JeepParts

My Garage

My Account

Cart

OEM Chrysler 300 Piston

Engine Pistons- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

17 Pistons found

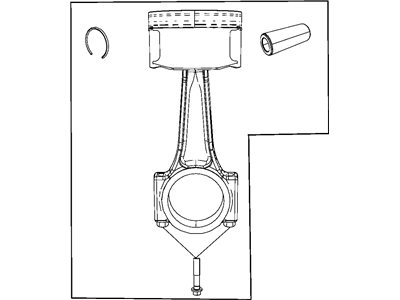

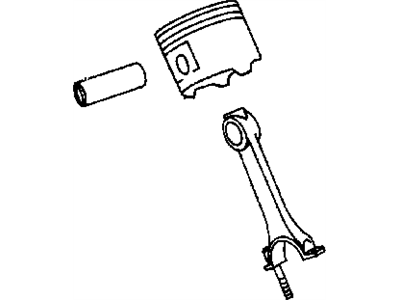

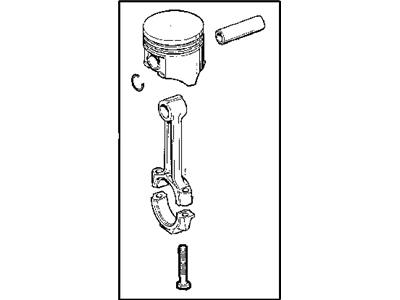

Chrysler 300 Connecting Rod Part Number: 68090672AA

$291.72 MSRP: $439.00You Save: $147.28 (34%)

Chrysler 300 Piston Part Number: 68067541AA

$253.77 MSRP: $292.00You Save: $38.23 (14%)Ships in 1-2 Business Days

Chrysler 300 Connecting Rod Part Number: 68090673AA

$295.71 MSRP: $435.00You Save: $139.29 (33%)Ships in 1-2 Business Days

Chrysler 300 Connecting Rod Part Number: 53022257AE

$221.23 MSRP: $328.00You Save: $106.77 (33%)Chrysler 300 Piston Part Number: 5018627AD

$316.65 MSRP: $576.00You Save: $259.35 (46%)Ships in 1-2 Business DaysChrysler 300 Connecting Rod Part Number: 53022258AE

$216.40 MSRP: $318.00You Save: $101.60 (32%)Ships in 1-2 Business Days

Chrysler 300 Piston Part Number: 5086011AB

Chrysler 300 Piston Part Number: 5086010AB

Chrysler 300 Piston Part Number: 68031891AD

Chrysler 300 Piston Part Number: 68031890AD

Chrysler 300 Piston Part Number: 53021539AD

Chrysler 300 Piston Part Number: 53021538AD

Chrysler 300 Piston Part Number: 5037491AB

Chrysler 300 Piston Part Number: R4892194AB

Chrysler 300 Piston Part Number: 53022258AC

Chrysler 300 Piston Part Number: 53022257AC

Chrysler 300 Piston Part Number: 5159461AA

Chrysler 300 Piston

Choose OEM Piston that meet Chrysler factory standards. Chrysler designs and tests every component for precision and durability. Each Piston follows strict manufacturing steps to lock in quality and fit. If your Chrysler 300 matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine 300 parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

