JeepParts

My Garage

My Account

Cart

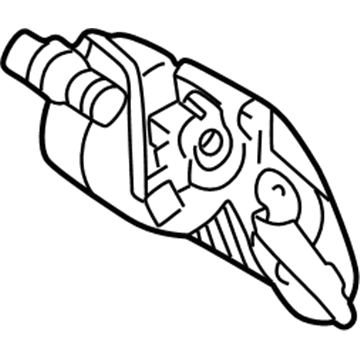

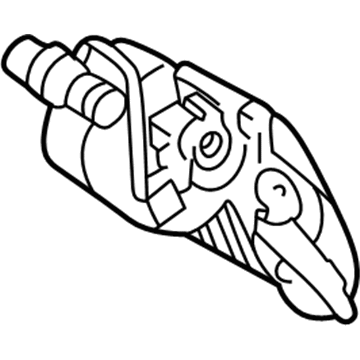

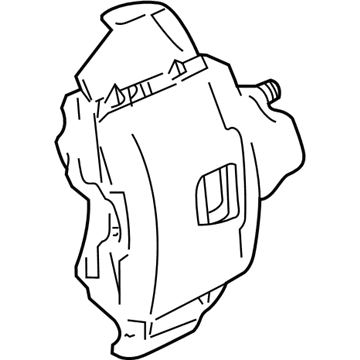

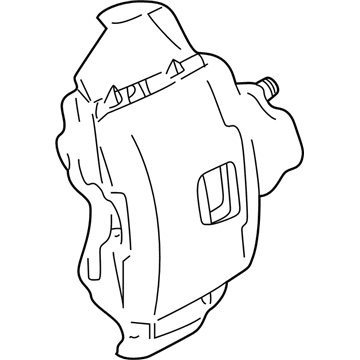

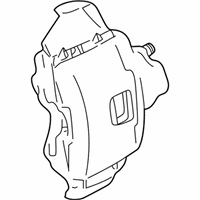

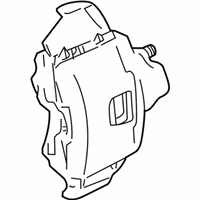

OEM Chrysler 300M Brake Caliper

Caliper- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Brake Calipers found

Chrysler 300M Brake Caliper

Choose OEM Brake Caliper that meet Chrysler factory standards. Chrysler designs and tests every component for precision and durability. Each Brake Caliper follows strict manufacturing steps to lock in quality and fit. If your Chrysler 300M matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine 300M parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

The Chrysler 300M Brake Caliper is a vital part of the braking system; therefore, calipers are well known for their reliability and power in different models of the 300M car. This particular Brake Caliper translates hydraulic pressure created from the master cylinder into mechanical force to make sure that the brake pads apply adequate force on the rotors to cease or slow down the operations of the vehicle. Depending on the type and model, Chrysler 300M vehicles may have fixed and floating calipers, fixed calipers apply pressure through multiple pistons and the floating ones contain one that slides. Chrysler 300M Brake Caliper assembly generally consists of strong material such as cast iron used for the body and steel or phenolic for the pistons to increase the life span and reliability of the Caliper. It is also important to have frequent check up and servicing of the Brake Caliper in order to avoid calamities like; uneven pads wear or brake drag which is dangerous. Although it belong to the automotive parts it is unique in the market with advanced features such as options for performance enhancing that increases the staking power as well as aesthetic enhancements to the Chrysler 300M Brake Caliper. This Brake Caliper is not only that helps the Chrysler 300M's performance but also has a big responsibility on safety for the driver and passengers. The Chrysler 300M brake caliper is also versatile for most 300M models thus proving Chrysler's reliability and innovations in the production of cars.

