JeepParts

My Garage

My Account

Cart

OEM Dodge Ram 2500 Van Wheel Hub

Wheel Axle Hub- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Wheel Hubs found

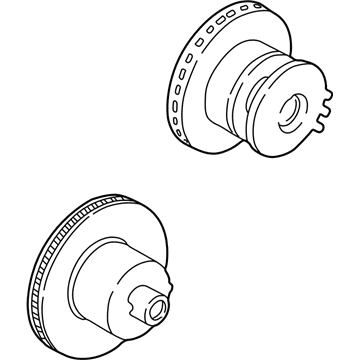

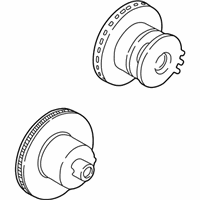

Dodge Ram 2500 Van Hub & Rotor, Front Part Number: 52009414AB

$81.94 MSRP: $103.87You Save: $21.93 (22%)Ships in 1-2 Business DaysDodge Ram 2500 Van Hub & Rotor, Front Part Number: 52009414

$87.25 MSRP: $110.61You Save: $23.36 (22%)Ships in 1-2 Business DaysDodge Ram 2500 Van Hub & Rotor, Front Part Number: 52009415AC

Dodge Ram 2500 Van Wheel Hub

Choose OEM Wheel Hub that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Wheel Hub follows strict manufacturing steps to lock in quality and fit. If your Dodge Ram 2500 Van matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Ram 2500 Van parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

Dodge Ram 2500 Van Wheel Hub Parts and Q&A

- Q: How to service and repair the wheel hub and bearing on Dodge Ram 2500 Van?A:Start by elevating the car, removing the wheel and tire and taking out the disc brake caliper when servicing the wheel hub and bearing. Now, get rid of the dust cap, cotter pin, nut lock, nut and washer from the spindle and then gently pull off the hub/rotor so the inner bearing and seal retain their integrity when pulling them away from the threaded spindle. Pull the seal and inner wheel bearing off the hub/rotor, then take out the bearing cups by pressing the pin punch into them. Begin installation by driving the bearing cups in place using a proper size driver, add Mopar Wheel Bearing Grease to the inner part of the hub, clean the inner and outer bearings and install the inner bearing along with a new seal. Visually scan the spindle for burrs and roughness and slide it freely to ensure it doesn't have any rough parts. If it does, remove them and apply lubricant. Slide the hub/rotor onto the spindle, add the outer wheel bearing, a washer and then the retaining nut. Apply 48 Nm (35 ft. lbs.) of torque to the nut while the hub/rotor spins, then stop and release all the pre-load pressing on your bearings. After that, tighten the nut to 3 Nm (25 in. lbs.), lock the nut system in place and add a new cotter pin so that the end play measures 0.25 - 0.076 mm (0.001 - 0.003 inch). Dust the cap, coat the inside with oil without going overboard and put the cap back on. Pick up the brake caliper, install it, put on the wheel and tire and then lower the car.