JeepParts

My Garage

My Account

Cart

OEM Dodge Ram 3500 Intake Manifold

Engine Intake Manifold- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Intake Manifolds found

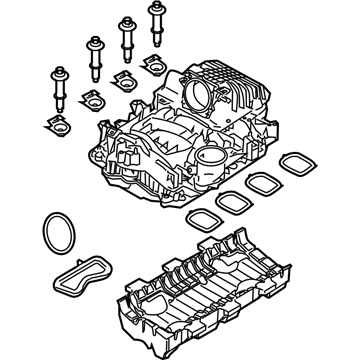

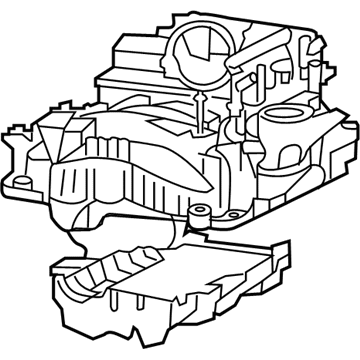

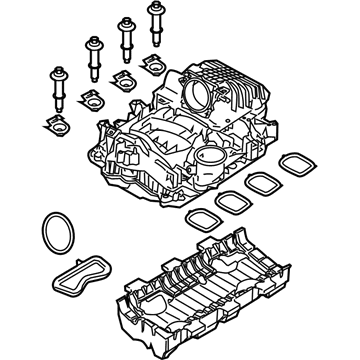

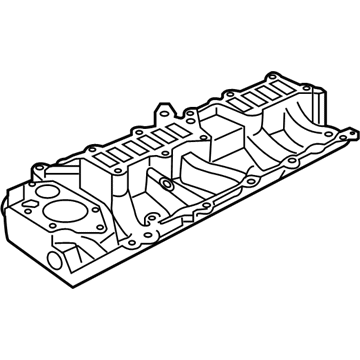

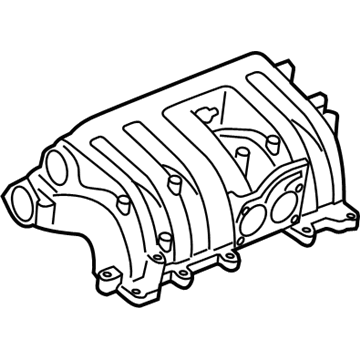

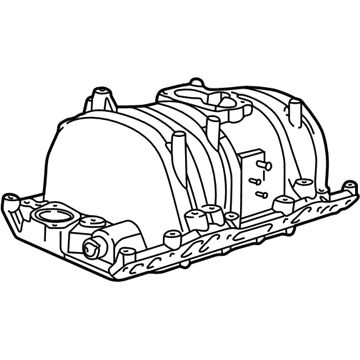

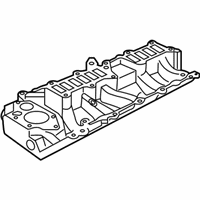

Dodge Ram 3500 Intake Manifold Part Number: 5127193AF

Dodge Ram 3500 Intake Manifold Part Number: 5101945AB

Dodge Ram 3500 Intake Manifold Part Number: 68194114AC

$919.44 MSRP: $1340.00You Save: $420.56 (32%)

Dodge Ram 3500 Intake Manifold Part Number: 5175896AB

$716.77 MSRP: $1050.00You Save: $333.23 (32%)Dodge Ram 3500 Intake Manifold Part Number: 53031583

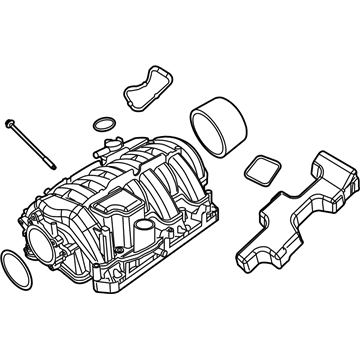

Dodge Ram 3500 Intake Manifold, Upper Part Number: 53031580

Dodge Ram 3500 Intake Manifold Part Number: 4897490AC

Dodge Ram 3500 Intake Manifold Part Number: 4897490AB

Dodge Ram 3500 Intake Manifold

Choose OEM Intake Manifold that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Intake Manifold follows strict manufacturing steps to lock in quality and fit. If your Dodge Ram 3500 matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Ram 3500 parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

