JeepParts

My Garage

My Account

Cart

OEM 2006 Dodge Ram 2500 Drive Shaft

Axle Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

24 Drive Shafts found

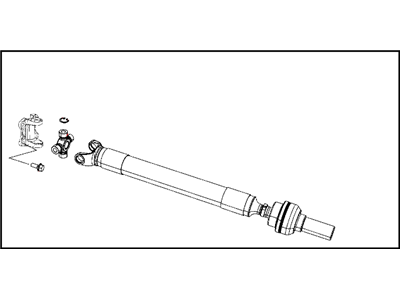

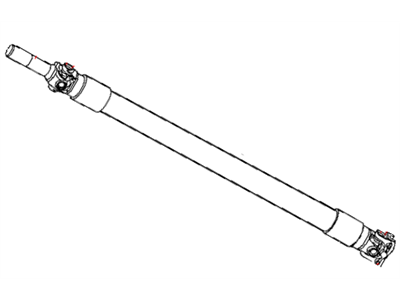

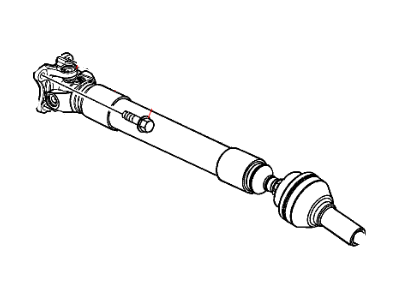

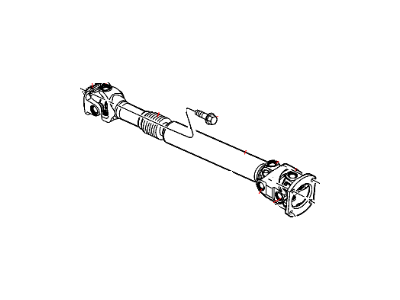

2006 Dodge Ram 2500 Drive Shaft Part Number: 52123021AC

$1036.23 MSRP: $1525.00You Save: $488.77 (33%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shaft - Drive; Driveshaft; Shaft Drive Front

- Replaces: 52123021AB, 52123021AA, 52105990AB

- Item Weight: 16.00 Pounds

- Item Dimensions: 39.8 x 6.1 x 6.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52123021AC

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

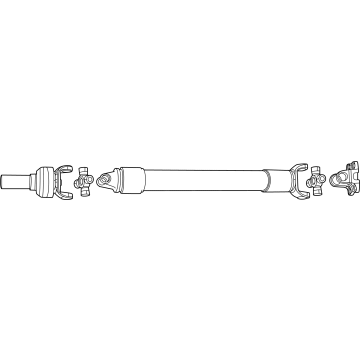

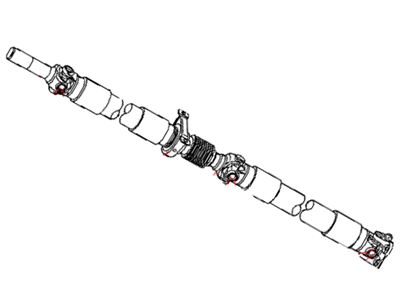

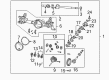

2006 Dodge Ram 2500 Drive Shaft Part Number: 52123104AB

$1685.13 MSRP: $2575.00You Save: $889.87 (35%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Shaft - Drive; Driveshaft

- Replaces: 52123104AA, 52853186AC

- Item Weight: 77.00 Pounds

- Item Dimensions: 88.9 x 10.6 x 7.7 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52123104AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

