JeepParts

My Garage

My Account

Cart

OEM 2004 Jeep Grand Cherokee Rod Bearing

Engine Connecting Rod Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Rod Bearings found

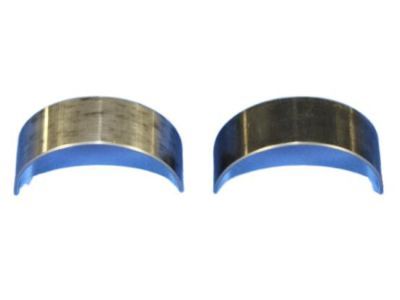

2004 Jeep Grand Cherokee Bearings Part Number: 5012363AE

$16.87 MSRP: $25.00You Save: $8.13 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bearing - Connecting Rod; Rod Bearing; Bearing Kit Connecting Rod Standard See Note; Bearing Kit Connecting Rod Standard

- Replaces: 5012363AC, 5012363AD, 5018584AB, 5012363AB

- Item Weight: 0.50 Pounds

- Item Dimensions: 4.0 x 2.7 x 2.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5012363AE

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

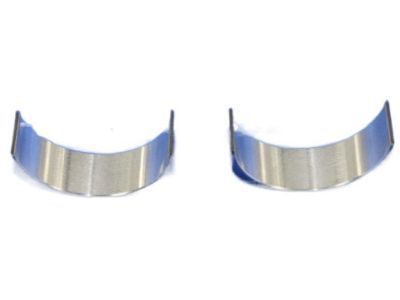

2004 Jeep Grand Cherokee Rod Bearings Part Number: 83500300AC

$17.36 MSRP: $22.95You Save: $5.59 (25%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bearing Kit - Connecting Rod; Bearings; Bearing Kit Connecting Rod Standard

- Replaces: 83500300, 83500300AB, 53020261AC

- Item Weight: 0.50 Pounds

- Item Dimensions: 3.1 x 2.7 x 1.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 83500300AC

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2004 Jeep Grand Cherokee Rod Bearing Parts and Q&A

- Q: What Are the Key Steps to Inspect and Install Rod Bearings on 2004 Jeep Grand Cherokee?A: Examine the rod bearings to find any scoring or damage to the alignment tabs and look for normal signs of wear along with scoring, grooving, fatigue and pitting. If a bearing looks worn out, change it. Search all the connecting rod journals for marks of scoring, minor nicks and burrs, because bent or misaligned connecting rods can often result in abnormal wear on pistons, piston rings, cylinder walls, connecting rod bearings and crankshaft connecting rod journals. When wear spots or other damage are signs of misaligned connecting rods, check each rod for correct alignment and change any rods that are bent or twisted. Rub the oil off the rod journal where it attaches, then use a short rubber hose section over each rod bolt as you install them. First, lubricate the bearing insert at the top and then insert it into the connecting rod. Put in the rod and piston sets with a piston ring compressor, so the oil squirt holes in the rods are next to the camshaft and the arrow on the piston crown is pointing toward the front of the engine. Fit the lower bearing insert into the bearing cap, making sure it is dry, then set a piece of Plastigage on the insert's full width at the center of the cap. Screw the bearing cap and connecting rod into the journal, tightening the nuts to 45 Nm (33 ft. lbs.) still without rotating the crankshaft. Remove the bearing cap and find out how wide the Plastigage measures after being pressed, since the clearance should be the same throughout the entire bearing insert. Once the Plastigage is removed and the clearance is good, proceed to installation; if the clearance is too high, use two 0.0254 mm (0.001 in.) undersized bearing inserts, with all odd size inserts at the bottom. Take another measurement to determine if you should order more undersize inserts. For example, if the clearance is 0.0762 mm (0.003 in.) and you had 0.025 mm (0.001 in.) undersize inserts, the clearance would be reduced to 0.002 inch, making it meet the specification. Measure Plastigage one more time to confirm your bearing choice before final assembly. Then install the proper insert, the cap and fasten the connecting rod bolts to 45 Nm (33 ft. lbs.). To measure the side clearance, place a fit tube between the connecting rod and journal flange on the crankshaft; swap the connecting rod if the clearance is out of specification.