JeepParts

My Garage

My Account

Cart

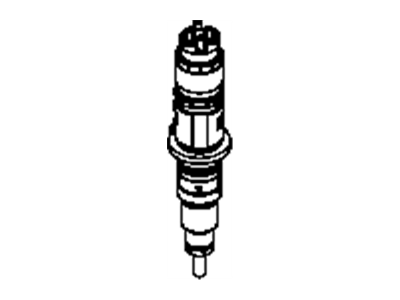

OEM Dodge Ram 2500 Fuel Injector

Gas Injector- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

16 Fuel Injectors found

Dodge Ram 2500 Injector Part Number: R8069384AA

$722.44 MSRP: $868.00You Save: $145.56 (17%)Ships in 1 Business DayDodge Ram 2500 Injector Part Number: RL032142AC

$70.46 MSRP: $105.00You Save: $34.54 (33%)Dodge Ram 2500 Injector Part Number: R4761596

$156.73 MSRP: $198.69You Save: $41.96 (22%)Ships in 1-2 Business DaysDodge Ram 2500 Injector Part Number: 53030778AB

$91.75 MSRP: $139.00You Save: $47.25 (34%)Dodge Ram 2500 Injector Part Number: R8002012AD

$716.94 MSRP: $1145.00You Save: $428.06 (38%)Ships in 1 Business DayDodge Ram 2500 Injector Part Number: R8004082AC

$688.83 MSRP: $820.00You Save: $131.17 (16%)Ships in 1 Business Day

Dodge Ram 2500 Injector Part Number: 53032713AB

Dodge Ram 2500 Injector Part Number: RL031740AA

Dodge Ram 2500 Injector Part Number: RL031571

Dodge Ram 2500 Injector Part Number: 53030262AB

Dodge Ram 2500 Injector Part Number: 5018177AA

Dodge Ram 2500 Injector Part Number: 5013848AA

Dodge Ram 2500 Injector Part Number: 5013847AA

Dodge Ram 2500 Injector Part Number: 4882120

Dodge Ram 2500 Injector Part Number: 4856671

Dodge Ram 2500 Injector Part Number: R5135790AF

$684.94 MSRP: $795.00You Save: $110.06 (14%)

Dodge Ram 2500 Fuel Injector

Choose OEM Fuel Injector that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Fuel Injector follows strict manufacturing steps to lock in quality and fit. If your Dodge Ram 2500 matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Ram 2500 parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

