JeepParts

My Garage

My Account

Cart

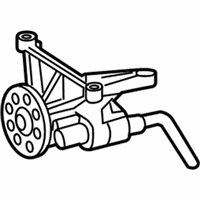

OEM Dodge Sprinter 2500 Oil Pump

Oil Fluid Pump- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Oil Pumps found

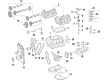

Dodge Sprinter 2500 Oil Pump Part Number: 5179493AA

$566.73 MSRP: $719.00You Save: $152.27 (22%)Ships in 1-2 Business DaysDodge Sprinter 2500 Oil Pump Part Number: 68040893AA

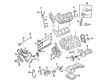

Dodge Sprinter 2500 Oil Pump Part Number: 5117594AA

Dodge Sprinter 2500 Oil Pump

Choose OEM Oil Pump that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Oil Pump follows strict manufacturing steps to lock in quality and fit. If your Dodge Sprinter 2500 matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Sprinter 2500 parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

The Dodge Sprinter 2500 Oil Pump is one of these parts widely appreciated for its efficiency and sturdiness, guaranteeing proper work of the engine in countless Sprinter 2500 vehicles. This Oil Pump is applied to force circulation of oil at a high pressure for purposes of providing lubrication and cooling of critical engine parts like bearings and pistons apart from acting as the hydraulic fluid for minor actuators. The types of oil pumps of the Dodge Sprinter 2500 are different, but mechanical ones are traditional because of their effectiveness. Clogs may also be experienced as a result of delay in the change of oil and filter, therefore it is recommended that they be changed regularly. The Dodge Sprinter 2500 comes with various engine types that include 2.3L I4 OM601 Diesel and 2.7L Mercedes turbo-diesel hence enhancing the efficiency of the Oil Pump in regulating the oil pressure for performance. Dodge Sprinter 2500 Oil Pump plays a vital role in providing efficient and safe performance to the automobile's engine as it guarantees necessary lubrication to all the parts that are in motion. The features that set the product from its competitors include the capability for controlling circulation of oil, vital for high-revving engine types that usually require complicated lubriation methods. Due to the quality nature and efficiency of the product, the Dodge Sprinter 2500 Oil Pump plays an important role on the vehicle's framework, enhancing the meaning and standard of the Dodge trademark.

Dodge Sprinter 2500 Oil Pump Parts and Q&A

- Q: How to Service and Repair an Oil Pump on Dodge Sprinter 2500?A:Start by getting rid of the Oil Pan and unscrewing the oil pump bolts to fix and service the pump. With the chain tensioner off the oil pump, take the chain out by removing the oil pump, pickup tube and O-ring. After removing the negative Battery Cable, uninstall the oil pan and the oil pump as well. Back the pin of the thrust spindle out before locating it into the oil pump chain. Using the chain separating tool, riveting tool, thrust spindle and thrust pin, position the assembly on one oil pump chain link, install the thrust pin and the link will separate. Take out the pressed oil pump chain pin from the hole on the chain separation tool. Successful installation of the oil pump chain is vital to keep your engine free from severe troubles. If the oil pump is not oily, apply a thin layer of clean oil to the inside and then clean both the oil pickup tube and strainer before installation. Cover all sealing areas, put the oil pump onto the chain and secure the tensioner in place. Bolt the retaining bolts onto the oil pump and tighten them to 18 Nm (160 inch lbs.). Install the oil pan afterward and fill the crankcase with the right kind of engine oil. While the engine is on, be careful to avoid pulleys, belts or fans and don't wear clothes that hang loosely over your body. Fire up the engine and make sure you don't see any leaks. It's important to link the new oil pump chain to the old one using a temporary link, the outer plate and the locking element. Turn the crankshaft clockwise slowly until the two oil pump chains are in line, then remove the assembly element, outer plate and assembly link, putting the new riveted link in from the rear. Link the end of the new oil pump chain to the new riveted link, carefully assembling the riveting tool so one part is secured by a screw and the other can slide loosely on the thrust spindle. A magnet will attach the outer plate to the system. Put the new outer plate into the tool insert, place the tools over the riveted link, line up the riveting tool over the new link and press the rivet down into the insert until it reaches the tool stop. As soon as the dent holes in the outer plate have enlarged, put in a new insert on the riveting tool so it continues to hold the outer plate in place. Set the outer plate into the moving assembly insert, bring the riveting tool so that the guide's spacer webs line up and check that everything appears straight. Pull the riveting tool handle straight into the core after you have screwed it in firmly, then turn the insert so it matches the rivet. Put a rivet in each link, place the tool over the middle of the ribets, turn the spindle until it won't rotate any more and inspect the riveting, retightening them if they're loose. Do the same for the second rivet, put in the oil pump and oil pan once both rivets are in, add the right engine oil to the crankcase, attach the negative battery cable and turn on the engine without the air filter.