JeepParts

My Garage

My Account

Cart

OEM Chrysler Concorde Exhaust Valve

Exhaust Muffler Valve- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Exhaust Valves found

Chrysler Concorde Valves Part Number: 4663902

$29.53 MSRP: $43.15You Save: $13.62 (32%)Ships in 1-2 Business DaysChrysler Concorde Exhaust Valve Part Number: 4892094AA

Chrysler Concorde Exhaust Valve

Choose OEM Exhaust Valve that meet Chrysler factory standards. Chrysler designs and tests every component for precision and durability. Each Exhaust Valve follows strict manufacturing steps to lock in quality and fit. If your Chrysler Concorde matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Concorde parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

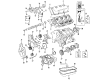

Exhaust Valve is one of those imperative features which facilitate efficient and solid performance of Chrysler Concorde cars. This exhaust valve enables the proper expulsion of burnt gases from the engines cylinders for optimum performance of the engine, this helps to eliminate problems like misfiring, low power and many others. High quality and long lasting, the Exhaust Valve suits a range of Chryslers that belong to the Concorde series, and thus is a perfect vehicle for keeping the engines of the Concorde series smooth running. The exhaust valve serves an important functional and safety role in any efficiently running car engine as it regulates the temperatures and allows the expulsion of toxic gases. Chrysler has engineered the features of the Concorde Exhaust Valve to perfection so as to suit the specifications of the market. Some of these include better sealing ability, wear and tear resistance and such that have set Exhaust Valve from other ordinary similar competitors in the market. Similarly, the longitudinal engine arrangement integrated in the Concorde's design also supports the job of exhaust valve by facilitating better exhaust flow pattern. All in all it can be concluded that the Exhaust Valve is an important component that contributes to the effectiveness as well as safety of Chrysler Concorde vehicles and can not be left without attention in terms of the car's engine performance and durability. As for the Exhaust Valve, with its tested performance a lot of car owners and mechanics go for it to have their Chrysler Concorde tuned up.

Chrysler Concorde Exhaust Valve Parts and Q&A

- Q: How to Service and Repair Exhaust Valve and Intake Valves on Chrysler Concorde?A:The first part of servicing valves is to take out both the cylinder head(s) and the valve spring. To ensure the valves are not harmed, first clear out any burrs on the valve stem grooves before taking the old valves out. Identify every valve as you take it out to ensure it is correctly reinstalled where it were before. Make sure the valves are well-cleaned and visually checked and where they are burned, warped or cracked, replace them. Maintain your valve stems by checking for wear; you should find they are chrome plated and should not receive any polishing. To tackle the valve guides, wipe away all carbon and varnish using a suitable guide cleaner. Then install a valve in the cylinder head so it's a 15 mm (0.590 in.) distance from the valve seat, using a hose piece to keep it in place. Screw over the dial indicator onto the cylinder head at a right angle to the valve stem and cycle the valve over its travel. Replace the cylinder head if the distance between the stem and guide is greater than allowed or if the guide is loose. Before you install, oil the valve stems and then insert them into the cylinder head. If you have reground the valves or seats, check the height of each valve tip in the cylinder head; if the intake valve tip height is over 47.59 mm (1.8737 in.) or the exhaust valve tip height is over 49.14 mm (1.9347 in.), keep lowering their heights until they fall within specifications, starting at the level of the cylinder head surface to the top of the valve stem. Now, put the valve spring in place.

- Q: How Do Exhaust Valves and Intake Valves Impact the Refacing Process and Specifications on Chrysler Concorde?A:The turning of the intake and exhaust valves has a 44.5 to 45 degree face angle, while the seats for these valves have a face angle between 45 and 45.5 degrees. Once the job of refacing the valve ends, check how much margin remains. When working with valve faces, carefully choose the correct valve guide pilot so that reshaped stones are precisely flat. Make certain the valve seat is within limits by measuring its concentricity with a dial indicator (total runout should not go past 0.051 mm or 0.002 inch). Coat the valve seat with Prussian blue, insert the valve while it's in place and rotate it gently; if the blue is transferred to the valve face center, the valve is making smooth, unbroken contact. If you can see bothering the top edge, press lower by 15 degrees with a stone and for the bottom edge, raise it by 65 degrees. Fixing worn-out or burned valve seats only works if their angle and width are correct; otherwise, the whole cylinder head needs replacing. Intake seats should be 1.00 to 1.50 mm wide (0.0394 to 0.0591 inch) and exhaust seats must be 1.25 to 1.75 mm wide (0.049 to 0.069 inch). When the job is complete, smear the stems of the corresponding valve springs with clean engine oil and gently place them in the cylinder head to measure their position. If the valves have been refaced, make sure the tips aren't sticking out further than the rules; if they do, grind the valve tip to suit the specifications, measured from the surface of the cylinder head to the top of the valve stem. Install the rubber seal and its garter spring so they're over the valve stems and past the top of the valve guides. Wedge the valve and retainer springs on the spring seat, use a compressor to compress them and put the retainer locks into place. Check the space between the top of the spring seat and the opposing spring retainer; if it is greater than 38.75 mm (1.5256 inch), add a 0.762 mm (0.030 inch) spacer in the head counterbore under the seat as shown in Figure 9-19.