JeepParts

My Garage

My Account

Cart

OEM Dodge Intrepid Brake Disc

Disc Rotor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Brake Discs found

Dodge Intrepid Rotor, Front Part Number: 4779133AC

$91.14 MSRP: $145.00You Save: $53.86 (38%)Ships in 1-2 Business DaysDodge Intrepid Rotor, Rear Part Number: 4779111AC

$46.03 MSRP: $83.35You Save: $37.32 (45%)Ships in 1-2 Business DaysDodge Intrepid Rotor, Front Part Number: 4755028

$25.52 MSRP: $32.36You Save: $6.84 (22%)Ships in 1-2 Business DaysDodge Intrepid Rotor, Front Part Number: 4779101AB

Dodge Intrepid Rotor, Rear Part Number: 4779018

Dodge Intrepid Rotor, Rear Part Number: 4582225

Dodge Intrepid Rotor, Front Part Number: 4779020AB

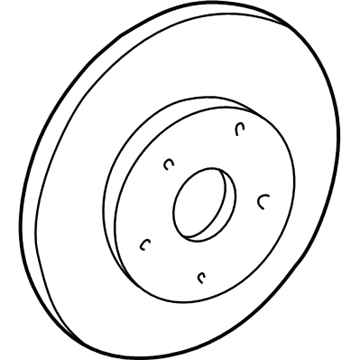

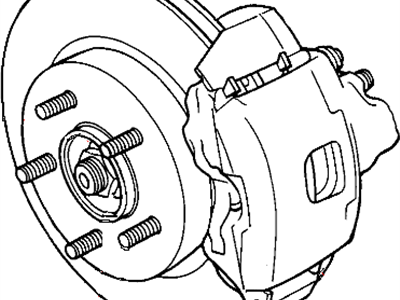

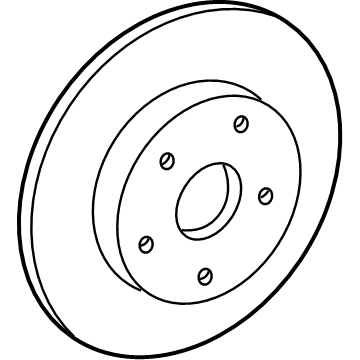

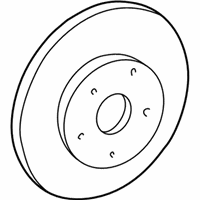

Dodge Intrepid Brake Disc

Choose OEM Brake Disc that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Brake Disc follows strict manufacturing steps to lock in quality and fit. If your Dodge Intrepid matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Intrepid parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

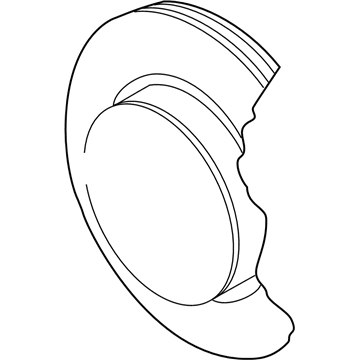

Brake systems of the Dodge Intrepid automobile employ the reliable and effective Dodge Intrepid Brake Disc across multiple Intrepid models that operated during the 1993-2004 production period. The main material in these Brake Discs is gray iron alongside features of advanced design such as fins or vanes that enable effective heat dissipation for peak braking efficiency. The Dodge Intrepid Brake Disc serves multiple engine types such as the 3.3 L and 3.5 L V6 engines which allows drivers to choose power systems in combination with safety features. The Dodge Intrepid receives better heat control and quieter operation from drilled or slotted Brake Disc systems which improve overall driving smoothness. Proper care of Brake Discs must occur regularly because it prevents safety-compromising issues such as warping and rusting formation. The Dodge Intrepid achieves its mission of protecting drivers and their passengers through its four-wheel disc brake system working alongside strong suspension and safety design elements. The Dodge automobile Brake Disc distinguishes itself in the automotive market because its durable performance combination makes it a dependable system for drivers who focus on vehicle effectiveness and security. The the automaker car Brake Disc enhances driving dynamics of the model thus maintaining its position as a preferred model among full-sized sedans.

Dodge Intrepid Brake Disc Parts and Q&A

- Q: Should You Reface the Brake Disc with Every Brake Pad Replacement on Dodge Intrepid?A:Disc refacing is not a given whenever you change Brake Pads, but extreme care should be taken during servicing so the disc stays in the needed range. When the disc surface is very meaning, curved or if someone mentions problems with rough brakes or pedal vibration, refacing the disc with a wheel brake lathe or changing it with a new disc is the solution. If you want to reduce runout, use a brake lathe that fits onto the hub, as it trues the disc in place of the hub and bearing. Every disc will show the minimum thickness allowed, marked on its untouched side, showing the least amount the disc should be machined. The thickness of the disc at this point must not be machined below the recommended level. Before you install anything, check that both the brake disc face and hub adapters are clean, rust free and not contaminated. While brake lathe operation, strictly go by what the manufacturer advises and grind two sides together to avoid a slanted or rough disc cut. The TIR and thickness limits should always be maintained during refacing which means operators of disc turning equipment must pay close attention to their work.

- Q: What Are the Key Factors to Consider When Servicing a Brake Disc on Dodge Intrepid?A:For proper braking, the rotor should be serviced within allowable limits whenever you replace your Brake Pads. Should the rotor be severely scarred, twisted or when braking causes pedal pulsation or roughness, it needs to be remachined on the vehicle using a hub-mounted tool or changed out with a new one. This way works well to keep runout down, since it grooves the rotor to the hub and bearing. You will find minimum thickness markings on all rotors at an un-machined section, indicating how thin the brake rotor can be machined. It is significant that rotor thickness should not be machined below the minimum given limit. Check for chips, rust or debris on the rotor face and hub adapters before you fit any new brake parts. As you work on the lathe, be sure to read the operating manual often and machine both sides at the same time, to ensure the rotor does not get a tapered or uneven result. When refacing, make sure the Total Indicator Reading (TIR) stays at 0.08 mm (0.003 inch) and the thickness variation is less than 0.013 mm (0.0005 inch), so caution is needed when turning the rotor.