JeepParts

My Garage

My Account

Cart

OEM 2000 Dodge Ram 1500 Brake Line

Brake Hose- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

9 Brake Lines found

2000 Dodge Ram 1500 Brake Hose Part Number: 52009945AD

$385.83 MSRP: $633.00You Save: $247.17 (40%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Line - Brake; Brake Hydraulic Hose; Hydraulic Hose; Brake Line

- Replaces: 52009945AC

- Item Weight: 1.50 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52009945AD

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2000 Dodge Ram 1500 Flex Hose Part Number: 52009575AE

$218.28 MSRP: $277.00You Save: $58.72 (22%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose - Brake; Hydraulic Hose; Brake Hose; Brake Line

- Replaces: 52009575AC, 52009575AD

- Item Weight: 0.80 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52009575AE

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2000 Dodge Ram 1500 Flex Hose Part Number: 52009689AC

Product Specifications- Other Name: Line - Brake; Hydraulic Hose; Brake Hose; Brake Line; Hose Brake

- Item Weight: 1.90 Pounds

- Item Dimensions: 10.4 x 10.3 x 2.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52009689AC

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2000 Dodge Ram 1500 Flex Hose Part Number: 52009685AC

Product Specifications- Other Name: Line - Brake; Hydraulic Hose; Brake Hose; Brake Line; Hose Brake

- Item Weight: 3.30 Pounds

- Item Dimensions: 5.3 x 3.7 x 1.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52009685AC

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2000 Dodge Ram 1500 Brake Tube Part Number: 52009912AB

Product Specifications- Other Name: Tube Brake; Brake Hose; Brake Line

- Item Weight: 0.90 Pounds

- Item Dimensions: 128.5 x 3.8 x 4.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52009912AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2000 Dodge Ram 1500 Brake Tube Part Number: 52009910AB

Product Specifications- Other Name: Line - Brake; Brake Hose; Brake Line; Tube Brake

- Item Weight: 1.40 Pounds

- Item Dimensions: 109.2 x 6.2 x 4.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52009910AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2000 Dodge Ram 1500 Flex Hose Part Number: 52009845AB

Product Specifications- Other Name: Line; Hydraulic Hose; Brake Hose; Brake Line; Hose Brake

- Item Weight: 0.80 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52009845AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2000 Dodge Ram 1500 Flex Hose Part Number: 52009683AB

Product Specifications- Other Name: Line Brake; Hydraulic Hose; Brake Hose; Brake Line; Hose Brake

- Item Weight: 1.40 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52009683AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2000 Dodge Ram 1500 Flex Hose Part Number: 52009682AB

Product Specifications- Other Name: Line; Hydraulic Hose; Brake Hose; Brake Line; Hose Brake

- Item Weight: 0.90 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52009682AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

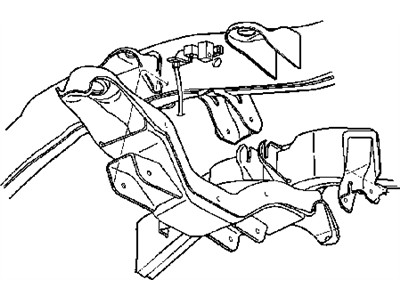

2000 Dodge Ram 1500 Brake Line Parts and Q&A

- Q: What Are the Essential Procedures and Tools for Brake Line Service and Repair on 2000 Dodge Ram 1500?A: The best option for repairing or servicing brake hoses and lines is a metal brake tube, but you may use double-wall steel tube when factory replacements can't be found. To ensure metal brake tubes bend properly, special equipment is needed, as is certain equipment for forming double inverted flares or ISO flares. The first step to double inverted flaring is to remove the bad part with a Tubing Cutter and ream the edges with a suitable tool to make the flare proper. Secure the nut on the replacement tube, attach the tube to the flaring tool and cover the tube's other end with the gauge forming tool. Lay the tubing into the jaws, making sure it touches the appropriate notch in the gauge and then tighten the tool bar down on the tube. Stick the probe from the gauge into the tube, slide the compression rack over the gauge and set the flaring screw in the middle of the compression rack. Once the plug gauge is on the center of the flaring tool jaws, tighten the handle to twist the plug, removing it afterward to finish flaring. To perform ISO flaring, pick the Snap-On Flaring Tool TFM-428 or choose any comparably designed flaring tool. Disconnect the damaged tube at the location of the bulge, remove any rough edges left in the tube opening and assemble a tube nut onto the tube. Ensure the tube is level with the top of the flaring tool in the tool bar and turn the tool to tighten the tube against the bowl. Put the right size adaptor on the flaring tool yoke screw, grease it, place it over the tube and tighten the yoke screw until the adaptor sits straight on the tool bar.