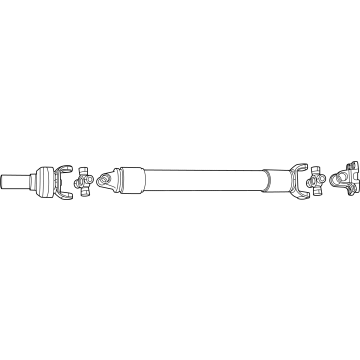

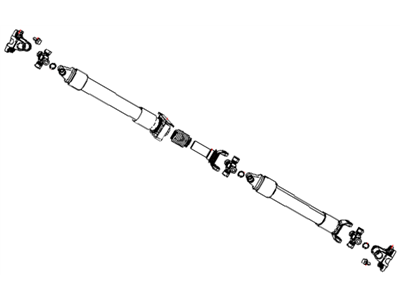

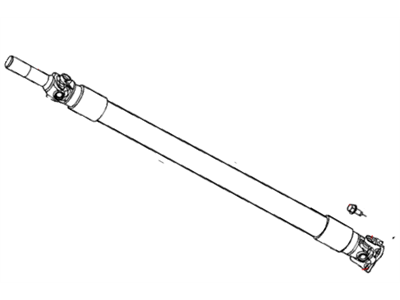

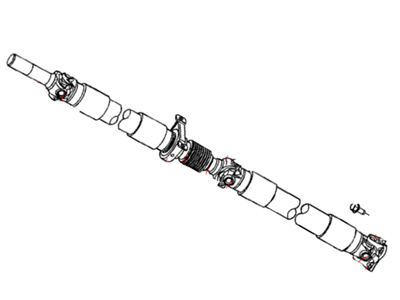

2006 Dodge Ram 2500 Drive Shaft Part Number: 52123117AC

$1110.53 MSRP: $1700.00You Save: $589.47 (35%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Shaft - Drive; Driveshaft; Shaft Drive Rear 1-Piece

- Replaces: 5146475AA, 52123117AA, 52123117AB, 52105809AE

- Item Weight: 36.80 Pounds

- Item Dimensions: 102.0 x 5.4 x 5.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52123117AC

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

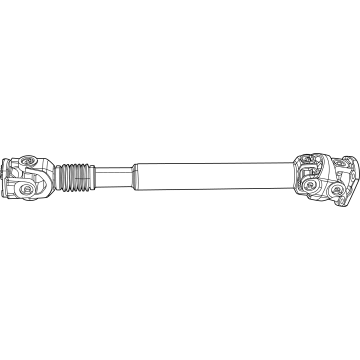

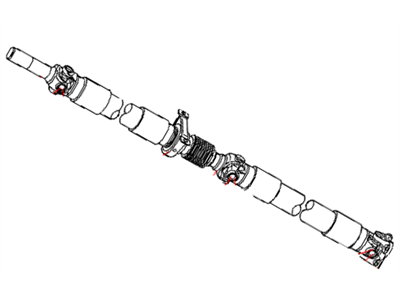

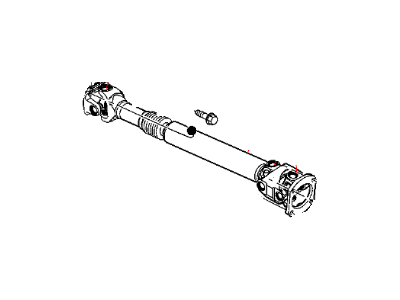

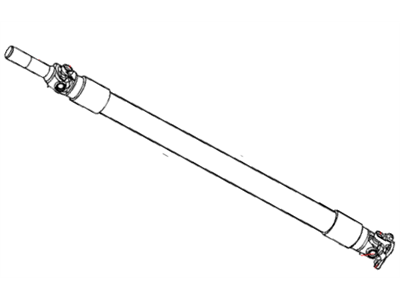

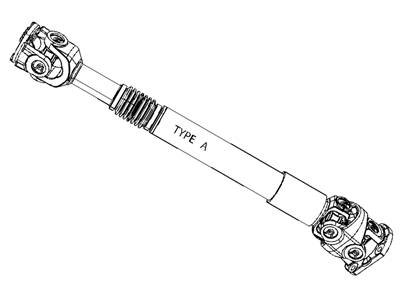

2006 Dodge Ram 2500 Drive Shaft Part Number: 52123326AD

$1017.21 MSRP: $1505.00You Save: $487.79 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Shaft-Drive

