JeepParts

My Garage

My Account

Cart

OEM 2004 Dodge Ram 2500 Fuel Injector

Gas Injector- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Fuel Injectors found

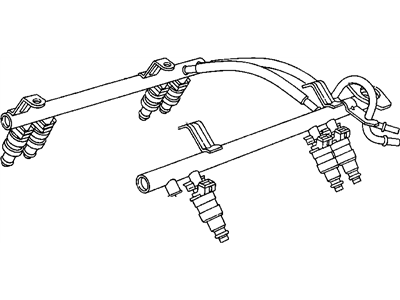

2004 Dodge Ram 2500 Injector Part Number: R8004082AC

$688.83 MSRP: $820.00You Save: $131.17 (16%)Ships in 1 Business DayProduct Specifications- Other Name: Injector - Fuel; Common Rail Injector; Fuel Injector; Injector Fuel

- Replaces: R8004082AB, R5086894AA, R8004082AA

- Item Weight: 2.00 Pounds

- Item Dimensions: 3.2 x 3.3 x 3.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- Require Quantity: 6

- SKU: R8004082AC

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

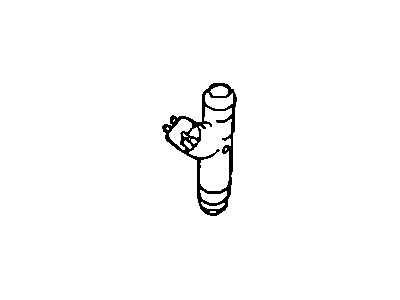

2004 Dodge Ram 2500 Injector Part Number: 53032713AB

Product Specifications- Other Name: Injector - Fuel; Injector Fuel

- Replaces: RL032713AB

- Item Weight: 0.50 Pounds

- Item Dimensions: 1.6 x 1.6 x 3.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 53032713AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2004 Dodge Ram 2500 Fuel Injector Parts and Q&A

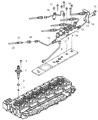

- Q: How Can Fuel Injector Servicing and Repair Prevent Engine Damage on 2004 Dodge Ram 2500?A: Proper handling during the service and fix of fuel injectors is needed since using the incorrect type can cause engine damage and there are only two different kinds that do not mix. You should start by taking the negative battery cables off and separating their ends, then get rid of the breather assembly and valve cover. Disconnect the high-pressure fuel line from the rail on the fuel injector and take out the retaining nut from all the connector tubes. To remove the connectors from the cylinder head, use the special tool number 9015. Remove the exhaust rocker arm next and then pull out the wire nuts from the tops of the injectors on the solenoid. Remove the hold-down bolts from all fuel injectors being serviced. Replace one housing bolt temporarily with the mounting stud on the tool, lock it into place, install the tool and keep the nut on the handle loose for it to pivot. Set the clamshell halves over the fuel injector and slide the retainer sleeve to join them, pressing the extractor slowly to lift the injector straight from the block. Get rid of the injector sealing washer which comes with the injector at its tip point. When installing, check the new injector for any damage, clean the area around the cylinder head and put in a fresh 1.5 mm shim at the base. Put on a small amount of engine oil. Slide an o-ring on the injector, cover it with some clean engine oil and place the high-pressure port of the injector toward the intake manifold when installing it into the head. Tighten the hold-down clamp bolts by 5 Nm, loosen them and continue to thread them. First, assemble the high-pressure connector and retaining nut, tightening them with 15 Nm and then gradually tighten each injector hold-down bolt to 10 Nm. Finally, tighten the high-pressure connector to 50 Nm. Connect the injector solenoid wires and tighten the nuts to 1.25 Nm; don't overtighten them. Replace the exhaust rocker arm, set the valve lash and attach the high-pressure fuel line, making sure the connector nut is held by a secondary wrench. After that, put the valve cover back, install the breather assembly and reconnect the negative battery cables.