JeepParts

My Garage

My Account

Cart

OEM Dodge Ram 3500 Van Drive Shaft

Axle Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Drive Shafts found

Dodge Ram 3500 Van Drive Shaft Part Number: 52105678AC

Dodge Ram 3500 Van Drive Shaft Part Number: 52105412AA

Dodge Ram 3500 Van Drive Shaft Part Number: 52105411AC

Dodge Ram 3500 Van Drive Shaft Part Number: 52105410AA

Dodge Ram 3500 Van Drive Shaft

Choose OEM Drive Shaft that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Drive Shaft follows strict manufacturing steps to lock in quality and fit. If your Dodge Ram 3500 Van matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Ram 3500 Van parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

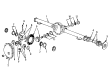

Dodge Ram 3500 Van Drive Shaft Parts and Q&A

- Q: How to service and repair the Drive Shaft on Dodge Ram 3500 Van?A:For servicing and repairing the drive/propeller shaft, position the vehicle level at the axles and let the wheels turn. Before installing the base, take out the external bearing snap rings in the universal joint. Rotate the shaft so that the transmission/transfer case output yoke bearing cap is in the down position, if appropriate and make all your measurements from the front toward the rear. Set the inclinometer on the shaft so it is aligned with the yoke pivot or the pinion ring, on the gear side. Set the bubble in the center to mark the angle of the Transmission or Output Yoke. After that, turn the propeller shaft 90 degrees and place the inclinometer on the yoke bearing cap so it is even with the shaft and align the bubble to find the angle of the shaft. Take away the smaller angle from the larger to find out the operating angle for the gear transmission. Following this, turn the propeller shaft so that the card is perpendicular to its shaft, then lay the inclinometer flat onto the pinion yoke bearing cap, right at the bottom of the bubble to record the pinion shaft or input yoke angle. The axle Input Operating Angle is found by subtracting the smaller from the larger figure. Achieve less than 1 degrees difference in the U-joint operating angles, maintain operating angles not over 3 degrees and try for at least 1/2 of one degree of continuous operating angle for the propeller shaft.

- Q: How to remove and install the Drive Shaft on Dodge Ram 3500 Van?A:Raise the vehicle on safety stands and then shift the transmission into Neutral. Put marks across the axle pinion yoke or companion flange and the propeller shaft or companion yoke to guide installation. When working on Dana axles, take out the bolts that secure the universal joint clamps to the pinion yoke. Take out the bolts that hold the companion yoke to the companion flange for all Corporate axles. First, move the slip yoke from the output shaft of either the transmission or transfer case and then take off the propeller shaft. To install, place the slip yoke onto the end of the transmission or transfer case shaft and make sure that the installation marks on the propeller shaft or companion yoke are aligned with the pinion yoke or companion flange. Carefully place the universal joint into the pinion yoke in Dana axles and tighten the strap bolts until they reach 29 Nm (22 ft. lbs.). Put the companion yoke onto the companion flange and tighten its bolts to 108 Nm (80 ft. lbs.). The last step is to lower the vehicle.