JeepParts

My Garage

My Account

Cart

OEM 2004 Dodge Ram 1500 Intake Manifold

Engine Intake Manifold- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Intake Manifolds found

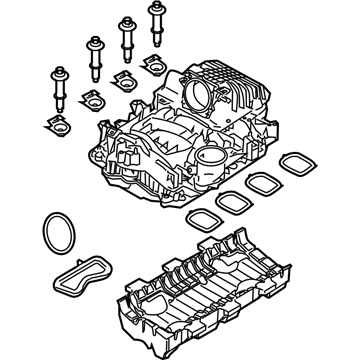

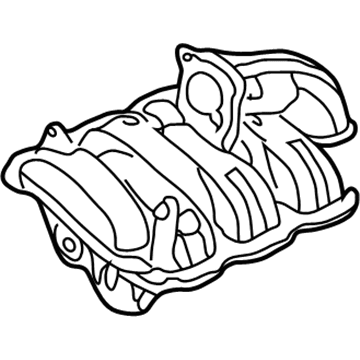

2004 Dodge Ram 1500 Intake Manifold Part Number: 5127193AF

Product Specifications- Other Name: Manifold - Intake; Engine Intake Manifold; Intake Manifold Hardware Kit

- Replaces: 5127193AC, 5127193AD, 5127193AE

- Item Weight: 21.40 Pounds

- Item Dimensions: 24.4 x 17.4 x 15.9 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5127193AF

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

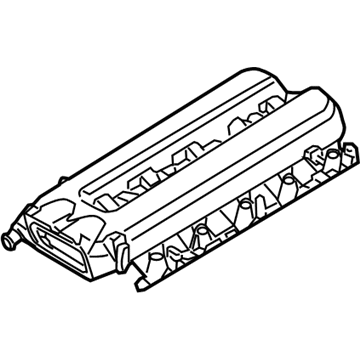

2004 Dodge Ram 1500 Intake Manifold Part Number: 5037192AE

Product Specifications- Other Name: Manifold - Intake; Engine Intake Manifold; Manifold Intake

- Item Weight: 29.90 Pounds

- Item Dimensions: 29.9 x 15.2 x 7.3 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5037192AE

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

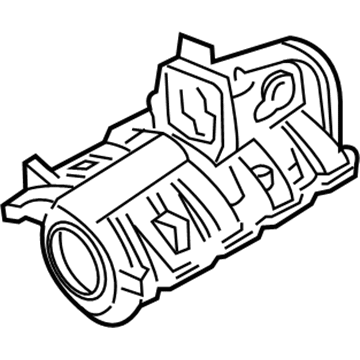

2004 Dodge Ram 1500 Intake Manifold Part Number: 53013403AD

Product Specifications- Other Name: Manifold - Intake; Engine Intake Manifold; Manifold Intake

- Item Weight: 11.90 Pounds

- Item Dimensions: 28.1 x 14.9 x 12.9 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 53013403AD

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2004 Dodge Ram 1500 Intake Manifold Part Number: 53031080AF

Product Specifications- Other Name: Manifold - Intake; Engine Intake Manifold; Manifold Intake

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 53031080AF

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2004 Dodge Ram 1500 Intake Manifold Parts and Q&A

- Q: How to Service and Repair an Intake Manifold on 2004 Dodge Ram 1500?A: Before handling the intake manifold, you should first unhook the negative cable from the battery and afterward take off the resonator assembly and air inlet hose. Afterwards, take out the throttle and speed control cables, in addition to the electrical wires for the Manifold Absolute Pressure Sensor (MAP), Intake Air Temperature Sensor (IAT), Throttle Position Sensor (TPS), Coolant Temperature Sensor (CTS) and Idle Air Control Motor (IAC). Separate the vapor purge hose, brake booster hose, speed control servo hose and positive crankcase ventilation (PCV) hose and afterward take out the generator and air conditioning compressor electrical connections. Disconnect the radio's left and right antenna straps, the ignition coil towers and release the top oil dipstick bolt, along with the attached ground strap. Let out the excess fuel from your car and take out the fuel rail, throttle body assembly and bracket. Remove the coolant from the cooling system after it reaches normal temperature, come out from the truck under the hood and unclip the heater hoses at the front cover, heater core, the tubes at the intake manifold and remove the coolant temperature sensor. Take out the intake manifold retaining nuts and bolts in the reverse order they were tightened. For installation, place the intake manifold gaskets first, add the intake manifold and use 12 Nm (105 inch lbs.) of torque on the retaining bolts, in the sequence shown. After that, attach the left and right radio suppressors, the throttle body assembly and the bracket for the throttle cable, before linking the thrWe and speed control cables to the throttle body. Fit the fuel rail and ignition coil towers into place, put on the heater hoses and tubes onto the intake manifold and rejoin the heater hoses to the heater core and engine front cover. Rearrange the electrical connections for the MAP Sensor, IAT Sensor, TPS Sensor, CTS Sensor, IAC Motor, the ignition coil in every cylinder port and the fuel injectors in every port. Once done, top off the dipstick tube with the retaining bolt, secure the ground wire, attach the rapid disconnect connectors for the generator, put on the vapor purge, brake, speed servo and PCV hoses, add coolant to the system, replace the resonator, connect the tube to the inlet air and attach the negative battery cable.