JeepParts

My Garage

My Account

Cart

OEM Dodge Ram 3500 TPMS Sensor

Tire Pressure Monitoring System Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 TPMS Sensors found

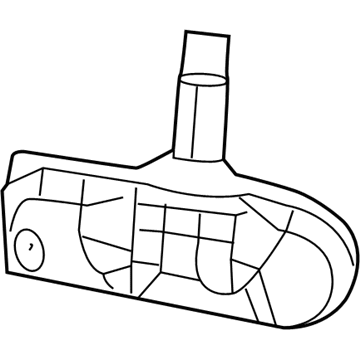

Dodge Ram 3500 TPMS Sensor Part Number: 68241067AB

$106.84 MSRP: $160.00You Save: $53.16 (34%)Ships in 1-2 Business Days

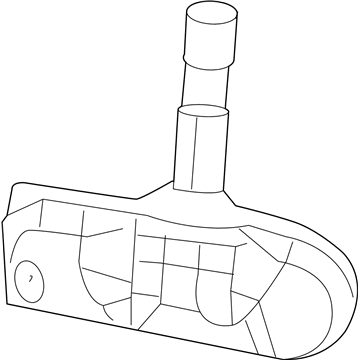

Dodge Ram 3500 TPMS Sensor Part Number: 56029319AC

$67.98 MSRP: $101.00You Save: $33.02 (33%)

Dodge Ram 3500 TPMS Sensor

Choose OEM TPMS Sensor that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each TPMS Sensor follows strict manufacturing steps to lock in quality and fit. If your Dodge Ram 3500 matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Ram 3500 parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

Dodge Ram 3500 TPMS Sensor Parts and Q&A

- Q: How to Install a TPMS Sensor on Dodge Ram 3500?A:You should update seal 2 and metal washer 1 before inserting the Tire Pressure Monitoring (TPM) Sensor in order to maintain a good seal at base of sensor valve stem 6. Make sure to wipe around the hole on wheel 5 where you will mount the sensor or valve and be certain that the wheel's surface is not damaged. To not damage the sensor antenna strap, hold the back of the metal valve stem while guiding the probe through the wheel, placing the potted part facing the wheel. Set the sensor nut with the washer 3 to the sensor housing part 2 using your hands and then push the sensor housing down to make it flush before tightening it to 8 Nm (71 in. lbs.). Do not torque the sensor nut too tightly, as just a small extra amount of 12 Nm (106 in. lbs.) force might cause the sensor to come off the valve stem. Position the sensor valve on the mounting end of the tire so that it is 280° from the head on a rotating wheel tire changer or 210° clockwise from the mount end of the tool on a rotating tool tire changer, avoiding it touching the lower bead breaker part. Inflate the tires to the pressure outlined in the Tire Inflation Pressure Label and make sure the original style valve stem cap is properly fitted. Secure the tire and wheel assembly on the car, remove the support and then lower the vehicle. Use the TPM-RKE Analyzer, 9936, with the Scan Tool to add the sensor ID to the WCM/SKREEM or let the vehicle travel at over 15 mph (24 km/h) for a minimum of ten minutes after staying still for at least twenty minutes. If a sensor does not cooperate with training, check the available diagnosis information.