- Replaces: 52105934AF, 52123112AA, 52123326AA, 52123326AC, 52105934AB, 52105934AD, 68057601AA, 52105934AC, 52105934AE, 52123326AB

- Item Weight: 30.60 Pounds

- Item Dimensions: 40.8 x 8.2 x 5.3 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52123326AD

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2006 Dodge Ram 2500 Drive Shaft Part Number: 52123129AE

$898.37 MSRP: $1360.00You Save: $461.63 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Shaft - Drive; Driveshaft; Shaft Drive Rear 1-Piece

- Replaces: 52123129AB, 52105633AE, 52123129AA, 52123129AC, 52123129AD

- Item Weight: 41.60 Pounds

- Item Dimensions: 95.6 x 10.4 x 9.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52123129AE

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2006 Dodge Ram 2500 Drive Shaft Part Number: 52123121AC

$994.14 MSRP: $1410.00You Save: $415.86 (30%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Shaft - Drive; Driveshaft; Shaft Drive Rear 1-Piece

- Replaces: 52123121AA, 52123121AB

- Item Weight: 38.20 Pounds

- Item Dimensions: 67.2 x 5.3 x 4.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52123121AC

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2006 Dodge Ram 2500 Drive Shaft Part Number: 52123105AB

Product Specifications- Other Name: Shaft - Drive; Driveshaft

- Replaces: 52123105AA

- Item Weight: 56.90 Pounds

- Item Dimensions: 93.6 x 9.0 x 8.9 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52123105AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2006 Dodge Ram 2500 Drive Shaft Part Number: 52123122AA

Product Specifications- Other Name: Shaft - Drive; Driveshaft; Shaft Drive Rear 1-Piece

- Replaces: 52853185AC

- Item Weight: 35.30 Pounds

- Item Dimensions: 71.3 x 4.9 x 4.9 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52123122AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2006 Dodge Ram 2500 Drive Shaft Part Number: 52123100AB

Product Specifications- Other Name: Shaft - Drive; Driveshaft

- Replaces: 52105810AF, 52123100AA

- Item Weight: 79.40 Pounds

- Item Dimensions: 88.9 x 9.0 x 9.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52123100AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2006 Dodge Ram 2500 Drive Shaft Part Number: 52123138AC

Product Specifications- Other Name: Shaft - Drive; Driveshaft

- Replaces: 52123138AA, 52123138AB

- Item Weight: 20.60 Pounds

- Item Dimensions: 88.7 x 8.2 x 8.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52123138AC

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2006 Dodge Ram 2500 Drive Shaft Part Number: 52123110AC

Product Specifications- Other Name: Shaft - Drive; Driveshaft

- Replaces: 52123110AB, 52105930AC, 52105930AE, 52105930AF, 52105930AD, 52105930AB, 52123110AA

- Item Weight: 26.80 Pounds

- Item Dimensions: 5.2 x 5.2 x 33.7 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52123110AC

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2006 Dodge Ram 2500 Drive Shaft Part Number: 52105993AB

Product Specifications- Other Name: Shaft - Drive; Driveshaft; Shaft Drive Front

- Item Weight: 18.80 Pounds

- Item Dimensions: 41.7 x 5.8 x 5.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52105993AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2006 Dodge Ram 2500 Drive Shaft Part Number: 52105653AF

Product Specifications- Other Name: Shaft - Drive; Driveshaft; Shaft Drive Rear 1-Piece

- Item Weight: 35.60 Pounds

- Item Dimensions: 67.4 x 6.9 x 6.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52105653AF

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2006 Dodge Ram 2500 Drive Shaft Part Number: 5037437AB

