JeepParts

My Garage

My Account

Cart

OEM Dodge Intrepid Brake Caliper

Caliper- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Brake Calipers found

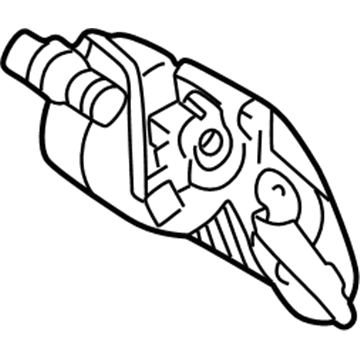

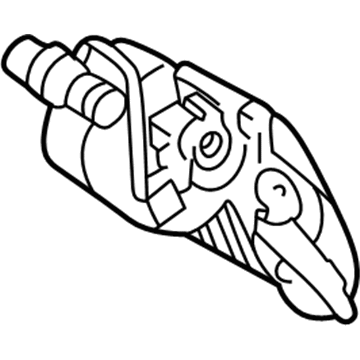

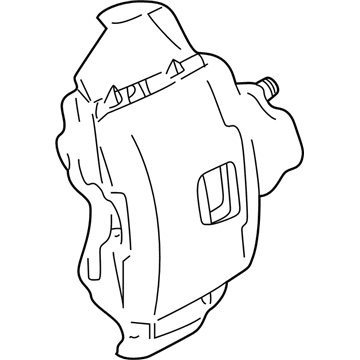

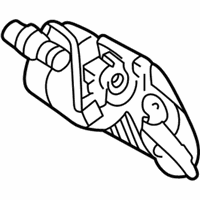

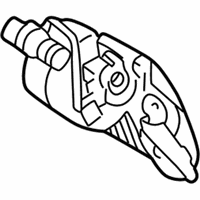

Dodge Intrepid Caliper Assembly Part Number: 5011701AA

Dodge Intrepid Caliper Assembly Part Number: 5011700AA

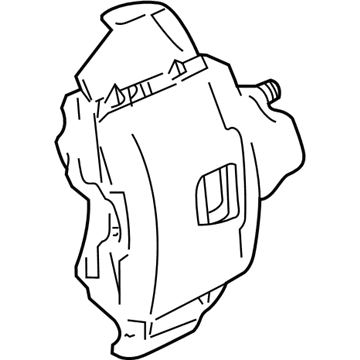

Dodge Intrepid Brake Caliper

Choose OEM Brake Caliper that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Brake Caliper follows strict manufacturing steps to lock in quality and fit. If your Dodge Intrepid matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Intrepid parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

The Dodge Intrepid Brake Caliper establishes itself as a vital element which delivers reliable braking service within Dodge Intrepid vehicles. The necessary mechanism within brakes uses master cylinder pressure to apply mechanical pad pressure onto rotors thus helping vehicles achieve slowing or stopping movements. The braking system of Dodge Intrepid models contains fixed brake calipers together with floating brake calipers that deliver steady pressure from multiple pistons leading to superior performance. Dodge Brake Calipers keep their lifespan extended by using cast iron bodies together with steel or phenolic pistons in their construction. The Dodge Intrepid Brake Caliper requires periodic inspections to stop problems from developing including vehicle pulling problems and brake fluid leaks and pad wear imbalances that decrease safety measures. The Dodge Intrepid Brake Caliper elevates both the safety and efficiency of the vehicle thus standing out as a primary advantage in automotive production. Various Intrepid versions consisting of Base, ES and R/T trims support this caliper's function therefore providing universal performance benefit. The the automaker model Brake Caliper maintains a focus on safety since it cooperates perfectly with vehicle systems including four-wheel disc brakes and anti-lock braking which make it an excellent option for drivers who require both performance capability and protection on the streets.

Dodge Intrepid Brake Caliper Parts and Q&A

- Q: How to Assess and Repair Rear Disc Brake Caliper Lining Wear on Dodge Intrepid?A:The rear brake caliper lining can be inspected by first removing both the wheel and tire from the car, next remove the rear brake caliper and lastly the rear brake lining. If the brake shoe and lining at the thin end add up to about 7.0 mm (9/32 inch), change out both sets of brake shoes and make sure you change both rear wheels as well. Do not dismantle the brakes further unless it is necessary to replace an assembly. During caliper inspection, check for leaks from the brake fluid around the caliper's boot and inboard lining and also check the Piston dust boot for any ruptures, cracks or damage. With a damaged boot or leak, part the caliper and set up a new seal, boot and piston if it shows signs of scoring. Examine the dust boots on each guide pin too and change them if they are torn, appear dry or if they feel brittle.

- Q: How to Safely Service a Rear Disc Brake Caliper to Prevent Asbestos Exposure on Dodge Intrepid?A:Ensure you use care while changing a rear disc brake caliper since asbestos may be hidden in the dirt and dust on the parts. Never grind or sand brake linings unless using dust-trapping equipment and you should not clean brake parts with compressed air or by dry brushing them. Rather, lightly wet your brake assembly with water and use a damp cloth to wipe it, putting the cloth and anything else wet in a proper container that won't leak. Handle and remove asbestos material based on the regulations from OSHA and EPA. To flush or clean the brake caliper's inner channels, apply fresh brake fluid or Mopar(R) Non-Chlorinated Brake Parts Cleaner, since gasoline, kerosene, alcohol, oil, transmission fluid or any mineral oil-containing fluid might damage the rubber seals and cups. While checking the caliper, look for brake fluid leaks close to the rubber boot and at the inner part and make sure the piston boot and guide pin boots are not torn, dried or brittle. Should the caliper not pass inspection, remove all parts, clean them and install replacements for any worn out seals or dust boots needed.