JeepParts

My Garage

My Account

Cart

OEM 2008 Dodge Challenger Sway Bar Kit

Stabilizer Sway Bar Set- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Sway Bar Kits found

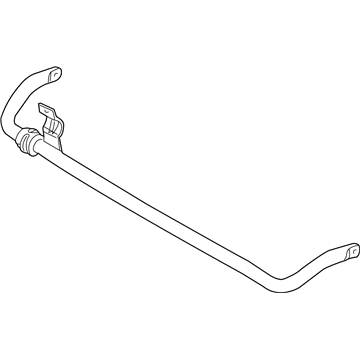

2008 Dodge Challenger Stabilizer Bar, Front Part Number: 4782544AC

Product Specifications- Other Name: Bar - Front; Suspension Stabilizer Bar, Front; Sway Bar; Stabilizer Bar Front

- Position: Front

- Replaces: 4782544AB

- Item Weight: 15.60 Pounds

- Item Dimensions: 39.7 x 10.3 x 2.9 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4782544AC

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

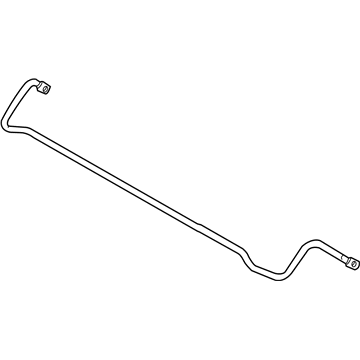

2008 Dodge Challenger Stabilizer Bar, Rear Part Number: 4782872AB

Product Specifications- Other Name: Bar - Rear Suspension; Suspension Stabilizer Bar, Rear; Sway Bar; Stabilizer Bar Rear Suspension; Bar Rear Sway

- Position: Rear

- Item Weight: 5.80 Pounds

- Item Dimensions: 55.9 x 10.6 x 5.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4782872AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2008 Dodge Challenger Sway Bar Kit Parts and Q&A

- Q: How to Install a Sway Bar Kit for Rear Suspension on 2008 Dodge Challenger?A: Before you fit the rear suspension sway bar kit, place isolators on it first, so that the slits in the bushings are up front and the flat side of the isolators is facing the crossmember. After that, add retainers to the isolators and insert them and the sway bar kit onto the crossmember. Set the isolator retainer mounting bolts in place but don't fasten them yet; then connect the sway bar kit ends to the sway bar links using bolts and nuts, not tightening either. Tighten the bolts for the isolator retainer bracket to 61 Nm (45 ft. lbs.). First, take out the coil springs with isolators from the spring links, lift the crossmember until it reaches the body points, slide the propeller shaft onto the rear axle differential flange and position the shocks in the spring link pockets. The screws at the back are longer than those at the front, so do not mix them up. Raise the crossmember until you reach the point where you can connect the bolts, but don't tighten them yet on the left side. Set the jack down so the right crossmember drops enough for you to work with the springs while the isolators are securely installed on both sides. Slide the coil spring into the spring pocket and line it up with the body mount, then using the jack, bring the vehicle up to position the coil spring and lower end of the shock with the spring link mount. Mount the lower shock bolt and nut onto the chassis for now without tightening. Before lifting the AWD vehicle's crossmember, put spacers over the right mount bushings. Lift up the right side of the crossmember until it is seated and bolt it on while leaving the bolts just snug. Carry out the job in reverse: remove the left side crossmember mounting bolts, then, with the jack, place the body at a height so you can lower the crossmember and correctly position the isolators. Place the coil into the spring pocket, position it alongside the body mount and use the jack to pipe both the coil spring and the lower part of the shock absorber through the car body until they line up. Attach the lower shock mounting bolt and nut, but don't tighten them yet. When installing an AWD vehicle, put spacers on the left crossmember mount bushings before lifting the crossmember. Place the left side of the crossmember and install the bolts on that side, but don't tighten them fully yet. Position the crossmember as wanted to fit with the marks on the body and use a ruler to check that the tension link-to-weld-flange distance is no less than 12 mm for smooth suspension. If that doesn't reach the right distance, fasten and butt the crossmember 1.25-1.5 inches (3-4 cm) rearward to achieve it, then retighten the bolts and check again. Make sure all four crossmember mounting bolts are turned to 180 Nm (133 ft. lbs.), remove the jack under the rear axle differential and also remove the bungee cord tied to the propeller-shaft. Match the rear shaft to the coupler index marks and screw in the flange mounting bolts and nuts until they register 81 Nm (60 ft. lbs.). Set the fuel filler tube in place, wire the left rear wheel speed sensor cable near the body connector and link the left rear wheel speed sensor with the right sensor connector. Plug the speed sensor connectors into the luggage compartment floor pan connector and ensure the retaining clip is correctly in place. When you're installing caliper guide pin bolts, clean the holes and cover them with Mopar(R) Lock AND Seal Adhesive or a similar brand. Push the guide pins into the adapter for disc brakes, feed the caliper and hose down through the back of the suspension and place the caliper on the adapter over the brake pads. Set the holes in the caliper to match the guide pins, put in the guide pin bolts and tighten them to 31 Nm (23 ft. lbs.) so the brake hose isn't crushed. With the SRT8 disc version, lift the spring link using a jack, position the caliper over the brake rotor and wind in the caliper securing bolts to 96 ft. lbs. (130 Nm). Get rid of the jack from the spring link, slot the pink bracket through the front flange of the crossmember and screw the parking brake cable bracket right on the rear crossmember. Hold the cable to guide it past the rear crossmember, then push it through the equalizer directly over the differential at the back axle. Attach the front parking brake cable to the rear parking brake cable on the right hand side. First, fit the exhaust system at the rear and then put on the tire and wheels. Afterwards, tighten the wheel mounting nuts to 150 Nm (110 ft. lbs.) or 190 Nm (140 ft. lbs.) for police vehicles only. Once the rear wheels come to within a centimeter or so from floor level, press the parking brake lever, release it, push it again to be sure the rear wheels do not roll. Set the vehicle down and link the negative cable on the battery to the main terminal securely. Push the brake pedal a few times to confirm it is secure before putting the car in drive. To access the lower mounting bolt nuts, raise the vehicle where needed, then tighten them to 72 Nm (53 ft. lbs.), together with the sway bar link fasteners which should be tightened to 61 Nm (45 ft. lbs.). Wheel alignment should be performed in the end, focusing on the thrust angle and if the crossmember has to move to align the angle, check that the tension link does not rub.