JeepParts

My Garage

My Account

Cart

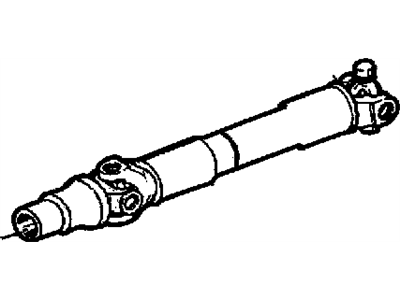

OEM 2000 Dodge Ram 2500 Van Universal Joint

U-Joint- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Universal Joint found

2000 Dodge Ram 2500 Van Universal Joints Part Number: 5014733AB

$59.52 MSRP: $130.00You Save: $70.48 (55%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Joint; Universal Joint; CV Joint; U Joint; Rear Universal Joint; U-Joint; Universal Joint Kit

- Replaces: 5014062AA, 5014733AA

- Item Weight: 1.70 Pounds

- Item Dimensions: 1.4 x 6.2 x 7.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5014733AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2000 Dodge Ram 2500 Van Universal Joint Parts and Q&A

- Q: How to service a propeller shaft equipped with a Universal Joint on 2000 Dodge Ram 2500 Van?A: There are several parts to the procedure for servicing an engine with a propeller shaft and a cardan joint. First, get rid of the propeller shaft. After that, gently tap on the bearing cap assembly using a soft drift to loosen the snap ring and remove the snap rings from both sides of the yoke. Place the yoke in an arbor press or vise with a socket that can hold the bearing cap and have the socket's grease fitting pointing up. Slide a socket of the right outer diameter over the upper bearing cap and press down to eject the lower cap. If the cap isn't able to be pulled out by hand after pressing, pat the yoke ear close to the cap to help dislodge it. After turning the yoke over, put the cross straight in the opening and push gently on its tip to remove the remaining bearings cap. Make sure the cross or bearing cap is straight while installing, to make sure you do not score the bore holes. When assembling, grease the bores inside the yoke with either EP N.L.G.I. Grade 1 or 2. Put the cross in the yokes so its lube fitting is pointing up if you have this feature. Cover the trunnion with a bearing cap and make sure the needle bearings are in line with the yoke bore as you do so. Place the bearing cap into the yoke bore until it's ready for a snap ring and install the ring at this point. For the other bearing cap, do the same and, if the joint is stiff or binding, give the yoke a light tap with a hammer to get the needle bearings properly seated. The last step is to grease the lube fitting, if present and mount the propeller shaft.