JeepParts

My Garage

My Account

Cart

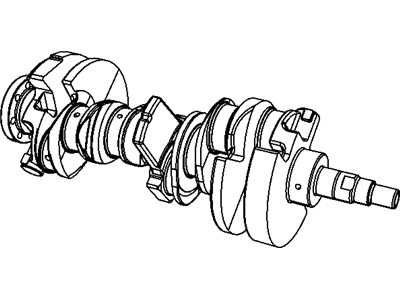

OEM 2000 Dodge Caravan Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Crankshafts found

2000 Dodge Caravan Crankshaft Part Number: 4621983AD

$299.79 MSRP: $1045.00You Save: $745.21 (72%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Crankshft

- Replaces: 4621983AB

- Item Weight: 47.30 Pounds

- Item Dimensions: 25.8 x 8.2 x 8.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4621983AD

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

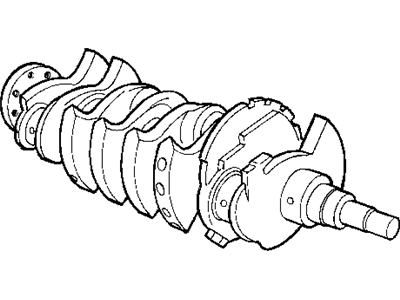

2000 Dodge Caravan Crankshaft Part Number: 4621917

Product Specifications- Other Name: Crankshft; Crankshaft, Machined

- Item Weight: 50.80 Pounds

- Item Dimensions: 23.3 x 8.8 x 8.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4621917

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2000 Dodge Caravan Crankshaft Parts and Q&A

- Q: How to Remove and Install a Crankshaft in an Engine Assembly on 2000 Dodge Caravan?A: Before you can remove the crankshaft, first remove the engine assembly from the vehicle and take it apart from the transaxle. Then, take off the flex plate and crankshaft rear oil seal and once done, raise the engine onto a repair stand with the mounting brackets. The oil filter, oil pan, timing belt cover, timing belt and oil pump all need to be taken off. You need to take out the balance shafts block, as well as all main bearing cap bedplate bolts from the engine block. With a mallet, lightly strike the bedplate free from the engine block dowel pins so that you don't affect the alignment between the cylinder block and the bedplate. Removing the bedplate at an equal rate saves the dowel pins and thrust bearing, permitting you to pull the crankshaft out of the cylinder block easily, without harming the main bearings or journals. To install, make sure the lubrication groove in the block points to the main bearing shells, allowing the oil holes in the block to connect with those in the bearing and that the tab seating is proper. Be careful not to let any oil touch the surface where the bedplate seals, because it could interrupt the sealing. Apply a little oil to the bearings and journals and then place the crankshaft into the engine, using only the recommended anaerobic sealer around the bedplate to protect against engine damage. Use a bead of Mopar Bed Plate Sealant measuring 1.5 to 2.0 mm around the cylinder block, fitting the lower main bearings into the main bearing cap/bedplate with their bearing tabs inside the bearings. The main bearing/bedplate goes in next, where the bolts are oiled and any excess is wiped away. The main bearing bedplate to engine block bolts are to be tightened just enough so the bedplate meets the cylinder block. Properly aligning the thrust bearings requires the crankshaft to be turned until the number 4 piston is at top dead center, then moved all the way backward and forward to the ends of the travel, with a suitable tool added between the crankshaft counterweight and the end of the cylinder block. Bolts must be put together and tightened one step at a time to 41 Nm before the wedge tool is removed. Tighten the bolts a second time to 41 Nm, followed by a 1/4 turn and set the main bearing bedplate to engine block bolts to 28 Nm in order. After you install the main bearing bedplate, check the crankshaft turning torque to make certain it is not over 5.6 Nm. Following assembly of the balance shaft group, oil pump, timing belt and covers, add the oil pan and oil filter. Before tightening, you should install the crankshaft rear oil seal, apply the adhesive to bolt threads, install the flex plate and fasten both parts with 95 Nm of torque. Then, fit the transaxle to the engine and tighten the connecting bolts to 101 Nm, before installing the engine assembly.