JeepParts

My Garage

My Account

Cart

OEM Dodge Challenger Piston

Engine Pistons- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

15 Pistons found

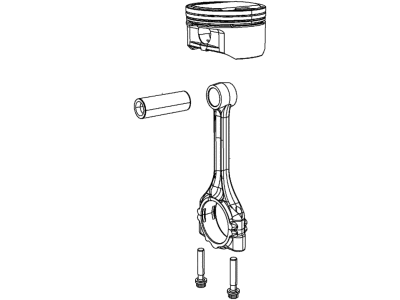

Dodge Challenger Connecting Rod Part Number: 68090672AA

$291.72 MSRP: $439.00You Save: $147.28 (34%)

Dodge Challenger Connecting Rod Part Number: 68090673AA

$295.71 MSRP: $435.00You Save: $139.29 (33%)Ships in 1-2 Business Days

Dodge Challenger Connecting Rod Part Number: 53022257AE

$221.23 MSRP: $328.00You Save: $106.77 (33%)Dodge Challenger Piston Part Number: 68262321AA

$605.54 MSRP: $912.00You Save: $306.46 (34%)Dodge Challenger Piston Part Number: 53010809AF

$504.99 MSRP: $761.00You Save: $256.01 (34%)Ships in 1-2 Business DaysDodge Challenger Connecting Rod Part Number: 53010928AD

$509.41 MSRP: $769.00You Save: $259.59 (34%)Ships in 1-2 Business DaysDodge Challenger Connecting Rod Part Number: 53022258AE

$216.40 MSRP: $318.00You Save: $101.60 (32%)Ships in 1-2 Business Days

Dodge Challenger Piston Part Number: 68031891AD

Dodge Challenger Piston Part Number: 68031890AD

Dodge Challenger Piston Part Number: 68262320AA

$627.46 MSRP: $912.00You Save: $284.54 (32%)Dodge Challenger Piston Part Number: R4892194AB

Dodge Challenger Piston Part Number: 53022258AC

Dodge Challenger Piston Part Number: 53022257AC

Dodge Challenger Piston Part Number: 53010808AF

$517.54 MSRP: $752.00You Save: $234.46 (32%)Dodge Challenger Connecting Rod Part Number: 53010927AD

$527.85 MSRP: $769.00You Save: $241.15 (32%)

Dodge Challenger Piston

Choose OEM Piston that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Piston follows strict manufacturing steps to lock in quality and fit. If your Dodge Challenger matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Challenger parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