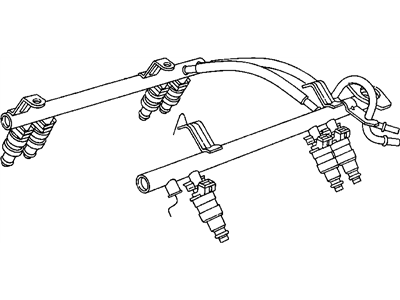

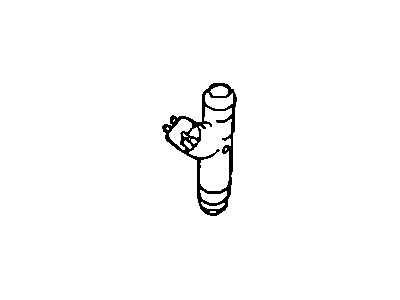

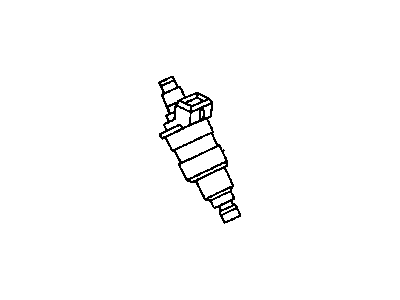

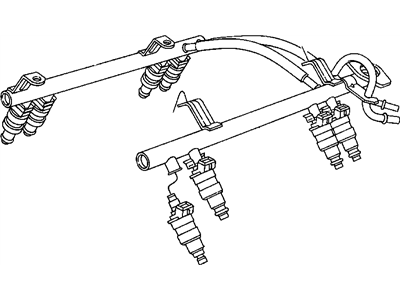

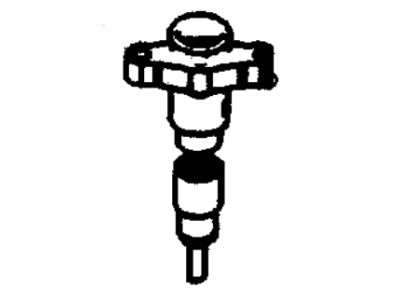

The Fuel Injector in Dodge Ram 2500 vehicles' importance lies in spewing fuel into the engine cylinder to combine with air to create a combustible mix for the engine. This system works under the command of the engine control unit (ECU) that controls the timing and the quantity of fuel injected depending on the load of the engine. Dodge Ram 2500 employs direct as well as indirect fuel injection system. Direct injection supplies fuel in the cylinder while indirect injection first supply air/fuel mixture in the cylinder. These adjustments help in improving the performance as well as efficiency of the engine but at the same time, they are also vulnerable to problems such as blockage or even development of the cracks hence resulting to poor running power of the engine. It is also important to service the Dodge Ram 2500 frequently and replace faulty fuel injectors on time to ensure optimality of operations.

Dodge Ram 2500 Fuel Injector Parts and Q&A

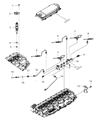

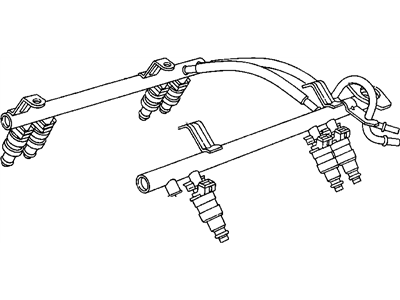

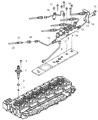

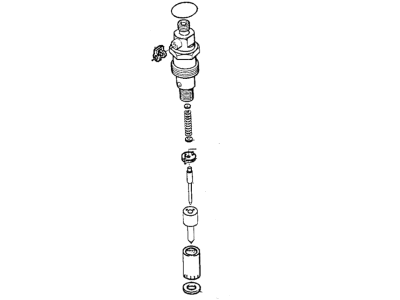

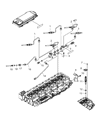

- Q: How to Remove and Install a Fuel Injector in a Cylinder Head on Dodge Ram 2500?A:Between the intake and Exhaust Valves, at the top of the cylinder head, you'll find the fuel injectors. Start by undoing the negative cables from the batteries and then put a cover on their ends. Aircraft fuel injectors are connected to high-pressure fuel lines with steel tube sealed by an O-ring. If you take out the injector from either #1 or #2 cylinder, first take away the intake manifold air heater assembly; if from the #5 cylinder, make sure to remove the engine lifting bracket. Wipe down the space around the injector and high-pressure lines, take the required high-pressure fuel lines off one at a time and don't bend them and seal any open connections. After taking off the valve cover, place Special Tool 8324 onto the connector tube so you can tug it from the cylinder head, being sure to remove the tube while it is still above the fuel injector to keep it safe. Pull out the O-ring from the injector connector tube and unbolt the hold down clamp from the front of the clamp, then move the injector clamp on the rear bolt off its shoulders. Use the supplied Special Tool 8318 to guide an injector wire through the fuel injector from the top and tighten the nut to remove the injector from the cylinder head. After the pull, throw away the old O-ring and copper sealing washer found underneath the injector inside. Examine the condition of the fuel injector, test its pressure if needed and brush and blow out the injector bore with a Cummins wire tool followed by compressed air. The sealing washer should measure 1.5 mm (.060") and you should install it on the injector at its lowest point with a thin layer of clean engine oil. Install an O-ring and coat it with clean engine oil before putting the fuel inlet hole in line with the injector connector tube. Put the fuel injector into the cylinder head bore using pressure only, then set up the fuel injector hold down clamp and tighten the opposite bolt to 10 Nm (89 in. lbs.). Replace the old O-ring on the fuel injector connector tube, set it in the cylinder head and attach the two high-pressure fuel hoses, applying the proper tightness to stop any possible leaks. At the end, install the valve cover, fit the intake manifold air heater assembly if you have one, tighten the engine lifting bracket bolts to 77 Nm (57 ft. lbs.), attach the negative battery cables and bleed the high-pressure lines.

- Q: How to Service and Repair a Fuel Injector for 3.7/4.7/5.7L Engines on Dodge Ram 2500?A:Before servicing or repairing a fuel injector on the 3.7/4.7/5.7L engines, take off the Fuel Rail. Then, unconnect the clip(s) holding the fuel injector(s) to the fuel rail (2).