Product Specifications- Other Name: Shaft - Drive; Driveshaft; Shaft Drive Rear 1-Piece

- Item Weight: 16.60 Pounds

- Item Dimensions: 68.5 x 6.1 x 6.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5037437AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2006 Dodge Ram 2500 Drive Shaft Part Number: 52105931AF

Product Specifications- Other Name: Shaft - Drive; Driveshaft

- Replaces: 52105931AD, 52105931AC, 52105931AE, 52105931AB

- Item Weight: 73.80 Pounds

- Item Dimensions: 35.0 x 5.3 x 5.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52105931AF

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2006 Dodge Ram 2500 Drive Shaft Part Number: 52123131AD

Product Specifications- Other Name: Shaft - Drive; Driveshaft

- Replaces: 52123131AB, 52123131AC, 52123131AA

- Item Weight: 30.50 Pounds

- Item Dimensions: 81.7 x 4.9 x 4.9 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52123131AD

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2006 Dodge Ram 2500 Drive Shaft Part Number: 52123148AC

Product Specifications- Other Name: Shaft - Drive; Driveshaft

- Replaces: 52123148AB, 52123097AA, 52123148AA

- Item Weight: 38.00 Pounds

- Item Dimensions: 92.5 x 9.4 x 8.9 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52123148AC

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2006 Dodge Ram 2500 Drive Shaft Part Number: 52123132AB

Product Specifications- Other Name: Shaft - Drive; Driveshaft

- Replaces: 52123132AA, 52105634AF

- Item Weight: 71.40 Pounds

- Item Dimensions: 89.8 x 9.0 x 9.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52123132AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2006 Dodge Ram 2500 Drive Shaft Part Number: 68229944AA

Product Specifications- Other Name: Shaft - Drive; Driveshaft

- Replaces: 52123140AA

- Item Weight: 74.70 Pounds

- Item Dimensions: 92.5 x 9.0 x 9.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 68229944AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2006 Dodge Ram 2500 Drive Shaft Part Number: 52123111AC

Product Specifications- Other Name: Shaft - Drive; Driveshaft

- Replaces: 52123111AB, 52123111AA

- Item Weight: 28.40 Pounds

- Item Dimensions: 36.6 x 5.1 x 4.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52123111AC

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

| Page 1 of 2 |Next >

1-20 of 24 Results

2006 Dodge Ram 2500 Drive Shaft Parts and Q&A

- Q: How to Service and Repair a Drive Shaft While Ensuring Proper Propeller Shaft Angles on 2006 Dodge Ram 2500?A: Begin service and repair of the propeller shaft by raising your vehicle, ensuring the axles are equally straight, so the wheels and shaft can move. Set the inclinometer on the machined surface of the C/V joint for A when using a front shaft with a C/V joint. Make sure universal joint snap rings are removed for a flat surface. Roll the shaft until the transmission or transfer case output yoke bearing is turned downward. The measurements of every wheel must be taken front to back on the same side each time. Add the Inclinometer 7663 to the yoke bearing cap or pinion flange ring next to the shaft, level it parallel to the shaft and take the measurement A for the transmission yoke Output Angle. Turn the propeller shaft 90 degrees and sit the inclinometer on the yoke bearing so that it runs along with the shaft and is parallel to it. With the bubble in the center of the sight, read the Propeller Shaft Angle which can also be taken from where the shaft ends at the ship's rear. Change the shaft position by another 90 degrees and position the inclinometer at an angle parallel to the shaft on the companion flange yoke bearing, so the bubble in the sight glass is centered for Companion Flange Input Angle B. First, find the Transmission/Transfer Case Output Operating Angle by subtracting A from C and for the axle Input Operating Angle, deduct B from C. The operating angle of a U-joint should be less than 1 degree when possible, but at least 1/2 of one degree for the continuous operating propeller shaft angle. A two-piece propeller shaft is measured in the same way as a one-piece shaft.