JeepParts

My Garage

My Account

Cart

OEM 2003 Dodge Neon Intake Manifold

Engine Intake Manifold- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Intake Manifolds found

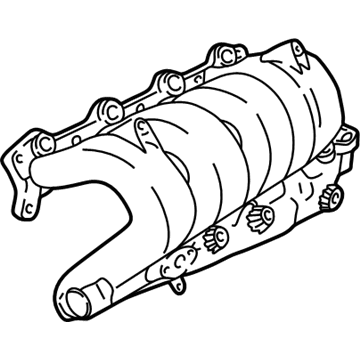

2003 Dodge Neon Intake Manifold Part Number: 4777379

Product Specifications- Other Name: Manifold - Intake; Engine Intake Manifold; Manifold Intake

- Item Weight: 5.70 Pounds

- Item Dimensions: 17.9 x 15.6 x 10.9 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4777379

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

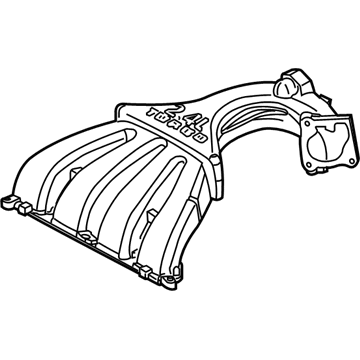

2003 Dodge Neon Intake Manifold Part Number: 5045002AA

Product Specifications- Other Name: Manifold - Intake; Engine Intake Manifold; Manifold Intake

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5045002AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2003 Dodge Neon Intake Manifold Part Number: 5018787AC

Product Specifications- Other Name: Manifold - Intake; Engine Intake Manifold; Manifold Intake

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5018787AC

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2003 Dodge Neon Intake Manifold Part Number: 4884065AE

Product Specifications- Other Name: Manifold - Intake; Engine Intake Manifold; Manifold Intake

- Item Weight: 10.60 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4884065AE

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2003 Dodge Neon Intake Manifold Parts and Q&A

- Q: How to Service an Intake Manifold on 2003 Dodge Neon?A: Before starting to service the intake manifold, relieve the fuel system pressure and ventilate the area, as well as keep it safe from You should do the same to prevent ignition and smoking. First, remove the negative battery cable and after that, pull the inlet air duct away from the throttle body. Move the shop towel around the hose and hook it inside to prevent muddy water from spilling when you undo the quick connect at the fuel tube assembly. Unscrew the attaching screws on the fuel rail and close the holes inside to stop contamination, always ensuring you are not placing the fuel injectors on their tips. Remove the brake booster hose and PCV line from the intake manifold, plus the connectors for the Manifold Absolute Pressure (MAP) sensor and knock sensor. Disjoin the wiring at the starter, then unbolt the bracket and groundstops holding the intake manifold to remove it, taking off the manifold screws and washers as you discard them. Check the manifold for cracks, dents or distortions and verify that there are no torn or missing O-rings at the contacting surface. Clean both sides of the component before installation and set new O-ring gaskets, washers and fasteners. Attach the intake manifold to the cylinder head and tighten all fasteners to 12 Nm (105 in. lbs.), then complete with the lower support bracket bolts at 11 Nm (95 in. lbs.). Lift off the cover from the fuel injector holes, checking they are clean and set the fuel rail in place, securing the screws at 23 Nm (200 in. lbs.). Reinstall the PCV and brake booster hoses, examine the quick connect fittings, put a small amount of clean engine oil on the fuel inlet tube and attach the fuel supply hose to the fuel rail assembly, verified that it locks into place. Connect again the MAP sensor's wiring, the knock sensor's connection and the wiring at the starter. Secure the inlet air duct to the intake manifold and throttle body using a clamp tightened to 3 Nm (30 in. lbs.) and then put the negative battery cable back. Finally, run the DRB scan tool's ASD Fuel System Test to create pressure within the system and detect any leaks, making sure the Auto Shutdown relay stays live for 7 full minutes or until the time period ends or you turn off and restart the engine by first engaging the Stop All Test.