JeepParts

My Garage

My Account

Cart

OEM 2002 Chrysler 300M Brake Caliper

Caliper- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Brake Calipers found

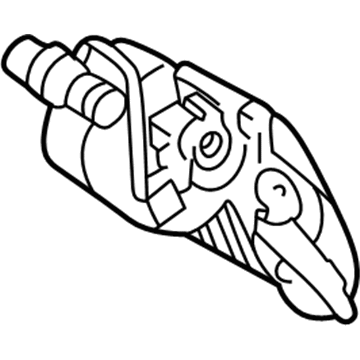

- Product Specifications

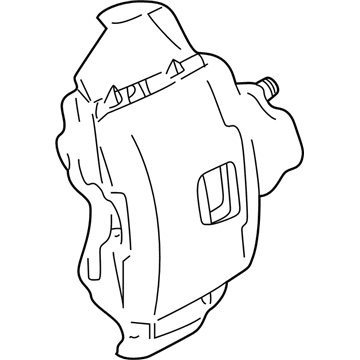

- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Rear Right; Brake Caliper; Caliper

- Position: Rear Passenger Side

- Item Weight: 4.40 Pounds

- Item Dimensions: 8.9 x 6.5 x 5.7 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5011746AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

- Product Specifications

- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Rear Left; Brake Caliper; Caliper

- Position: Rear Driver Side

- Item Weight: 4.10 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5011747AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

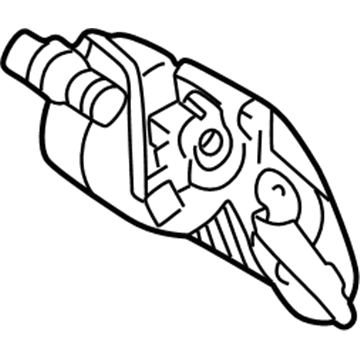

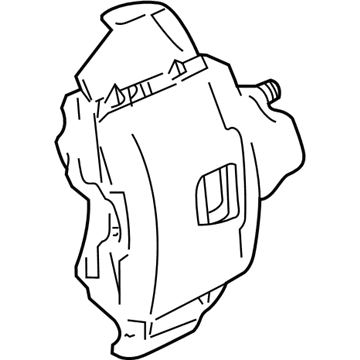

- Product Specifications

- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Front Right; Caliper; Caliper Disc Brake; Brake Caliper

- Position: Front Passenger Side

- Item Weight: 7.70 Pounds

- Item Dimensions: 8.7 x 7.1 x 5.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5010032AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

- Product Specifications

- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Front Left; Caliper; Caliper Disc Brake; Brake Caliper

- Position: Front Driver Side

- Item Weight: 7.80 Pounds

- Item Dimensions: 8.3 x 6.7 x 5.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5010033AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2002 Chrysler 300M Brake Caliper Parts and Q&A

- Q: How to Service and Repair a Brake Caliper on Rear Disc Brakes on 2002 Chrysler 300M?A: You should first clean and check the caliper before you disassemble it for service or repair. After taking the caliper off the brake rotor, hang it on a wire hook to safe guard the brake rotor and the vehicle's body from getting exposed to brake fluid. Pull off the brake shoes and insert a bit of wood on the caliper between the fingers and the piston. Very gently press the brake pedal to force the piston through the bore and hold it down to make sure fluid doesn't drain. Remove the brake fluid flex hose nonviolently after taking it out of the caliper on the vehicle. Grip the caliper with safety jaws in a vise and remove the piston boot, clean and throw away. After that, extract the piston seal from its groove using a soft tool and discard the old seal, too. Soak cotton swabs in alcohol or a suitable solvent and wipe everything down, letting it dry with a cloth that has no lint. Check the condition of the piston bore for any visible scratching or pits; if they are only light, buff them with a crocus cloth, but for more serious scratches, hone the bore with a Caliper Hone, Special Tool C-4095 or an equivalent, stopping if the bore diameter increases by up to 0.001 inch (0.0254 mm). Should the bore continue to fall outside this specification, put in a new caliper housing. While honing, drench the stones and bore with brake fluid, after honing clean the grooves and seals with a rotary brush and don't forget to flush the caliper bore with fresh brake fluid and wipe it dry. Examine the caliper piston by hand or with a magnifying glass and if you notice pitting, scratches or damage, swap it out. Before wiping, moisten brake components and then wipe with a wet cloth, safely throwing away anything with asbestos fibers in a sealed container. Preventively treating the inside of the brake caliper can be done with extra, new brake fluid or Mopar Non-Chlorinated Brake Parts Cleaner instead of gasoline, kerosene, alcohol, oil or transmission fluid. See if there are leaks, dust boot damage or any issues with the guide pin dust boots on the caliper; if you do, disassemble and recondition the caliper and replace seals and dust boots as needed. Fold the guide pin bushing in half and then push it into the caliper mounting boss; extend it again until the first and second ends are all the way in. Lubricate inside of the bushing with Mopar Dielectric Grease or a similar product and then insert the guide pin sleeve into one of the bushing's holes. Slot the boots into the end of the steel sleeve until the seal groove receives the boot on both sides. After pure brake fluid is put on a new piston seal, place it in the groove of the caliper bore and snugly mount it with your fingers during insertion. Soak the new piston boot in clean brake fluid and then put it over the piston. Use the same amount of force all around the piston as you put it into the bore to keep it from cocking and binding. Secure the piston inside the caliper bore, so it rests all the way down and place the dust boot inside the piston bore's counterbore. Attach a hammer and the Installer, Special Tool C-4689 or C-4842 and the handle, Special Tool C-4171, to press the boot into the counterbore. After that, attach the caliper back on the vehicle and bleed the brakes when it's necessary.