The Intake Manifold of Dodge Ram 3500 vehicles help to supply the required air and fuel to the engine cylinder and hence the name intake manifold. This include a number of tubes that channel the air from the air filter through the throttle body as well as housing temperature, airflow and pressure sensors. Early systems for the Dodge Ram 3500 intake manifold were forged from aluminum or cast iron, however, the modern production employs composites from plastic. Some Dodge Ram 3500 vehicles can include the introduction of variable-length intake manifolds which increases power, torque and fuel economy because they change the length of the intake manifold. This technology get the premier airflow using the Venturi effect and resonance of Helmholtz under various loads of the engine. In general, the construction of the intake manifold used in the Dodge Ram 3500 and materials used are critical in maintaining the efficiency and power of the engine with a consideration of problems such as those that affect airflow, for instance, breakdowns in gaskets or hoses.

Dodge Ram 3500 Intake Manifold Parts and Q&A

- Q: How to Remove and Replace an Intake Manifold on Dodge Ram 3500?A:Before removing and putting in the intake manifold, remove the negative cable from the battery. Remove the resonator assembly and air inlet hose after that. Take off the Manifold Absolute Pressure (MAP) Sensor, Intake Air Temperature (IAT) Sensor, Throttle Position (TPS) Sensor and Coolant Temperature (CTS) Sensor. Also, unplug the brake booster hose and the positive crankcase ventilation (PCV) hose. You should take the generator out of the A/C Compressor and set it aside, but you don't need to remove any Freon or connections from the compressor. Take out the air conditioning compressor and place it away from the system. Flush the fuel system, next loosen the intake manifold fasteners in a zigzag order. Unscrew those on the outer side and then those on the middle. Once you've finished, remove the intake manifold and IAFM as a unit.

- Q: How to Service an Intake Manifold on Dodge Ram 3500?A:The first step is to disconnect the negative cables from the battery. Remove the charge air cooler outlet tube and remove the engine oil dipstick tube mounting bolt from the inlet housing. Then, take out the dipstick support from the fuel filter housing and place the dipstick tube to the side. Remove the power cables from the air grid heater at the cable studs and unhook the ground strap at the intake cover. To start, take out the engine wiring harness connections at the air inlet housing elbow and then remove the air inlet housing's four mounting bolts so that the housing is no longer attached to the heater elements. Remove the intake air grid heater assembly from the manifold, remove the high pressure fuel lines and remove the Fuel Rail next. Release the APPS bracket from the cylinder head to gain access to the cover bolts of the front intake manifold and after that detach the connector for the manifold air temperature/pressure sensor. Raise the remaining bolts from the intake manifold cover-to-cylinder head, then remove the cover and keep it away from the air intake. Wipe the intake manifold cover and cylinder head sealing surface clean and clean the intake manifold with solvent before blowing it dry. Apply a suitable solvent on the cylinder block gasket to only clean it, then be sure the plenum pan rail is clean and completely dry. Make sure the manifold does not have any cracks and use a straightedge to see if the mating surfaces are flat. Once you have a new gasket, follow it with the installation of the intake manifold cover, then install the bolts that do not support the fuel rail, fastening them to 24 Nm (18 ft. lbs.) torque. Attach the high pressure rail and the fuel lines, then use two fresh gaskets to set up the intake air grid heater and air inlet housing and tighten the screws to 24 Nm (18 ft. lbs.) using a torque wrench. Join the many-sensor air temperature/pressure connector, tighten the air intake bracket's fasteners to 120 in. lbs. (14 Nm) and connect the APPS bracket, tightening its fasteners to about 32 ft. lbs. (43 Nm). After the support is back in place, slide the engine oil dipstick tube and bolt into the housing. After placing the outlet tube from the charge air cooler onto the air inlet housing, tighten it with 8 Nm or 72 in. lbs. of torque. Tie the engine wire harness to the air inlet housing in two different places, prime the fuel and link the negative Battery Cables again.