JeepParts

My Garage

My Account

Cart

OEM 2001 Dodge Ram 3500 Intake Manifold

Engine Intake Manifold- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Intake Manifolds found

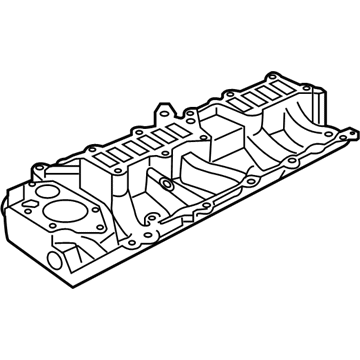

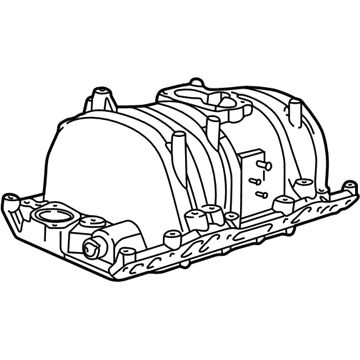

2001 Dodge Ram 3500 Intake Manifold Part Number: 53031583

Product Specifications- Other Name: Manifold - Intake; Manifold Intake

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 53031583

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

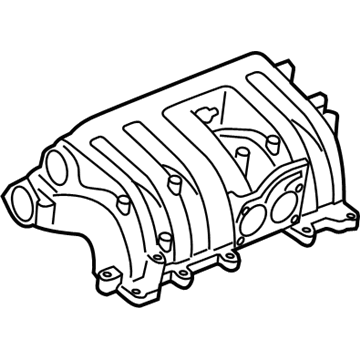

2001 Dodge Ram 3500 Intake Manifold, Upper Part Number: 53031580

Product Specifications- Other Name: Manifold - Intake; Engine Intake Manifold, Lower, Upper; Manifold Intake

- Position: Upper

- Item Weight: 29.00 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 53031580

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2001 Dodge Ram 3500 Intake Manifold Part Number: 4897490AC

Product Specifications- Other Name: Manifold - Intake; Engine Intake Manifold; Manifold Intake

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4897490AC

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2001 Dodge Ram 3500 Intake Manifold Parts and Q&A

- Q: How to Remove and Install an Intake Manifold on 2001 Dodge Ram 3500?A: Start by removing the negative battery cable before you drain the internal cooling system to take out the intake manifold. After that, remove the compressor, generator, brackets for the drive and the air cleaner. Release the Fuel System Pressure and disconnect all the fuel lines. If those cables are installed, remove them and the storage spring before continuing. Open the distributor cap and unscrew the wires, take the coil wires off, disconnect the heat indicator sending unit wire and release all the heater hoses with the bypass hose. Take off the crankcase ventilation system and the evaporation control system after that, as well as the bolts securing the intake manifold. Together, lift the intake manifold and throttle body out of the engine compartment and throw away the gaskets and seals from the flange side as well as from the front and back. Relieve the throttle body by removing its bolts and pulling it off the manifold without keeping the gasket. Should it be wanted, take off the plenum pan and gasket, but throw the gasket away. Next, set the plenum gasket into its groove and install the plenum to its standoff location, tightening all the bolts to 5.4 Nm (48 in. lbs) first, then check to see that everything is tightened at 9.5 Nm (84 in. lbs). Attach flange gaskets, so that the tab for vertical alignment moves onto the block's deck face and the horizontal alignment tabs line up with those from the cylinder head gasket, making sure you see the words Manifold Side on each flange gasket. Put a drop of Mopar Gen Ii Silicone Rubber Adhesive Sealant, the same size and length, at each of the cabin's four corners. Put in the front and rear seals, making sure the molded dowel pins enter the matching holes in the block of the cylinder. Lower the intake manifold so that it is in the correct spot on the cylinder block and heads and check the seals as you do so. Take a new gasket, put the throttle body on the intake manifold and tighten the bolts until they reach 23 Nm (200 in. lbs.). Complete the installation of the intake manifold bolts, tightening bolts 1 through 4 then 5 through 12, alternately by 1.4 Nm (12 in. lbs.) at a time, to 8 Nm (72 in. lbs). Then parallel-check all the bolts' torque for 8 Nm (72 in. lbs.) and finally tighten each bolt by 0.8 Nm (7 in. lbs.) to 16 Nm (12 ft. lbs.). Replace the closed crankcase ventilation and evaporation control, put in the coil wires and reconnect other hoses: the heat indicator sending unit wire, heater hoses and bypass hose. We must install the distributor cap and wires, hook up the return spring and link up the accelerator linkage, speed control and transmission kickdown cables if we have them. Put in the fuel lines, accessory drive bracket and A/C compressor and after that, attach the generator and belt. Next, fasten the generator mounting bolt to 41 Nm (30 ft. lbs.) torque. After that, connect the air cleaner, add the cooling system fluid and link the negative battery cable again.