Chrysler 300 Piston Parts and Q&A

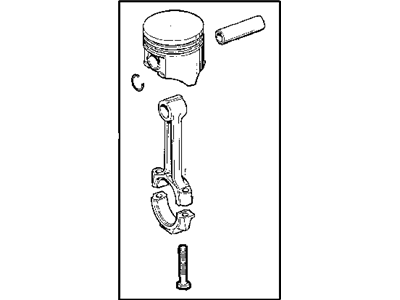

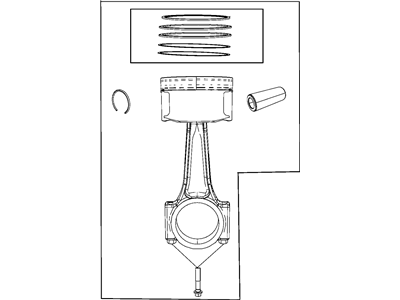

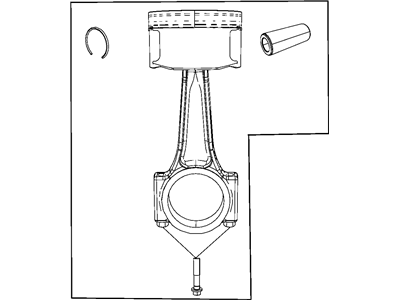

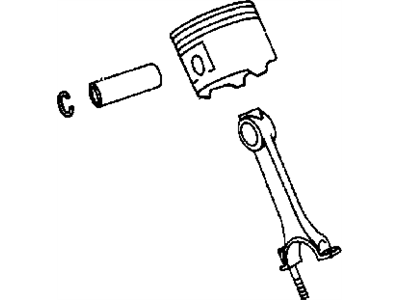

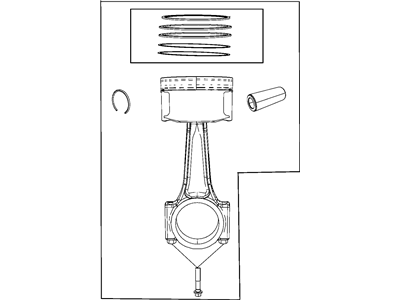

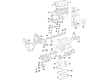

- Q: How to Remove and Replace Piston Assemblies on Chrysler 300?A:The first step is to use a trustworthy ridge reamer to clean up the top ridge in the bores, while still protecting the tops of each piston. Turn the Crankshaft until every connecting rod is straight in the middle of its connected cylinder bore when you pull it out. Mark where the connecting rod and bearing caps go, using a permanent marker or scribe tool, so you don't damage the surfaces of the joints. Lift off the connecting rod cap, place Special Tool 8189 Connecting Rod Guides over the exposed connecting rod and pull each piston and rod out of the cylinder bore, making sure the crankshaft journals aren't scratched. When the bearing is removed, replace the bearing cap on the rod to shield the fractured spots. First, put the piston rings in and be sure to arrange the staggered gaps of the compression rings with the mated ends of the oil ring expanders as they should be applied to the rails. Put the stripped piston and rings into clean engine oil, put the ring compressor over the piston and use the special wrench to tighten until the ring positions stay the same. Line up the hole in the bearing's half with the one in the connecting rod, cover the bearing with clean engine oil and set the rods in place with Special Tools 8189 Connecting Rod Guides. On both cylinder sides, the piston with the arrow and "F" should stand in the front of the engine, with its connecting rod oil squirt hole facing the major thrust side of the block. Use the crankshaft to center the connecting rod journal where it belongs in the cylinder bore, add the rod and piston and swing the rod across the crankshaft journal. Use a hammer handle to press the piston down into the cylinder bore as you control the connecting rod's placement. After that, coat the rod bolts and bearing surface with engine oil, set the connecting rod into place and bolt it down securely to 27 Nm (20 ft. lbs.), plus turn it an extra 1/4 rotation.

- Q: How to Assemble Piston and Connecting Rod Components on Chrysler 300?A:Before installing the piston and connecting rod assemblies, first put in the piston rings in an order where the compression ring gaps are not aligned with the oil ring rail gaps. The place for oiling in the connecting rod is on the cylinder bore's left side when you look at the engine from the front with the pan rail lowered. Ensure the ring compressor connection will work smoothly by ensuring both the oil ring expander ends are touching and the rails are positioned right. Apply engine oil to the piston and rings, install the compressor over the top of the piston and use the special tool to tighten, being careful not to alter the arrangement of the rings. Mate the holes of the bearing half with the holes of the connecting rod, then set the bearing in place and moisten its surface with clean engine oil. Help the connecting rod receive Special Tools 8189 Connecting Rod Guides. There are arrows above the pin bosses on the pistons and an "F" should point toward the front of the engine, as the oil squirt hole on the connecting rod faces the side with more force on both cylinder banks. After rotating the crankshaft, set the connecting rod journal in the center of the cylinder bore, slide the rod inside the bore with the help of the journal and insert the piston into it. Stick the connecting rod between the journal and the piston and then tap down the piston with a hammer. After finishing, coat the rod bolts and bearing surface with oil, place on the connecting rod cap and bearing and tighten to 27 Nm (20 ft. lbs.) more than 1/4 turn.