JeepParts

My Garage

My Account

Cart

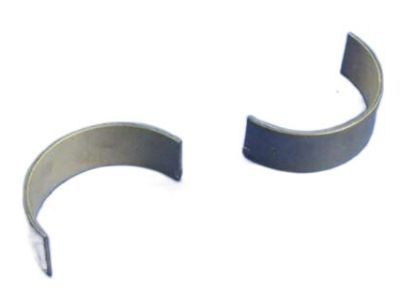

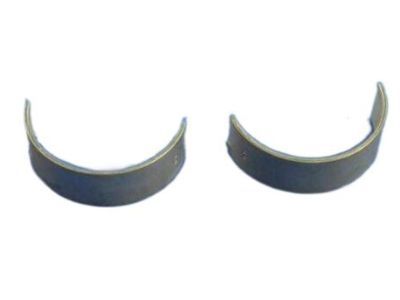

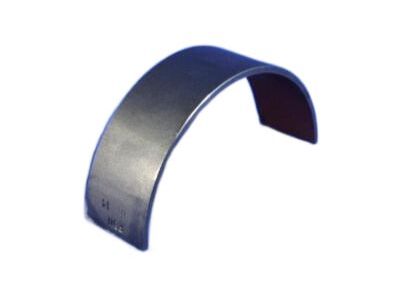

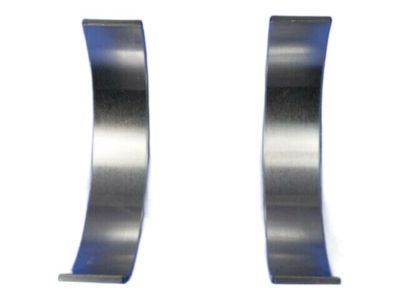

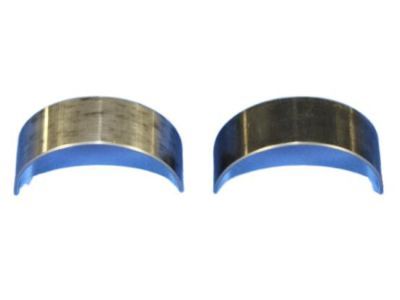

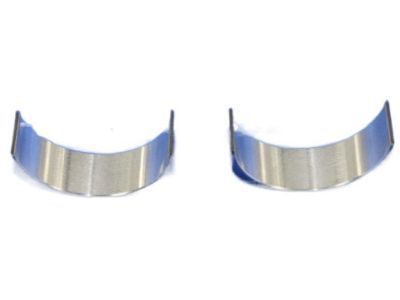

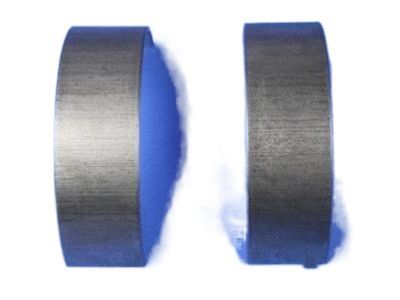

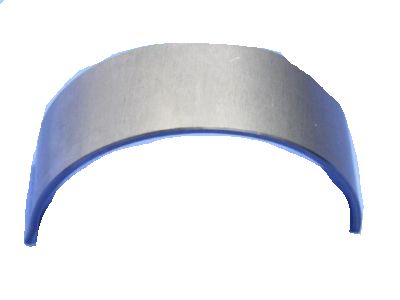

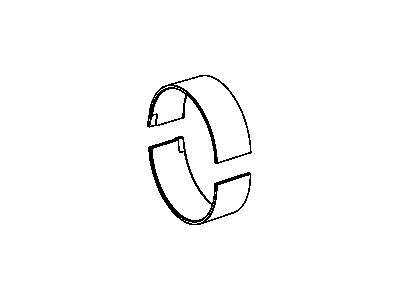

OEM Jeep Grand Cherokee Rod Bearing

Engine Connecting Rod Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

20 Rod Bearings found

Jeep Grand Cherokee Connecting Rod Bearing Part Number: 5184111AF

$3.76 MSRP: $5.65You Save: $1.89 (34%)Ships in 1-2 Business Days

Jeep Grand Cherokee Connecting Rod Bearing Part Number: 68207790AA

$6.32 MSRP: $7.70You Save: $1.38 (18%)

