JeepParts

My Garage

My Account

Cart

OEM Dodge Challenger Piston Ring Set

Piston Ring- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Piston Ring Sets found

Dodge Challenger Piston Rings Part Number: 68092206AA

$88.21 MSRP: $131.00You Save: $42.79 (33%)

Dodge Challenger Piston Rings Part Number: 68078776AA

$180.15 MSRP: $269.00You Save: $88.85 (34%)Ships in 1-2 Business Days

Dodge Challenger Piston Rings Part Number: 5159661AA

Dodge Challenger Piston Rings Part Number: 4897035AB

Dodge Challenger Piston Rings Part Number: 68046210AB

$241.33 MSRP: $359.00You Save: $117.67 (33%)Dodge Challenger Piston Rings Part Number: 68262329AD

Dodge Challenger Piston Rings Part Number: 68262329AC

$118.97 MSRP: $176.00You Save: $57.03 (33%)

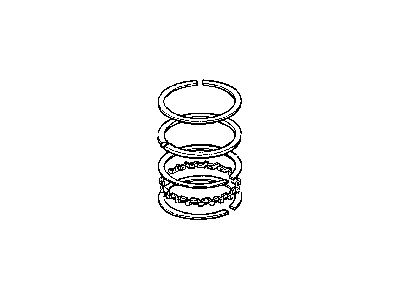

Dodge Challenger Piston Ring Set

Choose OEM Piston Ring Set that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Piston Ring Set follows strict manufacturing steps to lock in quality and fit. If your Dodge Challenger matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Challenger parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

Dodge Challenger Piston Ring Set Parts and Q&A

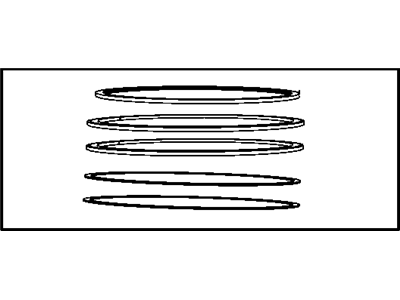

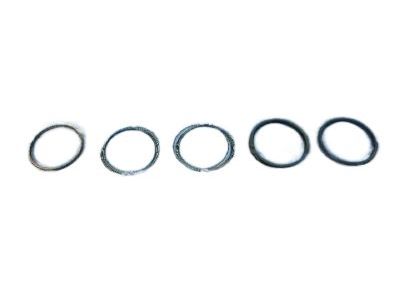

- Q: How to remove and replace a Piston Ring Set on Dodge Challenger?A:The process to replace the Piston rings is to first take out the piston and connecting rod. Afterward, pull the piston aside and remove the two piston rings with a ring expander tool. Following that, get rid of the top oil control ring side rail, then do the same for the bottom oil control ring side rail and lastly extract the oil control ring expander.

- Q: How to Check Piston Ring Set Clearances to Prevent Engine Damage on Dodge Challenger?A:Make sure to inspect the ring clearance before putting in either new or used rings to keep engine components from becoming damaged. Begin by cleaning the bore and install the ring, putting it into the bore so that you can measure the interval with the ring being 12 mm or 0.50 inch above the bottom of the cylinder. Square the ring with a Piston in the cylinder bore and then lower it. Measure the distance between the ring and groove with a feeler gauge and if it is out of specification, replace the ring. Assemble the ring so both sides are clean and smooth, then check the ring side clearance between the ring and the ring land with a feeler gauge; replace any ring that doesn't fit as specified. Be certain that the marks on the ring face up and push it onto the piston so it remains free as it revolves. First, push the oil ring expander through the hole, then press down the bottom side rail between the expander and the piston ring groove until it's in place and do the same for the upper side rail. Put No. 2 intermediate piston ring and No. 1 upper piston ring in place with the help of a piston ring installer. Place the area between the oil ring expander and 3rd ring at the 5 position, between the oil ring lower part and first rail at the 4 position, between the oil ring upper part and second rail at the 1 position, between the second compression ring and 3rd ring at the 5 position and between the top compression ring and compressor cover at the 2 position.