Dodge Challenger Piston Parts and Q&A

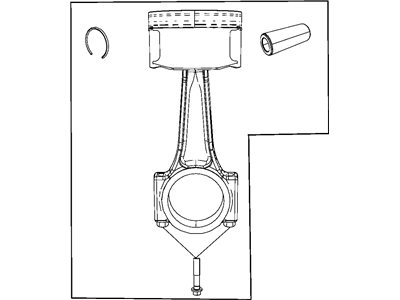

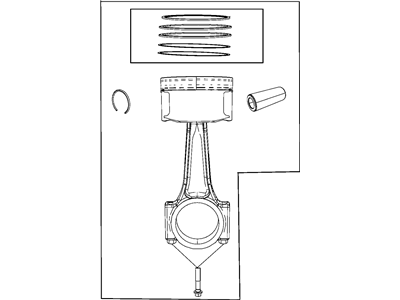

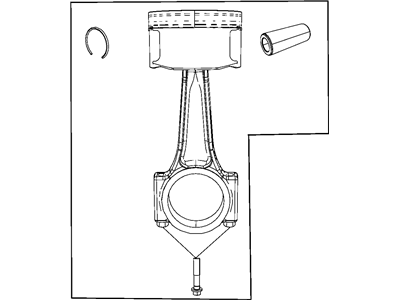

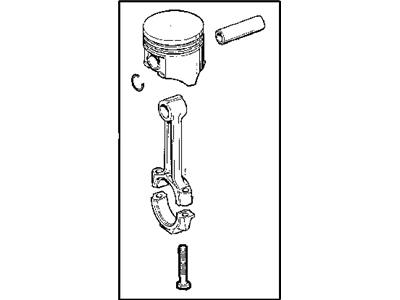

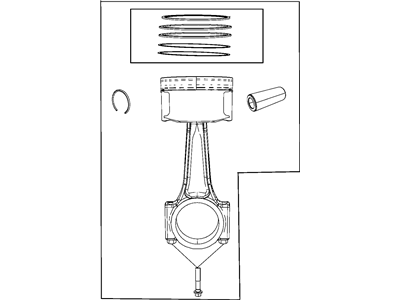

- Q: How to Remove and Replace a Piston and Connecting Rod on Dodge Challenger?A:Before taking out and installing the piston and connecting rod, carry out the fuel system pressure release step and remove the negative cable from the battery. Lift the engine covers, unscrew the clamp at the Throttle Body to disconnect the air duct and disconnect the sensor's electrical connector. Get rid of the makeup air hose and take away the air cleaner housing by giving the retaining bolt a twist. After that, take out the cylinder head(s) and prop up the vehicle. Unscrew the nuts of the engine mounts and loosen the bolts holding the steering gear. Next, put the gear aside out of the way. After lifting the vehicle and taking out the engine oil dipstick and tube, place Engine Lift Fixture 8984A, Engine Lift Adapter 8984-UPD and Engine Support Fixture 8534B . Before removing the Oil Pan, elevate the engine so it clears the oil pan, then support the vehicle again to finish the removal of the oil pan. Raise the vehicle and take off the timing chain cover. If the ridge is too high, take it out using a trustworthy ridge reamer, while covering the iron tops of the pistons. After marking the rod and bearing cap's positions, keep the permanent ink or scribe tool away from the piston oil cooler jets, the fractured rod and cap joint face areas and the crankshaft journals. Pistons and connecting rods should be taken from the cylinder block's top, with the crankshaft being rotated to position every connecting rod in the right spot in the bore. Once the cap is removed, carefully free the piston from inside the cylinder bore for every piston. When you've removed the piston pin, place the bearing cap on the connecting rod to keep it safe and get the piston rings off of the piston(s), starting from the top ring down.

- Q: How to Prepare for Installing New Piston Rings on Dodge Challenger?A:Before you put used rings back in or install new rings, check the available room for the rings and wash out the ring grooves so there aren't any defects. Check that the space between the piston rings is the proper size, then you should install the piston rings. Dip the rings and piston part in clean engine oil, place the ring compressor over them and make sure they remain where they belong as you tighten it. Apply clean engine oil to the Rod Bearing and fix it onto the end of the connecting rod. Both pistons have an "F" or arrow raised which should point towards the front of the engine when installed. Rinse the cylinder bore to remove debris, then apply clean oil inside it, after which rotate the Crankshaft to center the journal of the connecting rod within the bore. Put the piston and rod into the cylinder bore, making sure the connecting rod fits over the crankshaft journal as you slowly tap the piston down with a hammer handle. Clean the connecting rod cap, add some clean engine oil and place the bearing over it. Be sure to always match the correct bearing up with the correct rod cap, as they are not the same. Place clean engine oil on the joints between the hands and the pedals, then set the rod cap so the broad side points towards the crankshaft and the two skinny sides align. After pulling out the Rod Bolts, be sure to replace them and grease each bolt shaft with clean oil before putting them back and tightening to 45 Nm plus 60°. Fit the timing chain cover, the new Oil Pan gasket or windage tray and the oil pan and next, put in the engine oil dipstick tube and dipstick. Have an assistant lower the car and then use the Engine Lift Fixture 8984A and Engine Lift Adapter 8984-UPD to take the engine into position. Once there, take away the fixtures. Lift the vehicle, position the steering gear, place on the mounting bolts and tighten to 95 Nm. Secure the engine mount nuts with 95 Nm of torque and then lower the whole vehicle. Set the cylinder head(s) and the Intake Manifold, install the air cleaner housing, add the retaining bolt and effectively tighten it. Connect the air hose, air sensor connector and the air duct to the Throttle Body and tighten the clamp to 3 Nm. Add oil to the engine, place the engine covers in place and fasten the negative Battery Cable.