JeepParts

My Garage

My Account

Cart

OEM 2004 Dodge Caravan Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Crankshafts found

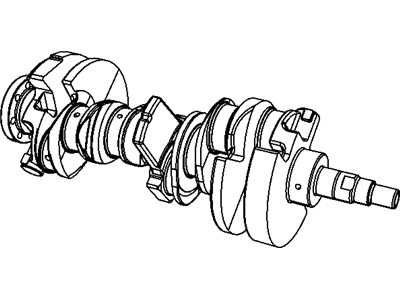

2004 Dodge Caravan Crankshaft Part Number: 4621983AD

$299.79 MSRP: $1045.00You Save: $745.21 (72%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Crankshft

- Replaces: 4621983AB

- Item Weight: 47.30 Pounds

- Item Dimensions: 25.8 x 8.2 x 8.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4621983AD

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

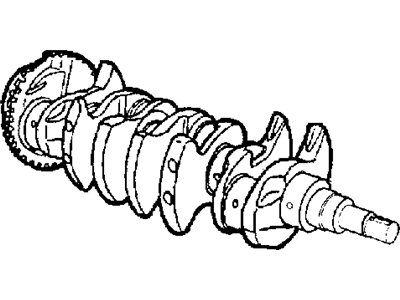

2004 Dodge Caravan Crankshaft Part Number: 4781643AA

$539.13 MSRP: $818.00You Save: $278.87 (35%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Crankshft; Crankshaft Includes Target Ring And Screw

- Item Weight: 47.80 Pounds

- Item Dimensions: 24.5 x 8.8 x 8.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4781643AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2004 Dodge Caravan Crankshaft Parts and Q&A

- Q: How to Remove and Install a Crankshaft in an Engine Assembly on 2004 Dodge Caravan?A: You must pull out the engine assembly, detach the transaxle from the engine and after that remove the drive plate/flex plate to get the crankshaft out. The rear oil seal on the crankshaft should be removed and the engine should be mounted on a repair stand. Before you start, drain the oil, change the filter, remove the damper and remove the engine mount support bracket as well. Then, get rid of the front and rear timing belt covers, the timing belt and the oil pan and afterwards disconnect the oil pump pick-up tube. The crankshaft sprocket, oil pump, balance shaft assembly and housing should be taken out too, as well as the crankshaft position sensor. For piston or connecting rod replacement, it is necessary to take out the cylinder head. Use a paint or ink marker to write each cap's label on the connecting rods, rather than putting a mark there with a number stamp or punch. Make sure not to damage the fracture rod and cap surfaces as you take out all connecting rod bolts and caps and do not try to use the old connecting rod bolts again. Take all the bed plate bolts out of the engine block and carefully blow the bed plate out to the dowels without forcing anything. Make sure to lift the crankshaft away from the engine, without harming the main bearings or journals and then remove the mounting screws holding the target ring before releasing it. While inspecting, make sure the crankshaft journals are not too worn, are not showing any taper or scored marks and that the limits of taper, out of round and grinding are each smaller than 0.025 mm (0.001 inch). Align the main bearing upper shells on the crankshaft with their lubrication grooves when you set it in place and clean the crankshaft and target ring with a spray of Mopar6 brake parts cleaner. Replace the mounting screws for the target ring, set them to 13 Nm (110 inch lbs.) and before putting on the crankshaft, lubricate all bearings and journal parts. Place low-hour main bearings into the bearing cap or bottom plate, making sure they're seated properly and use Mopar Bed Plate Sealant around the base of the engine. Put the main bearing or bed plate in the engine, lubricate the bolt threads and turn them tightly until the bed plate touches the cylinder block. Spin the crankshaft to make sure the thrust bearing is aligned, then put in the bolts in order and tighten them to 41 Nm (30 ft. lbs.), then turn them one more quarter turn. Loosen the remaining main bearing bed plate bolts and rotate the crankshaft until it's 90 degrees; then, tighten the bolts to 28 Nm (250 inch lbs.), still checking the crankshaft turning torque so it remains under 5.6 Nm (50 inch lbs.) and check if there is end play. The connecting rod bearings and caps are installed next, connected rod bolts are tightened to 27 Nm (20 ft. lbs.) plus another 1/4 turn, then the balance shafts and housing assembly, the oil pump and the oil pump pick-up tube which has its fastener tightened to 28 Nm (20 ft. lbs.). Following this, install the oil pan, crankshaft position sensor and cylinder head if removed, then the timing belt rear cover, crankshaft sprocket, timing belt and timing belt front covers. Once all is ready, fit the engine mount support bracket, replace the oil filter, put in the crankshaft rear oil seal, install the flex plate and dab Lock & Seal Adhesive along the bolt threads. Then, tighten each bolt to 95 Nm (70 ft. lbs.) for the support bracket, 70 ft. lbs. for the new filter, 128 ft. lbs. for the rear oil seal and 109 ft. lbs. for the flex plate.