JeepParts

My Garage

My Account

Cart

OEM 2000 Dodge Neon Exhaust Manifold

Engine Exhaust Manifold- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Exhaust Manifolds found

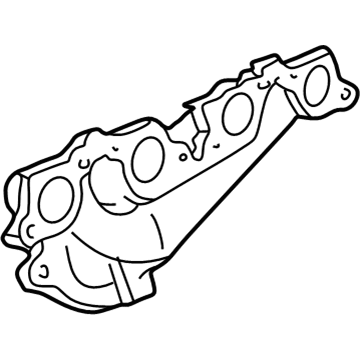

2000 Dodge Neon Exhaust Manifold Part Number: 4777619AC

Product Specifications- Other Name: Manifold - Exhaust; Manifold Exhaust

- Item Weight: 12.90 Pounds

- Item Dimensions: 15.6 x 14.3 x 6.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4777619AC

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2000 Dodge Neon Exhaust Manifold Part Number: 4777904AC

Product Specifications- Other Name: Manifold; Manifold Exhaust

- Item Weight: 19.60 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4777904AC

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2000 Dodge Neon Exhaust Manifold Parts and Q&A

- Q: How to Effectively Service and Repair an Exhaust Manifold on 2000 Dodge Neon?A: To start, unhook the negative cable from the battery and get the vehicle onto a hoist so that it can be raised. Remove the bolt joining the wire harness heat shield to the exhaust manifold support bracket on Federal and LEV models or to the exhaust manifold on ULEV models, followed by removing the exhaust manifold support bracket from Federal and LEV models. First, take out the bolts that hold the exhaust system flex joint to the exhaust manifold and then push the rest of the exhaust backwards so it moves clear of the flange studs. With a car having ULEV, take off the support bracket between the cylinder block and the exhaust manifold. Pull the vehicle down and unplug both the CCV hose and the oxygen sensor harness from the rear of the cylinder head cover. Lift off the heat shield bolts and remove the upper heat shield to access the manifold bolts and when done, remove them too. On ULEV vehicles with a cylinder head, open the cylinder head cover and put a covering over the cylinder before taking off the exhaust manifold from the top of the vehicle, just under the cowl. Installing the manifold, first put the exhaust manifold and gasket in their locations, fasten the exhaust bolts and tighten them in the proper order to 23 Nm (200 inch lbs.). For ULEV-enabled cars, attach the upper heat shield to the exhaust manifold and use the supplied bolts and tighten each to 23 Nm (200 inch lbs.). After that, fix the lower and upper heat shield onto the exhaust manifold, install all the bolts and tighten them to 11 Nm (95 inch lbs.). Attach the electrical connector of the oxygen sensor to its harness and, if your vehicle is ULEV, also add the cylinder head cover. Tie the CCV hose onto the port on the cylinder head cover, lift the vehicle again and put in a new flex joint at the manifold's gasket. Join the exhaust to the manifold flange and fixing screws to 28 Nm (or 250 inch lbs.). On Federal and LEV models, set up the exhaust manifold support bracket, tightening the M10 bolt to 54 Nm (40 ft. lbs.), the M12 bolt to 95 Nm (70 ft. lbs.) and the nut to 28 Nm (250 inch lbs.). For ULEV vehicles with support installed, attach the support bracket to the cylinder block and exhaust manifold, tighten all bolts loosely first, then tighten them again to 54 Nm (40 ft. lbs.). After that, fasten the bolt onto the wire harness heat shield to connect it to the support bracket on Federal and LEV models or to the exhaust manifold on ULEV models.