JeepParts

My Garage

My Account

Cart

OEM 2005 Dodge Sprinter 2500 Oil Pan

Oil Drain Pan- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Oil Pans found

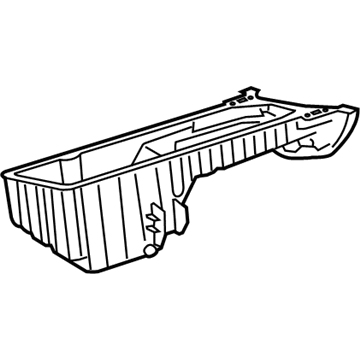

2005 Dodge Sprinter 2500 Oil Pan Part Number: 5117152AA

Product Specifications- Other Name: Pan - Oil; Engine Oil Pan; Pan Oil

- Item Weight: 12.80 Pounds

- Item Dimensions: 25.8 x 13.7 x 8.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5117152AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

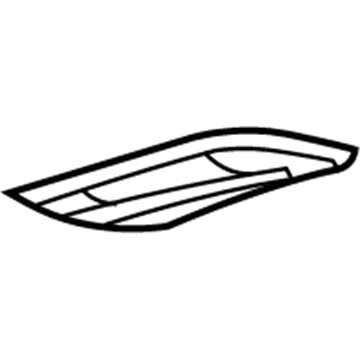

2005 Dodge Sprinter 2500 Tray Part Number: 5117250AA

Product Specifications- Other Name: Pan - Oil; Engine Oil Sump Windage Tray; Pan Oil

- Item Weight: 0.70 Pounds

- Item Dimensions: 1.1 x 1.0 x 1.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5117250AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2005 Dodge Sprinter 2500 Oil Pan Parts and Q&A

- Q: How to Service and Repair an Oil Pan on 2005 Dodge Sprinter 2500?A: Before working on the oil pan, drain the engine's oil first. Swing the sway bar clearing the position where the retaining bolts connect. Disconnect the wiring harness duct from the bolts on the oil pan and put it off to the side. Drop the car and take the upper heat shield off of the turbocharger. Raise the engine slightly by attaching adaptor #853416 to engine support fixture #8534 and attaching the adaptor to the engine lifting eye. Take away the engine mounts and make sure the engine is as high as possible. Pull the oil level sensor out and then loosen and remove the transmission cooler lines attached to the oil pan bolts, making sure the lines aren't touching anything. After removing the oil pan bolts, pull off the oil pan and its gasket. When installing, make sure the oil pan bolts are placed back into their correct spots, because their sizes differ. Clean the oil pump strainer and lubricate its inside with clean engine oil if it is not oily. Wash all mating surfaces carefully with suitable solvents to remove all grease and oil. Slide the oil pan and gasket onto their places and apply sealant to the engine block's joints where directed. Set up the oil pan, screwing in the M6 and M8 bolts with 9 Nm (80 inch lbs.) and 20 Nm (15 ft. lbs.) torque, respectively and lock the bell housing bolt to the oil pan with 40 Nm (30 ft. lbs). After that, secure the wiring harness duct and link the oil level sensor back up. Once the engine and engine supports are both in contact after lowering the suspension, start the engine and hand tighten its mount bolts. Open the engine all the way, then unscrew the engine support fixture and attach the engine to the car using the engine mount bolts tightened to 83 Nm (61 ft. lbs.). Fasten the sway bar and secure all the bolts at a tightness of 30 Nm (22 ft. lbs.), top off the engine oil in the crankcase to the correct mark and attach the cable of the negative battery. When the engine is running, watch out for pulleys and belts, as well as the fan and don't wear anything that might hang loose. Check for signs of leaks after you have safely started the engine.