JeepParts

My Garage

My Account

Cart

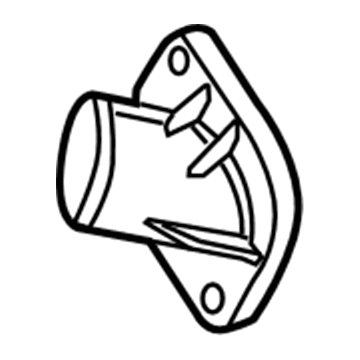

OEM Dodge Dakota Thermostat Housing

Engine Coolant Thermostat Housing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Thermostat Housings found

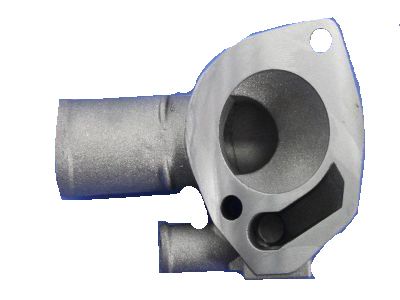

Dodge Dakota Thermostat Housing Part Number: 53020115

$19.08 MSRP: $27.60You Save: $8.52 (31%)

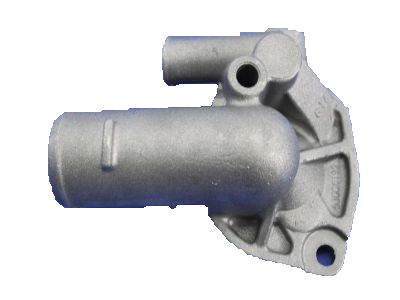

Dodge Dakota Thermostat Housing Part Number: 53006192

$69.07 MSRP: $104.00You Save: $34.93 (34%)

Dodge Dakota Thermostat Housing Part Number: 53020887AD

$9.08 MSRP: $13.35You Save: $4.27 (32%)Ships in 1-2 Business Days

Dodge Dakota Thermostat Housing

Choose OEM Thermostat Housing that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Thermostat Housing follows strict manufacturing steps to lock in quality and fit. If your Dodge Dakota matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Dakota parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

The Dodge Dakota Thermostat Housing is one of the parts which are great regarding its quality and which is of excellent importance with reference to the control of engine temperature. This Thermostat Housing is manufactured to fit a range of Dodge Dakota models and keeps the engine running smoothly to avoid overheating it and thus improving safety. Molded from quality material; metal and high grade plastic; the Dodge Dakota Thermostat Housing is designed to accommodate impacts from the environment as it locks the thermostat firmly in place. Some of the convenient features as gasket or O-ring sealed necks as well as swivel water necks secure seal that does not leak; the opportunity to change position of a hose due to its connection to swivel water necks makes the cooler appropriate for various cooling. The Dodge Dakota Thermostat Housing plays a great role in the durability of the engine as well as the efficiency in performance occasioned by the necessity for proper cooling of the engine bay during intense usage. This component is compatible with a number of Dakota models and should therefore be suitable for many Dodge-car owners. This is where the Dodge Dakota Thermostat Housing comes in: more than just a part that has a specific function, it is also a way to prove that the brand puts its effort to provide only the best. The Dodge Dakota Thermostat Housing is one of the best designed and most durable products in automotive market, which guarantees that car users are able to use their vehicles for all sorts of purposes - be it ordinary, routine driving or more complicated and challenging tasks. In conclusion, this Thermostat Housing is something that everyone need to equip their Dodge Dakota to ensure that it runs safe for further use.

Dodge Dakota Thermostat Housing Parts and Q&A

- Q: How to Service and Repair a Thermostat Housing on Dodge Dakota?A:Begin the thermostat housing service and repair by draining part of the coolant from the radiator into a container, making sure you do not discard unused coolant. For constant tension hose clamps use the special clamp tool (number 6094) and the Snap-On clamp tool (number HPC-20) when the clamps are large and ensure you are wearing safety glasses. When you must use a new constant tension clamp, be sure it is identical to the one that was used before and has the same letter or number that originally appeared on it. If your vehicle lacks air conditioning, get rid of both bypass hose clamps, set the hose in the center and free the hose. When the vehicle has air conditioning, separate the negative terminal from the battery, partially drain the cooling system, unclip the upper radiator hose clamp, remove the hose plus wiring connector from the A/C compressor, take off the air cleaner assembly and lastly remove the accessory Drive Belt. One of the A/C compressor/generator bracket mounting bolts can only be accessed after the drive belt idler pulley is removed. Once you take out the oil dipstick tube mounting bolt, unhook the throttle body cables, remove the hose clamp and hose and then remove the heater hose coolant return tube, discarding its old O-ring. After that, get rid of the bypass hose support plate using the highlighted hex wrench, take out the bracket-to-intake manifold bolts and six bracket bolts and lift the generator and A/C compressor assembly up to expose the bypass hose-use a block of wood to keep the supported assembly off the ground. Place and adjust both clamps over the center area of the bypass hose and then remove it. For installation, put the bypass hose clamps at the hose's center point, install the bypass hose onto the engine and secure both the clamps. Refill the cooling system, start the engine and see if it is leaking. Once you have installed the bypass hose on a vehicle with air conditioning, add the generator-A/C mounting bracket assembly in position and tighten bolts (number 1 and 2) to 54 Nm (40 ft. lbs.); tighten the third bolt to 40 Nm (30 ft. lbs.). Put on a different O-ring to the heater hose coolant return tube, coat it with antifreeze and then attach the tube and its securing bolt to the engine. Rearrange the control wiring for the throttle body, set the oil dipstick mounting bolt and the idler pulley and tighten both fasteners to 54 Nm (40 ft. lbs.). Hold on to the drive belt while you insert it so it doesn't slip, then add the air cleaner assembly, connect the top radiator hose to the radiator, plug the wiring into the A/C compressor and finally reconnect the battery negative wire. After that, complete filling the coolant, ignite the engine, let it warm up and check for flow leaks.