JeepParts

My Garage

My Account

Cart

OEM 2000 Dodge Ram 1500 Intake Manifold

Engine Intake Manifold- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Intake Manifolds found

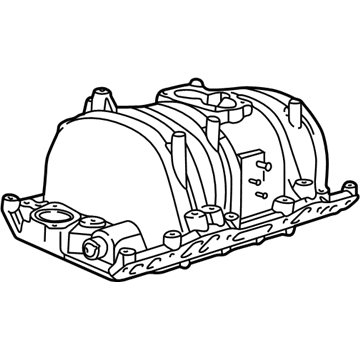

2000 Dodge Ram 1500 Intake Manifold Part Number: 4897489AB

Product Specifications- Other Name: Manifold - Intake; Engine Intake Manifold; Manifold Intake

- Item Weight: 3.20 Pounds

- Item Dimensions: 18.2 x 18.2 x 10.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4897489AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

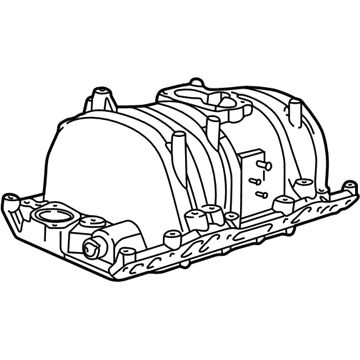

2000 Dodge Ram 1500 Intake Manifold Part Number: 4897490AC

Product Specifications- Other Name: Manifold - Intake; Engine Intake Manifold; Manifold Intake

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4897490AC

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2000 Dodge Ram 1500 Intake Manifold Parts and Q&A

- Q: How to Remove and Install an Intake Manifold on 2000 Dodge Ram 1500?A: Before you remove the intake manifold, take off the negative battery cable and drain the cooling system. After that, take away the A/c compressor, generator, accessory drive bracket and air cleaner. Release the fuel system pressure and then separated the fuel lines. Remove the accelerator, speed control and kickdown cables, if your vehicle has them and remove the return spring as well. Remove the distributor cap, wires, disconnect the coil wires, send the unit wire, together with the heater hoses and bypass hose. First, discard the crankcase ventilation and evaporation control systems and then take out the bolts from the intake manifold. Pull the whole assembly of the intake manifold and throttle body from under the hood, removing and discarding the flange gaskets and two cross-over gaskets. Should you need to, disconnect the throttle body and plenum pan, throwing away the gasket as you go. To install the plenum pan, replace the gasket and clamp down onto bolts with a torque of 5.4 Nm (48 in. lbs.), then tighten to 9.5 Nm (84 in. lbs.) and test by twisting another 9.5 Nm (84 in. lbs.). Lay a new gasket on the throttle body, install it on the intake manifold and put a 5 mm (0.2 in) diameter bead of Mopar Gen Ii Silicone Rubber Adhesive Sealant on each of the four corners. Install the front and rear cross-over gaskets and then the flange gaskets, checking the alignment at the cylinder head-gasket tabs and making certain that both flange gaskets have Manifold Side showing. Fix the intake manifold onto the cylinder block and heads, through the use of the alignment dowels in the crossover gaskets. After the seals, put in the intake manifold bolts and tighten them correctly. Return the crankcase ventilation and evaporation control systems to the engine, connect the coil wires and add the heat indicator send unit cable, all the hoses and bypass tube. Attach the distributor cap and wires, insert the return spring and link up the accelerator linkage together with the speed control and transmission kickdown cables if present. Farmola engineers recommend tightening the generator mounting bolt at 41 Nm (30 ft. lbs.). At this point, put the air cleaner in, add the fluids to the cooling system and attach the negative cable to the battery.