JeepParts

My Garage

My Account

Cart

OEM 2006 Dodge Caravan Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Crankshafts found

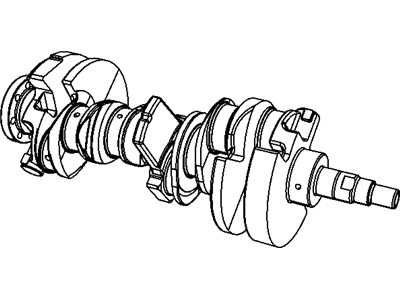

2006 Dodge Caravan Crankshaft Part Number: 4621983AD

$299.79 MSRP: $1045.00You Save: $745.21 (72%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Crankshft

- Replaces: 4621983AB

- Item Weight: 47.30 Pounds

- Item Dimensions: 25.8 x 8.2 x 8.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4621983AD

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

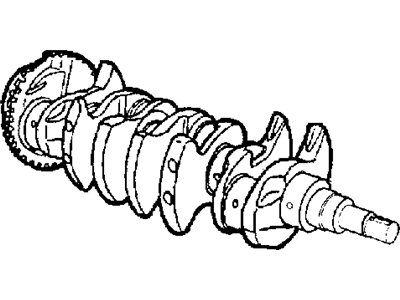

2006 Dodge Caravan Crankshaft Part Number: 4781643AA

$539.13 MSRP: $818.00You Save: $278.87 (35%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Crankshft; Crankshaft Includes Target Ring And Screw

- Item Weight: 47.80 Pounds

- Item Dimensions: 24.5 x 8.8 x 8.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4781643AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2006 Dodge Caravan Crankshaft Parts and Q&A

- Q: How to Remove and Install a Crankshaft in an Engine Assembly on 2006 Dodge Caravan?A: Before removing the crankshaft, first get the engine out of the car and next remove the transaxle from it. After that, take out the drive plate/flex plate. The rear part of the crankshaft oil seal needs to be removed and then the engine can be stood on a repair stand. Empty the oil tank, remove the oil filter and take off the crankshaft vibration damper and the bracket supporting the engine mount. After that, take off the front timing belt covers, the timing belt, the rear timing belt cover and the oil pan and finally the oil pump pick-up tube. Get rid of the crankshaft sprocket, oil pump, balance shafts and housing and crankshaft position sensor. Whenever piston or connecting rod replacement is necessary, the cylinder head must be taken off. Rather than numbering each connecting rod cap using a stamp or punch, mark them with a permanent ink or paint marker. Remove every connecting rod bolt and cap carefully, not damaging the fracture rod and cap and replace all the bolts. Remove every bolt from the bed plate and use a gentle tap to free the bed plate from the dowel pins, making sure you remove it evenly. Be sure not to harm the main bearings or journals when you lift the crankshaft out and unscrew the target ring fixings before you pull off the target ring. Look for any excessive wear, taper or scoring on the crankshaft journals, checking that tolerance for taper or being out of round keeps within 0.025 mm (0.001 inch) and that the journal grinding does not exceed 0.305 mm (0.012 inch) on the size of the journal used for grinding. Ensure the main bearing upper shells are put in with their lubrication grooves and oil holes matching and use Mopar6 brake parts cleaner to clean both the crankshaft and target ring while installing the crankshaft. Receive new mounting screws, tighten them in order to 13 Nm (110 inch lbs.) using the series mentioned in the manual and apply some oil to both the bearings and journals before installing the crankshaft. Place Mopar Bed Plate Sealant only on the bed plate, attach the lower main bearings to the main bearing cap/bed plate and make a 1.5 to 2.0 millimeter sealant bead across the bed plate. Place the main bearing/bed plate into the engine block, oil the bolts and fasten them, one at a time, to make sure the thrust bearing is straight. After completing the bed plate process, look at both the crankshaft turning torque, making sure it stays below 5.6 Nm (50 inch lbs.) and the crankshaft end play. Add the connecting rod bearing and cap, tighten the connecting rod bolts to 27 Nm (20 ft. lbs.) with an additional 1/4 turn and set up the balance shafts and housing in place, torquing all related bolts to 28 Nm (20 ft. lbs.). Put the oil pan, crankshaft position sensor and cylinder head in place first, if needed and then place the timing belt rear cover, crankshaft sprocket, timing belt and front timing belt covers. As your last step, attach the engine support bracket, put in a new oil filter, fit the crankshaft rear oil seal and secure the flex plate with Mopar Lock & Seal Adhesive on the threads and fastened tightly. After you attach the transaxle to the engine, fasten the bolts to 101 Nm (75 ft. lbs.) and reassemble the engine.