JeepParts

My Garage

My Account

Cart

OEM 2002 Dodge Ram 2500 Oil Pan

Oil Drain Pan- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Oil Pans found

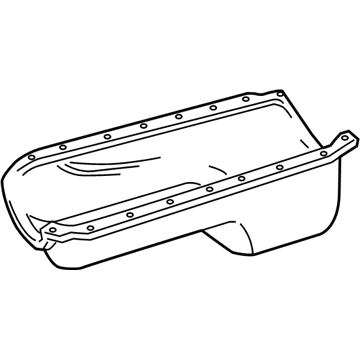

2002 Dodge Ram 2500 Oil Pan Part Number: 53020918

Product Specifications- Other Name: Pan - Engine Oil; Engine Oil Pan; Pan, Oil, Partial; Pan Engine Oil

- Item Weight: 8.60 Pounds

- Item Dimensions: 22.8 x 10.7 x 9.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 53020918

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

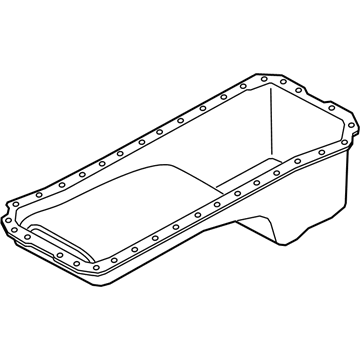

2002 Dodge Ram 2500 Oil Pan Part Number: 4762073

Product Specifications- Other Name: Pan - Engine Oil; Engine Oil Pan; Pan Engine Oil; Pan, Oil

- Item Weight: 17.30 Pounds

- Item Dimensions: 34.3 x 14.5 x 9.9 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4762073

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2002 Dodge Ram 2500 Oil Pan Part Number: 53020922AC

Product Specifications- Other Name: Pan - Engine Oil; Engine Oil Pan

- Item Weight: 7.90 Pounds

- Item Dimensions: 30.8 x 10.7 x 6.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 53020922AC

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

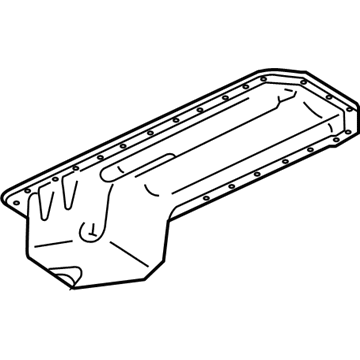

2002 Dodge Ram 2500 Oil Pan Part Number: 5080632AA

Product Specifications- Other Name: Pan - Engine Oil; Engine Oil Pan; Pan Engine Oil

- Item Weight: 13.60 Pounds

- Item Dimensions: 34.4 x 14.3 x 10.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5080632AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2002 Dodge Ram 2500 Oil Pan Parts and Q&A

- Q: How to Maintain and Fix an Oil Pan on 2002 Dodge Ram 2500?A: It's necessary to disconnect the battery negative cables and lift the car on a hoist to do the service and repairs on the oil pan. If your vehicle has a transmission and transfer case, get rid of them, then the flywheel. Open the connections on the starter and remove the starter motor and transmission adapter plate together. After draining the oil, insert the empty oil pan drain plug and fasten it with a proper sealing washer to a torque of 60 Nm (44 ft. lbs.). After unbolting the pan, break the seal around the pan, lower it a bit and detach the suction tube fasteners before you set aside the parts. Clean all the surfaces between the gasket and oil pan and cylinder block, make sure to clean T-joint areas carefully and flush the suction tube with the correct solvent. Check the oil pan, the suction tube and tube braces for any cracks or damage, then replace those that are broken or damaged. Check whether the oil drain plug and drain hole threads, plus the surface of the oil pan, are straight. Slightly fix any problem areas by hammering them with a ball-peen hammer, trying not to weld. To set up, stuff Mopar Silicone Rubber Adhesive Sealant or a compatible sealant into the T-shaped joint between these two pan rail parts. Apply another layer of sealant to the gasket, making sure it's facing the oil pan. Put the suction tube into the oil pan and guide it where it needs to be, using a new tube to oil pump gasket and install the bolts for the suction tube by hand. Screw the oil pump inlet bolts to 24 Nm (18 ft. lbs.) first and then tighten the other tube brace bolts. Apply a torque of 18 ft. lbs. (24 Nm) to the oil pan bolts following the order center, outside. Place the flywheel housing with the attached starter motor in the engine, fasten it with bolts to 60 Nm (44 ft. lbs.) torque and then link the cables to the starter motor. If your vehicle has a transmission and transfer case, reinstall them, lower the vehicle and connect the battery negative cables. Crankcase should be topped up with engine oil, the engine should be run to spot any leaks followed by a check and adjustment of oil levels.