JeepParts

My Garage

My Account

Cart

OEM 2000 Dodge Intrepid Brake Caliper

Caliper- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Brake Calipers found

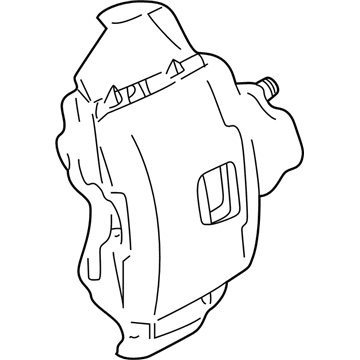

- Product Specifications

- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Rear Right; Brake Caliper; Caliper

- Position: Rear Passenger Side

- Item Weight: 4.40 Pounds

- Item Dimensions: 8.9 x 6.5 x 5.7 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5011746AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

- Product Specifications

- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Rear Left; Brake Caliper; Caliper

- Position: Rear Driver Side

- Item Weight: 4.10 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5011747AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

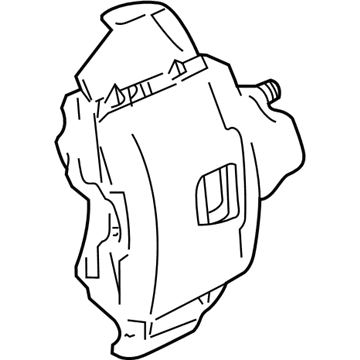

- Product Specifications

- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Front Right; Caliper; Caliper Disc Brake; Brake Caliper

- Position: Front Passenger Side

- Item Weight: 7.70 Pounds

- Item Dimensions: 8.7 x 7.1 x 5.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5010032AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

- Product Specifications

- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Front Left; Caliper; Caliper Disc Brake; Brake Caliper

- Position: Front Driver Side

- Item Weight: 7.80 Pounds

- Item Dimensions: 8.3 x 6.7 x 5.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5010033AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2000 Dodge Intrepid Brake Caliper Parts and Q&A

- Q: How to Effectively Service and Repair a Brake Caliper on 2000 Dodge Intrepid?A: The first step to services and repairs for calipers is to look for leaks in brake fluid around the dust boot and the inboard brake pad; also, check for any damage to the piston dust boot. Should the dust boot be damaged or a leak happen, you'll need to take apart the caliper and install a new seal, dust boot and piston if they are required. Check that the guide pin dust boots are not torn or crumbly and change them if that's the case. For working on the caliper's bushing, hang the caliper from a wire hook while it is off the rotor. Grasp the top of the steel sleeve and push it out of the bushing, then flatten one end and pull the other to slide the whole bushing out of its housing. To install, lay the bushing flat and fold it so it's skinny, then guide it into the caliper without using any sharp devices. Open the bushing into position until the flanges on either side appear level. Coat the internal surfaces of the bushing with Mopar, Silicone Dielectric Compound or an alternative and press the guide pin sleeve into one end until the seal area just clears the seal groove. Slide the steel sleeve into the boot through the bottom end and press the other end of the bushing over the sleeve right into the seal groove. Hold the sleeve in place and make sure it moves smoothly and doesn't pop on either end. Put friction bolts aside, hang the caliper after removing it from the rotor to prevent hydraulic fluid from touching the rotor during disassembly. Put a bit of wood between the brake caliper finger and piston and depress the brake pedal. Keep the pedal down to stop any brake fluid from escaping. If you have to take out both front caliper pistons, unplug the brake tube from the soft flex hose and clip it up before removing the piston from the opposite caliper. When disconnecting the brake fluid flex hose, clamp the caliper in a vise, but don't squeeze too strongly so as not to wrinkle the bore inside. Fix the caliper in a vise with soft jaws, pull out the guide pin sleeves and bushings and throw away the piston dust boot. Remove the old piston seal by using a soft tool and then discard it, clean the housing, piston and complete the bore with alcohol or a similar liquid, dusting with a lint-free cloth. With crocus cloth, check for light scratches and use a Caliper Hone, Special Tool C-4095, to clean the bore when needed, so that it doesn't measure more than 0.001 inch. If the bore is not cleaned properly, the caliper housing must be replaced and a damaged piston should be changed as well. Pour brake fluid on the stones and bores and clean the grooves in the seal and boot with a solid rotary brush. Check the piston in the caliper for damage and exchange it with a new one if required. To assemble the system, use protective caps, dip a new piston seal in brake cleaner fluid and place it into the bore of the caliper before securing the whole unit in a vise. Add brake fluid to the new piston boot, place it on the piston and evenly press it down to keep it from binding. Push the piston all the way into the caliper bore, then place the dust boot in the counterbore and use Installer Piston Caliper Boot, Special Tool C-4689 and Handle, Special Tool C-4171to press it into place. Place the guide pin sleeves and bushings and afterwards set the brake pads. Before you fit the caliper, look at the brake rotor for symptoms that call for a replacement or refacing. Should the rotor be in good shape, place the caliper assembly, hook up the brake hose with a banjo bolt and apply each side to 33 Nm (24 ft. lbs.) using new seal washers. Bleed the brake system in the end.