JeepParts

My Garage

My Account

Cart

OEM 2006 Jeep Commander Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Crankshafts found

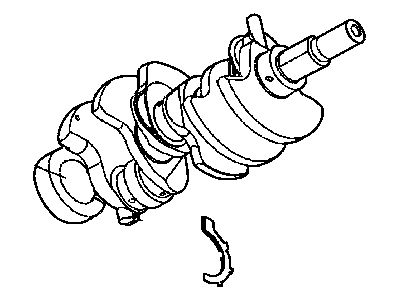

2006 Jeep Commander Crankshaft Part Number: 53020959AB

$629.85 MSRP: $959.00You Save: $329.15 (35%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Crankshft; Crankshaft See Note

- Item Weight: 48.20 Pounds

- Item Dimensions: 28.4 x 10.1 x 8.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 53020959AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

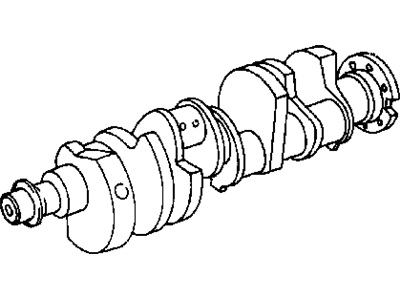

2006 Jeep Commander Crankshaft Part Number: 53021302AD

Product Specifications- Other Name: Crankshft; Crankshaft Includes Tone Ring And Tone Ring Mounting Screws

- Item Weight: 64.00 Pounds

- Item Dimensions: 29.6 x 8.5 x 7.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 53021302AD

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

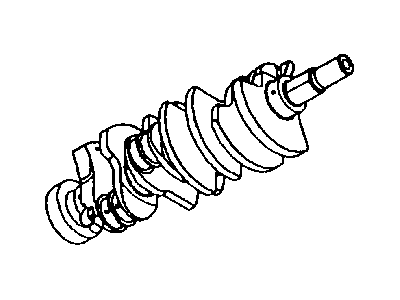

2006 Jeep Commander Crankshaft Part Number: 53021387AA

Product Specifications- Other Name: Crankshft

- Item Weight: 59.60 Pounds

- Item Dimensions: 30.6 x 9.3 x 7.9 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 53021387AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2006 Jeep Commander Crankshaft Parts and Q&A

- Q: How to Extract the Crankshaft from an Engine on 2006 Jeep Commander?A: Take out the engine from the vehicle, then remove the engine oil pump to lift off the crankshaft. Be careful not to press on the oil pan gasket, since it attaches to the cylinder block at three points and can't be gotten at with the pan removed. After that, take out the bedplate bolts, remember where the two stud bolts go and carefully take out the connecting rods, making certain not to harm the sealing surface between the bedplate and the block. Hands should be used to carry the lower main bearing halves in the bedplate, since incorrect handling or installation of the bearing halves can severely harm the crankshaft. Loosen and take off the bedplate by using the pry points and when removing the crankshaft, don't damage the surfaces of its bearings. Look for signs such as scoring, blueing or serious scratches in the connecting rod bearing bores and main bearing bores, because further disassembly may be required. Should the connecting rod bearing bores have damage, the cylinder is removed to reach the rods and pistons; if the main bearing bores in bedplate or cylinder block are damaged, the complete engine must be changed. Should you need to, remove the main bearing halves from the cylinder block and bedplate, carefully clean the areas where the bearings contact the block, inspect the main bearing bores in the bedplate for cracks or overheating (Called "severe blueing") and change the engine if you notice any of these abnormalities. Inspect the thrust washers on the crankshaft for marks of scoring, scratches, wear or blueing and replace them if needed and do the same if you notice splits, tears or cracks in the oil pan gasket. The main bearings should be installed using a snug fit and ensure you don't harm the surfaces of the crankshaft's bearings. Add sealant to the tone wheel screws, use clean oil to coat the upper bearing halves before assembly, lower the crankshaft into the cylinder block and set the thrust washers in place. Applying Mopar Engine Rtv sealant to the bedplate-to-cylinder block surface prevents severe oil leaks, while keeping both surfaces clean. Add a thin layer of Mopar Engine Rtv Sealant to the mating area, put clean oil on the crankshaft main bearing journals and put the bedplate into position on the cylinder block. Lubricate the clamp bolts with clean engine oil just before installing, attach the bolts and check that their studs are in the correct place as you secure them following the torque specification. Measure the crankshaft end play, after that install the connecting rods and record the side clearance, place the oil pump and lastly reinstall the engine.