JeepParts

My Garage

My Account

Cart

OEM 2003 Dodge Intrepid Engine Mount

Engine Motor Mount- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Engine Mounts found

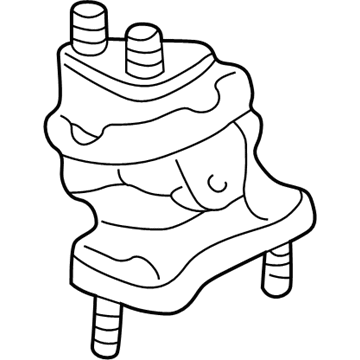

2003 Dodge Intrepid Front Mount, Driver Side Part Number: 4593287AB

$27.86 MSRP: $160.00You Save: $132.14 (83%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Support - Engine Support; Engine Mount, Left; Engine Mount Torque Strut; Engine Mount Bracket; Motor Mount; Front Insulator; Mount

- Position: Driver Side

- Item Weight: 4.70 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4593287AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

Product Specifications

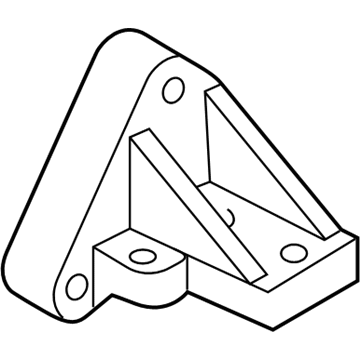

Product Specifications- Other Name: Bracket - Engine Mount; Engine Mount Bracket, Right; Engine Mount Torque Strut; Motor Mount; Mount Bracket; Bracket Engine Mount; Engine Mount Bracket

- Position: Passenger Side

- Item Weight: 2.20 Pounds

- Item Dimensions: 10.3 x 10.6 x 10.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4593182

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2003 Dodge Intrepid Front Mount, Passenger Side Part Number: 4593184AB

Product Specifications- Other Name: Support - Engine Support; Engine Mount, Front, Front Right, Right; Engine Mount Bracket; Motor Mount; Mount

- Position: Passenger Side

- Item Weight: 5.30 Pounds

- Item Dimensions: 5.4 x 4.5 x 4.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4593184AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2003 Dodge Intrepid Front Mount, Driver Side Part Number: 4593285AB

Product Specifications- Other Name: Support - Engine Support; Engine Mount, Front, Front Left, Left; Engine Mount Bracket; Motor Mount; Mount

- Position: Driver Side

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4593285AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2003 Dodge Intrepid Mounting Bracket, Driver Side Part Number: 4593245

Product Specifications- Other Name: Bracket - Engine Mount; Engine Mount Bracket, Left; Engine Mount Torque Strut; Motor Mount; Mount Bracket; Bracket Engine Mount; Engine Mount Bracket

- Position: Driver Side

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4593245

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

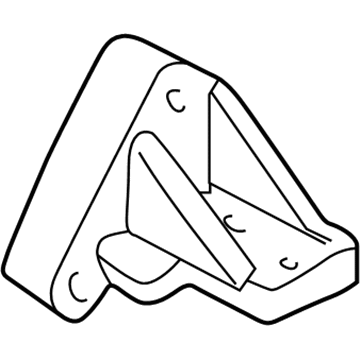

2003 Dodge Intrepid Mount Bracket, Passenger Side Part Number: 4593244

Product Specifications- Other Name: Bracket - Engine Mount; Engine Mount Bracket, Right; Engine Mount Torque Strut; Motor Mount; Front Bracket; Bracket Engine Mount; Engine Mount Bracket

- Position: Passenger Side

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4593244

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2003 Dodge Intrepid Mount Bracket, Driver Side Part Number: 4593243

Product Specifications- Other Name: Bracket - Engine Mount; Engine Mount Bracket, Left; Engine Mount Torque Strut; Motor Mount; Front Bracket; Bracket Engine Mount; Engine Mount Bracket

- Position: Driver Side

- Item Weight: 1.40 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4593243

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2003 Dodge Intrepid Engine Mount Parts and Q&A

- Q: How to Service and Repair a Rear Engine Mount on 2003 Dodge Intrepid?A: To service the rear engine mount, raise the vehicle and support the transaxle. Remove the isolator nuts and rear mount isolator bolts, then take out the mount. For installation, attach the isolator to the crossmember, tighten bolts to 33 Nm, lower the transaxle, and tighten isolator nuts to 61 Nm.