from the top of the cylinder block, then turn the crankshaft to center every connecting rod in its bore. Check the connecting rods and caps to identify the cylinders and add markings when required. Take off the cap on the connecting rod and set up protector bearings on all the connecting rod bolts before carefully working each piston and rod assembly out of the cylinder bore, avoiding the crankshaft journals. Mount the bearing cap on the surface of the mating rod after removal. You should install the No. 2 piston ring so that the manufacturer's identification mark faces the top of the cylinder. The order of installing the piston rings is oil ring expander, upper oil ring side rail, lower oil ring side rail, No. 2 intermediate piston ring, and No. 1 upper piston ring. Place one side rail between the piston ring groove and the expander, then push down firmly so that it is in the right position without an expander. First, place the upper side rail, then the lower side rail, and afterward the No. 2 and No. 1 piston rings, adjusting their end gaps properly. The oil ring expander gap should be at least 45° from the side rail gaps. Check if the connecting rod bearing cap bolts have necked before setting the pistons and connecting rod assemblies in place. Make sure the gaps between the compression and oil rings are not side by side with the oil ring rail gap. Be sure that the ends of the oil ring expander are joined without any spaces and that the rail gaps are put into position before using the ring compressor. Dip the piston's head and rings in some clean oil, fit the ring compressor on the piston, and tightly screw it in place using the proper wrench, so the location of the rings stays unchanged. Add bolt protectors to the connecting rods, turn the crankshaft to get the rod journal straight in the bore, and move the piston and connecting rod into the cylinder. The piston's arrow should be located in front of the engine and the oil squirt hole should be aimed at the largest force side of the cylinder bore. Press the piston into the cylinder bore using a hammer handle as you make sure the connecting rod is in position on the journal. After that, put on the rod caps, tighten the nuts onto the cleaned and oiled rod bolts to 54 Nm (40 ft. lbs.) plus a 1/4 turn and place the cylinder heads and oil pan back into place.