Jeep Grand Cherokee Connecting Rod Bearing Part Number: 4893951AA

$10.38 MSRP: $15.05You Save: $4.67 (32%)Ships in 1-2 Business Days

Jeep Grand Cherokee Bearings Part Number: 68052222AB

$18.13 MSRP: $26.80You Save: $8.67 (33%)Ships in 1-2 Business Days

Jeep Grand Cherokee Bearings Part Number: 5012363AE

$16.87 MSRP: $25.00You Save: $8.13 (33%)Ships in 1-2 Business Days

Jeep Grand Cherokee Connecting Rod Bearing Part Number: 68362046AA

$16.59 MSRP: $24.55You Save: $7.96 (33%)Ships in 1-2 Business Days

Jeep Grand Cherokee Connecting Rod Bearing Part Number: 5184113AF

$3.83 MSRP: $5.65You Save: $1.82 (33%)Ships in 1-2 Business Days

Jeep Grand Cherokee Rod Bearings Part Number: 2421305

$17.58 MSRP: $22.29You Save: $4.71 (22%)Ships in 1-2 Business Days

Jeep Grand Cherokee Connecting Rod Bearing Part Number: 4893953AA

$9.41 MSRP: $13.95You Save: $4.54 (33%)Ships in 1-2 Business Days

Jeep Grand Cherokee Connecting Rod Bearing Part Number: 68029429AC

$16.02 MSRP: $23.55You Save: $7.53 (32%)Ships in 1-2 Business Days

Jeep Grand Cherokee Connecting Rod Bearing Part Number: 4893952AA

$10.56 MSRP: $15.40You Save: $4.84 (32%)Ships in 1-3 Business DaysJeep Grand Cherokee Bearing - Connecting Rod Part Number: 4893538AB

$7.75 MSRP: $11.55You Save: $3.80 (33%)Ships in 1-2 Business DaysJeep Grand Cherokee Connecting Rod Bearing, Green Part Number: 4893539AA

$5.42 MSRP: $7.95You Save: $2.53 (32%)Jeep Grand Cherokee Bearings Part Number: 68047187AB

$38.38 MSRP: $77.85You Save: $39.47 (51%)Ships in 1-2 Business DaysJeep Grand Cherokee Rod Bearings Part Number: 83500300AC

$17.36 MSRP: $22.95You Save: $5.59 (25%)Ships in 1-2 Business Days

Jeep Grand Cherokee Bearing, Yellow Part Number: 68229247AA

$27.84 MSRP: $40.05You Save: $12.21 (31%)

Jeep Grand Cherokee Bearing, Blue Part Number: 68229246AA

$29.52 MSRP: $42.60You Save: $13.08 (31%)

Jeep Grand Cherokee Bearing, Red Part Number: 68229245AA

$37.00 MSRP: $53.50You Save: $16.50 (31%)

Jeep Grand Cherokee Connecting Rod Bearing Part Number: 5184112AF

$16.30 MSRP: $23.55You Save: $7.25 (31%)Jeep Grand Cherokee Connecting Rod Bearing, Red Part Number: 4893537AB

$7.89 MSRP: $11.55You Save: $3.66 (32%)

Jeep Grand Cherokee Rod Bearing

Choose OEM Rod Bearing that meet Jeep factory standards. Jeep designs and tests every component for precision and durability. Each Rod Bearing follows strict manufacturing steps to lock in quality and fit. If your Jeep Grand Cherokee matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Grand Cherokee parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

The Jeep Grand Cherokee Rod Bearing is one of the amazing pieces of machinery that has been greatly improved and boost the reliability of the whole Jeep Grand Cherokee series. The Rod Bearing is positioned to take the load of the engines connecting rods; it acts as the means of rotation and is very sensitive to friction, which if not minimized can lead to major problems affecting the engine's performance and durability. Through the years, different Jeep Grand Cherokee generations have required different Rod Bearings, corresponding to the developments of the engines used ranging from the 4.0 L I6 engine to the modern V8 engines offering up to 475 hp. This evolution is fully coherent with the capabilities of the Rod Bearing to satisfactorily answer to the requirements of each different engine kind, that in turn aids the sturdiness and efficiency of the Grand Cherokee production at large. Highly acclaimed for its handling and safety, the Jeep Grand Cherokee's unibody contributes to the vehicle's overall structure and the improvement of fuel economy and stability; the Rod Bearing also strengthens the necessary performance of the Jeep's engine in accord with driving conditions. Moreover, the Jeep Rod Bearing is greatly fortified for out of door usage as it is applied on Jeep Grand Cherokee and thus is unique in the automotive marketplace. The willingness which is exhibited propels the importance of the part because of its versatility in terms of serving various trims, and even different engines for the Grand Cherokee lineup. In conclusion, the Jeep Grand Cherokee Rod Bearing is not a mere part; it is a symbol of the Jeep's brazen passion on handling luxury SUV category with appreciation and distinctiveness.

