JeepParts

My Garage

My Account

Cart

OEM Dodge Ram 1500 Van Drive Shaft

Axle Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Drive Shafts found

Dodge Ram 1500 Van Drive Shaft Part Number: 52105713AA

Dodge Ram 1500 Van Drive Shaft Part Number: 52105678AC

Dodge Ram 1500 Van Drive Shaft Part Number: 52105412AA

Dodge Ram 1500 Van Drive Shaft Part Number: 52105411AC

Dodge Ram 1500 Van Drive Shaft Part Number: 52105410AA

Dodge Ram 1500 Van Drive Shaft

Choose OEM Drive Shaft that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Drive Shaft follows strict manufacturing steps to lock in quality and fit. If your Dodge Ram 1500 Van matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Ram 1500 Van parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

Dodge Ram 1500 Van Drive Shaft Parts and Q&A

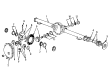

- Q: How to accurately check Drive Shaft alignment for a one-piece propeller shaft on Dodge Ram 1500 Van?A:To align the driveline, safely raise the car or truck by its axles and support it level, so the wheels and propeller turn while it is resting on the stands. Get rid of all external bearings or snap rings before you fit the inclinometer base to the shaft. Turn the shaft so the transmission/transfer case output yoke bearing cap is beneath the shaft and take all measurements at the front and the rear. Place the inclinometer so it is parallel to the shaft on the bear cap, center the bubble in the sight glass and record your results to obtain the Output or Transmission Yoke Angle. After that, rotate the propeller shaft by 90 degrees and mount the inclinometer parallel to the shaft on the yoke bearing cap, guiding the bubble to center so the reading shows the angle of the propeller shaft. The transmission output operating angle is found by subtracting the smaller value from the larger. You should then move the propeller shaft 90 degrees and lay the inclinometer on the pinion yoke bearing cap in line with the shaft, adjusting the bubble to center it and measure the angle. Subtract the smaller value from the larger one which gives you the axle Input Operating Angle. It is important that the operating angles of the U-joint are well canceled, are no more than 3° and that the propeller shaft has a continuous operating angle of at least 1/2 of a degree.

- Q: How to Maintain and Repair a Drive Shaft on Dodge Ram 1500 Van?A:Before servicing the drive/propeller shaft, remove any impurities from the universal joints using solvent and wire brush. After that, check the yokes for signs of distortion, notice any cracks and make sure the bearings are not worn.