JeepParts

My Garage

My Account

Cart

OEM 2002 Dodge Ram 3500 Universal Joint

U-Joint- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Universal Joints found

2002 Dodge Ram 3500 Axle Shaft, Front Part Number: 5003004AB

$91.84 MSRP: $204.00You Save: $112.16 (55%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Universal Joint - Front Axle; U Joint; Universal Joints; U-Joint; U Joint Front Axle; Universal Joint

- Position: Front

- Item Weight: 2.60 Pounds

- Item Dimensions: 4.2 x 5.3 x 1.7 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5003004AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

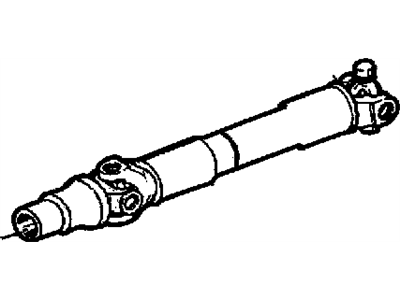

2002 Dodge Ram 3500 Universal Joints Part Number: 5014733AB

$59.52 MSRP: $130.00You Save: $70.48 (55%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Joint; Universal Joint; CV Joint; U Joint; Rear Universal Joint; U-Joint; Universal Joint Kit

- Replaces: 5014062AA, 5014733AA

- Item Weight: 1.70 Pounds

- Item Dimensions: 1.4 x 6.2 x 7.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5014733AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2002 Dodge Ram 3500 Universal Joints Part Number: 68127993AA

$87.29 MSRP: $194.00You Save: $106.71 (56%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Joint; Universal Joint; CV Joint; U Joint; U-Joint

- Replaces: 5102060AA, 5142892AA, 5003146AA, 5142891AA

- Item Weight: 2.30 Pounds

- Item Dimensions: 0.2 x 3.9 x 4.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 68127993AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2002 Dodge Ram 3500 Universal Joint Parts and Q&A

- Q: How to Maintain and Repair Universal Joints in a Double Cardan System on 2002 Dodge Ram 3500?A: When servicing double Cardan joints, first remove the shaft and mark the link and flange yokes so you can put the parts back properly. Rap the outside of the bearing cap assembly with a drift to loosen and remove the snap rings from the bearings. Should the engine be fitted with grease fittings, detach them now. Having fitted halfway through the yoke, start the bearing cap by placing a socket with a larger internal size beneath. Put a socket with a less wide internal diameter on the top part of the bearing cap. On the outboard side of the link yoke, push out the bearing cap just enough to grasp with the vise and now hit the link yoke with a mallet and drift to remove it. Once again, overturn the device and press and tap to unscrew the other bearing cap. Moving the link yoke's cross centering kit assembly and spring aside, remove the rest of the bearing caps from the other side. For successful assembly, line up all the alignment marks found on the link yoke and propeller shaft yoke. Put some Extreme Pressure N.L.G.I. Grade 1 or 2 grease around the inside of the yoke bores, fit the cross into the propeller shaft yoke and position a bearing cap on the trunnion. Pushing the bearing cap in the yoke to go over the ring groove allows you to install the ring. Turn the propeller shaft yoke, fit the cap onto the other trunnion and set a snap ring in place. Install the link yoke onto the last trunnions, put the bearing caps into their places and install the snap rings. Install the kit inside the link yoke, checking to see that the spring is set correctly. Set two bearing caps on the cross ends away from you, slip in the open trunnions to the yokes and align the bearing caps within the centering kit. Place the last two bearing caps onto the device and slide the snap rings into the grooves, giving them a good tap to seat. Inspect the entire joint and take it beyond halfway and it should easily snap back over into either side; if this occurs properly, insert the propeller shaft to install it.