JeepParts

My Garage

My Account

Cart

OEM 2004 Jeep Grand Cherokee Universal Joint

U-Joint- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Universal Joint found

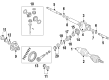

2004 Jeep Grand Cherokee Universal Joints Part Number: 5015694AB

$81.00 MSRP: $124.00You Save: $43.00 (35%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Universal Joint; CV Joint; U Joint; Front Universal Joint; Universal Joint Kit

- Replaces: 5015694AA, 3555556193, 4882793

- Item Weight: 1.60 Pounds

- Item Dimensions: 1.7 x 6.1 x 7.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5015694AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2004 Jeep Grand Cherokee Universal Joint Parts and Q&A

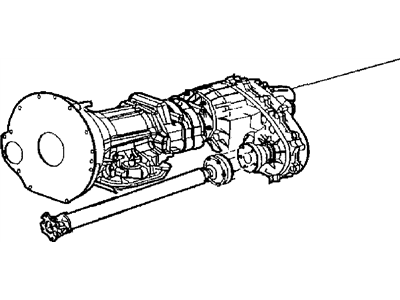

- Q: How to Maintain and Repair Universal Joints on 2004 Jeep Grand Cherokee?A: First, take out the propeller shaft to service and repair single cardan universal joints. Rap the outer edge of the bearing cap assembly with a drift to release the edges of the first snap ring and then remove both snap rings from the yoke. Set up the bearing cap in the arbor press or vise with a socket large enough, putting the yoke above it and aligning the fitting with the arrow if your bearing has one. Put a socket that fits snugly around the upper bearing cap onto the upper part and screw it down to let the lower bearing cap slide off. If you cannot straighten the bearing cap by hand, hit the yoke ear close to the cap using a nonmetal tool. To remove the opposite bearing cap, invert the yoke, straighten the cross in the exposed hole and gently push down on the cross end to take out that bearing cap. While installing the unit, position the cross and bearing cap so they are straight to keep the yoke bore walls from being harmed. Grease the yoke's inside base with EP N.L.G.I. Grade 1 or 2 grease, line up the cross bolt with the yoke, keeping its lube fitting upward if present and then set a bearing cap on the trunnion with the needle bearings facing up. Load the yoke bore with the cap by hand to get past the snap ring location and then fit a snap ring into place. Go on to install the other bearing cap in the same way. If the joint does not move smoothly, hammer the yoke with a soft tool to slide the needle bearings in place, add grease to the lube fitting from the yoke and secure the propeller shaft.