JeepParts

My Garage

My Account

Cart

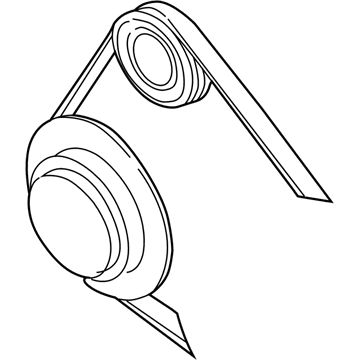

OEM 2002 Chrysler Concorde Drive Belt

Serpentine Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Drive Belts found

2002 Chrysler Concorde Serpentine Belt Part Number: 4892479AB

$48.28 MSRP: $70.90You Save: $22.62 (32%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Belt - Accessory Drive; Drive Belt; Alternator Belt; Belt; Belt Accessory Drive

- Replaces: 4573013AB

- Item Weight: 0.70 Pounds

- Item Dimensions: 12.4 x 4.1 x 1.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4892479AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2002 Chrysler Concorde Serpentine Belt Part Number: 4792071AC

$14.15 MSRP: $28.95You Save: $14.80 (52%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Belt - A/C; Serpentine Belt Drive Kit; Drive Belt; V-Belt; A/C Belt

- Replaces: 4792071AB

- Item Weight: 0.60 Pounds

- Item Dimensions: 19.6 x 4.7 x 1.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4792071AC

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2002 Chrysler Concorde Serpentine Belt Part Number: 4892173AA

$27.50 MSRP: $52.20You Save: $24.70 (48%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Belt - Alternator And Power Steering; Serpentine Belt Drive Kit; Accessory Drive Belt; Drive Belt; V-Belt; Belt; Belt Alternator And Power Steering

- Item Weight: 0.70 Pounds

- Item Dimensions: 1.0 x 4.4 x 16.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4892173AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2002 Chrysler Concorde Serpentine Belt Part Number: 4663950AF

Product Specifications- Other Name: Belt - A/C Compressor; A/C Belt

- Replaces: 4663950AD, 4663950AE, 4663950AC, 4663950

- Item Weight: 0.70 Pounds

- Item Dimensions: 24.2 x 6.1 x 0.9 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4663950AF

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2002 Chrysler Concorde Drive Belt Parts and Q&A

- Q: How to Maintain and Fix a Drive Belt on 2002 Chrysler Concorde?A: Service and repair the drive belts by starting with taking off the generator/power steering belt by loosening the tensioner pulley locknut and the belt adjusting bolt and then removing it. Generator/power steering bolt: To get to the air conditioning belt, remove the generator/power steering bolt then loosen the tensioner locking bolt and pivot bolt, but leave them in before installing the generator/power steering belt. A 1/2" drive breaker bar is recommended to turn the tensioner counter-clockwise to allow belt removal, and then the tensioner should turn clock-wise ever so slightly to release spring load. Clearing all the debris in the belt pulley grooves; you need to ensure that grooves are free of any oil, grease, and coolants; installation of the drive belt is done. Things to look at- Are there too much wear, asphalt cords showing or extreme glazing. If so, replace the belt. It should be replaced also should there be parallel cracks. By the time of putting on a new air conditioning belt, tighten the tensioner using a 1/2" drive breaker bar, remove the locking bolt, and then rest the tensioner quickly. Take out the pivot bolt, tensioner and spring in the front timing cover, put the spring arm in the new belt location, and fix back the torsion spring, the tensioner and the pivot bolt, but leave the pivot bolt to be tightened finger tight at first. Use your breaker bar to apply pressure in a counter clockwise direction until the locking bolt can be put in place and both the new belt should be fixed by turning the tensioner in an anticlockwise direction to ensure the right routing is taken. Loosen the tensioner, take out the breaker bar and it will fall at the right chunks. Snug the tensioner locking bolt and the pivot bolt to 28 Nm (250 in. lbs.), and replace the generator/power steering belt. In the case of a used air conditioning belt, same procedure is followed in installing the tensioner spring to the used belt position, this time there must be a holding of the counterclockwise pressure in releasing the locking bolt and the tension of the spring. Fit the used belt using the tensioner by turning the tensioner in the anticlock direction till it can fit on the pulleys, then you open the tensioner and apply 28 Nm (250 in. lbs.) on the locking bolt and pivot bolt. Last, replace or install the generator/power steering belt and tighten the belt adjusting bolt to the right amount of tension and tighten the tensioner locking nut. With a belt tension gauge, Special Tool 7198, the belt tension necessary in new and used belt applications can be adjusted in accordance with a belt tension chart on 2.7/3.5L engines.