Chrysler 300M Brake Caliper Parts and Q&A

- Q: How to Effectively Disassemble and Recondition a Brake Caliper on Chrysler 300M?A:Before taking the brake caliper apart, clean and examine it. Pull the guide pin bushing sleeve aside, moving it closer to the back end of the caliper, as you withdraw it out of both parts. Lift one side of the rubber bushing and swing it out of the quill located in the brake caliper mounting boss. Pressure from the vehicle's brake system will help you take the Piston out of the caliper bore. Take the caliper from the brake rotor and suspend it away from the rotor and car body on a wire hook to stop brake fluid from coming into contact. Remove the brake shoes and then set a small bit of wood between the piston and caliper fingers. Press the brake pedal all the way down to force fluid into the piston. After that, use a special holding tool to make sure the brake pedal doesn't move an extra inch so the fluid doesn't drain out of the reservoir. Connect a clamp on the bigger side of the flex hose and disconnect it from the caliper, then take it out of the car, always be sure to tighten the caliper very gently since force could distort the bore. Hold the caliper in a vise with protective jaws, take out and toss the piston dust boot and push the piston seal out of the caliper piston bore with a soft, plastic trim stick, also getting rid of the old seal. With alcohol or a similar solvent, clean the bore and all the inner passages, then remove any remaining liquid with a lint-free cloth. If the piston bore has light scratches or corrosion, you can buff them with crocus cloth; for deep scratches, you need to hone the bore with Caliper Hone, Special Tool C-4095 or the same type using a sanding tool, so long as it increases the bore diameter by no more than 0.0254 mm (0.001 inch). If the bores do not reach the required measure, you need to fit a new caliper housing. When honing, brush brake fluid onto the stones and bore and then after honing, wipe the seal and grooves with a non-metallic brush, flush the caliper bore with fresh brake fluid and dry it with a clean cloth. Keeping an eye out for pitting, scratches or any other damage, replace the piston if you see it on the caliper. The best way to clear out the brake caliper passages is to use fresh brake fluid or Mopar Non-Chlorinated Brake Parts Cleaner rather than gasoline, kerosene, alcohol, oil, transmission fluid or any liquid that carries mineral oil. Check the brake caliper closely for signs of brake fluid leaks, breaks, becoming brittle or damage to the boots around the pistons and guide pins; if it fails inspection, open it up and clean or replace the needed parts. For assembly, bend the guide pin bushing in half down the middle and then push it in place into the caliper boss with your hands. Unroll the bushing inside the caliper's housing so that the flanges rest level on each side of the hole. Coat the insides of the bushing with Mopar Dielectric Grease or a similar product and then fasten the guide pin sleeve into one side so that the seal zone goes past the groove associated with the sleeve. Insert the steel sleeve through the bushing so that the boot at the end of the sleeve fits into the seal groove and then add the groove in the other bushing onto that end of the sleeve. Make sure the bushing fits tightly at both ends where the grooves are. Dip the seals in brake fluid, then put one in each caliper groove and work it around using your fingers. Coat the boot with brake fluid and leave some inside it before putting the dust boot onto the piston. Push the piston steadily into the caliper bore using the same force, moving it past the seal and making sure it's all the way in. Drop the dust boot onto the counterbore of the caliper assembly piston bore and push it in the rest of the way by hand or, if necessary, use the hammer and Installer, Special Tool C-4689 or C-4842, along with Handle, Special Tool C-4171. When finished, fit the rebuilt caliper onto the vehicle and tie it down with wires.

- Q: How to Assess and Repair a Front Disc Brake Caliper on Chrysler 300M?A:Remove the front Brake Pads by first getting rid of the wheel wheel, tire assembly and calipers. Take the thickness of wearing parts right after replacement. If, at some point, the measurement falls below 6.5 mm (a quarter inch), the brakes should be serviced. If you are servicing one brake shoe assembly, the other one also must be changed. When there is no need to replace, simply put the assemblies back where they came from. When checking the calipers, watch out for leaks under the boot and within the inboard dust lining and look for any breaks, cracking or damage to the Piston dust boot. Should the boot be damaged or you notice leaking fluid, disassemble the caliper to seal and replace the old boot, seals and piston, if it is scored. Next, look at the dust boots on the guide pins and change them if they become damaged, dry, brittle.