JeepParts

My Garage

My Account

Cart

OEM Dodge Ram 3500 Van Universal Joint

U-Joint- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Universal Joints found

Dodge Ram 3500 Van Universal Joints Part Number: 4504575

$56.29 MSRP: $123.00You Save: $66.71 (55%)Ships in 1-2 Business Days

Dodge Ram 3500 Van Universal Joints Part Number: 5014733AB

$59.52 MSRP: $130.00You Save: $70.48 (55%)Ships in 1-3 Business Days

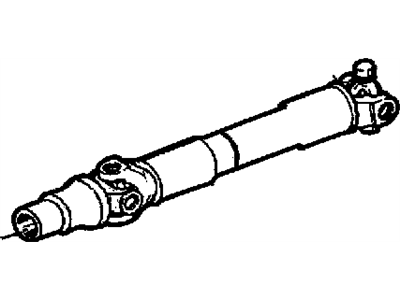

Dodge Ram 3500 Van Universal Joint

Choose OEM Universal Joint that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Universal Joint follows strict manufacturing steps to lock in quality and fit. If your Dodge Ram 3500 Van matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Ram 3500 Van parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

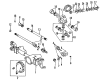

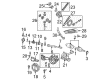

Dodge Ram 3500 Van Universal Joint Parts and Q&A

- Q: How to service and repair a propeller shaft equipped with a Universal Joint in the tube yoke on Dodge Ram 3500 Van?A:Removing the propeller shaft is the first step to fixing or repairing a shaft with a cardan joint in the tube yoke. Use a gentle tap with the drift to remove the snap ring outside the bearing cap and carefully take off the snap rings from the yoke on both sides. Clamp the bearing yoke in a vise or arbor press so that the socket beneath it has room for the cap, with the grease fitting if there is one, pointing toward the top. Further within the yoke, fit a socket with a smaller outer diameter onto the bearing cap and push down to pop off the lower bearing cap. If you can't remove the bearing cap by hand after pressing, hit the yoke ear close to where the cap is to help it out. First, flip the yoke upside down, straighten the cross in the hole and gently press the cross to remove the other bearing cap. Keep the cross or bearing cap correctly positioned during installation so you don't damage the sides of the yoke bore. Start assembly by inserting high-pressure grease of EP N.L.G.I. Grade 1 or 2 into the inside surfaces of the yoke bores. Take the cross and put it in the yoke, making the lube fitting aim up. Follow this by putting a bearing cap over the trunnion which you should align with the bore of the yoke so the needle bearings stay upright. Gently push the bearing cap down into the yoke bore until the snap ring is able to be installed inside it, then put the snap ring into place. Proceed with the bearing cap on the other side and if binding or stiff, give the yoke a few taps with a soft hammer to set the needle bearings. Afterward, add grease to the lube fitting, if you have it and secure the propeller shaft back in place.