Jeep Grand Cherokee Rod Bearing Parts and Q&A

- Q: How to Inspect and Replace Rod Bearings to Ensure Proper Alignment and Clearance on Jeep Grand Cherokee?A:Examine the connecting rod bearings to determine any scoring and check normal wear patterns, scoring, grooving, fatigue, and pitting and remove a bearing that has abnormal wear. Look at the connecting rod journals in case of scoring, nicks and burrs, Owing to misaligned or bent connecting rods, abnormal wear may occur on Pistons, piston rings, and cylinder walls, and also the connecting rod bearings and the Crankshaft connecting rod journals. Look to see that wear patterns or damages reveal misaligned connecting rod and adjust it correctly or replace any misaligned, bent, or twisted connecting rods. First of all wipe the oil off of the connecting rod journal and then grease the upper bearing insert, place it in the connecting rod centering it. Put the point A and point B; the measurement should be not more than 0.50mm (0.0196 in.). To assemble the rod and pistons use the piston ring compressor and Guide Pins Special Tool 8507 then assure that the oil slinger slots in the rods are facing forward on the engine and that the Fs near the piston wrist pin bore are facing forward. Insert lower bearing insert in the bearing cap so that center falls in the center hole of cap and make the lower insert dry. position a strip of Plastigage completely across the lower insert span which is at the centre of the bearing cap and it should not crumble rather get a newly made stock. Install bearing cap and connecting rod on journal, tighten bolts to 27 Nm (20 ft. lbs.) plus 90 degree turn, do not turn crankshaft enough to smear Plastigage, which would give an inaccurate indication on the dial of the pressure. It should include removal of bearing cap and measuring the width of compressed Plastigage to give bearing-to- journal clearance, consulting Engine Specifications to give correct clearance. The Plastigage has to show the clearance at the same reading along the entire width of the insert; a variation can denote a tapered journal or bent connecting rod or some foreign material lodged between insert and cap or rod. When the proper clearance is marked, in that case, nothing needs to be done with regard to the replacement of these bearing inserts; the Plastigage placed across the crankshaft journal and bearing insert is to be removed so that the insertion process could be continued. In case the bearing-journal clearance is more than the specification, then identify under what bearing set to make use of, and remember that the connecting rod bolts should be Torque to Yield Bolts, and they are not to be reused, so, in all cases when any of the rod bolts is loosened or distracted, replace them. Repeat the plastigage reading to ensure the choice of bearing that you use before final assembly. After choosing the correct insert, insert and cap, and torque the connecting rods bolts to 27 Nm (20 ft. lbs.) and add a 90 degree turn. Put a tight-fitting feeler gauge between the connecting rod and crankshaft journal sleeve and check Engine Specifications to determine how much clearance should be and replace the connecting rod when side clearance is not within specification.

- Q: How to Assess Rod Bearing Alignment and Wear on Jeep Grand Cherokee?A:Inspect the rod bearings for normal wear patterns as you check for bends in the tabs, grooves, pits, scoring and fatigue and put in new bearings for any of those that show signs of unusual wear. Take a look at the journals on the connecting rods to see if there are any scrapes, score marks or burrs, since misalignment or bends in the connecting rod can damage the Pistons, piston rings, the cylinder walls, the connecting rod bearings and the Crankshaft's connecting rod journals. Should the usage show that the connecting rod is not straight, adjust it correctly or replace any badly connected parts. Clean the rod journal, insert the short rubber hose over the rod bolts, cover only the bearing insert with oil, fasten the upper bearing into the connecting rod and when installing, point the ring grooves of the piston to the front of the engine. Place the lower bearing insert in the bearing cap, make sure it's not damp, put Plastigage over the entire insert in the center of the cap. Put on the bearing cap and connecting rod onto the journal, but do not tighten the bolts past 45 Nm (33 ft. lbs.) or else the Plastigage will get smeared. With the bearing cap removed, measure the compressed Plastigage and check if the bearing-to-journal clearance measured is the same throughout the insert's width. Any difference might suggest a tapered journal, bent connecting rod or things stuck between the journal and the cap or rod. If the clearance is right, take out the Plastigage and carry on stalling; if it goes beyond useful clearance standards, put in two undersize bearing liners and ensure all odd-size inserts are at the bottom, then test the gap once more. With the smaller-than-normal inserts, the distance between the part and the cutting tool is evaluated to see if any other changes are needed. Take, for example, when the clearance is 0.0762 mm (0.003 inch)-if you use inserts that are 0.025 mm (0.001 inch) undersize, the clearance drops to 0.002 inch which is acceptable. Start by doing the Plastigage test again after choosing the bearing and once you have the right one, put it in place with the cap and fasten with 45 Nm (33 ft. lbs.) of torque. To check side clearance, slide a tight feeler gauge inside the gap between the connecting rod and crankshaft flange. If the measurement isn't right, put in a replacement connecting rod.