JeepParts

My Garage

My Account

Cart

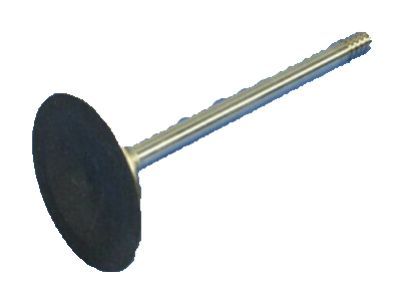

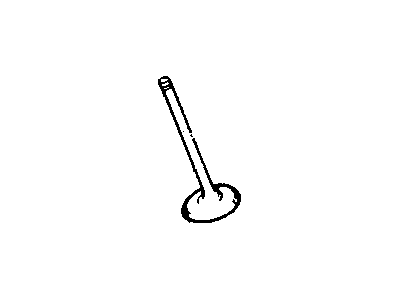

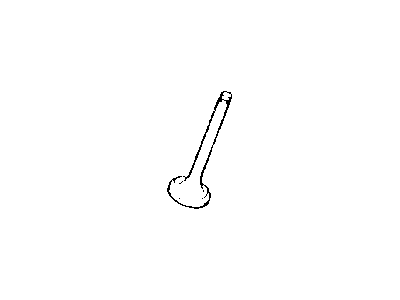

OEM Dodge Caravan Intake Valve

Engine Intake Valve- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Intake Valves found

Dodge Caravan Intake Valve Part Number: 4781025AA

$37.05 MSRP: $54.30You Save: $17.25 (32%)Ships in 1-2 Business DaysDodge Caravan Intake Valve Part Number: 4298137

$14.79 MSRP: $17.00You Save: $2.21 (13%)Ships in 1-2 Business DaysDodge Caravan Intake Valve Part Number: 4448052

$3.50 MSRP: $4.43You Save: $0.93 (21%)Ships in 1-2 Business DaysDodge Caravan Intake Valve Part Number: 4694222

$4.58 MSRP: $5.80You Save: $1.22 (22%)Ships in 1-2 Business DaysDodge Caravan Intake Valve Part Number: 4884691AA

$26.23 MSRP: $33.60You Save: $7.37 (22%)Ships in 1-2 Business Days

Dodge Caravan Intake Valve Part Number: 4667969

Dodge Caravan Intake Valve Part Number: MD088811

Dodge Caravan Intake Valve Part Number: 4323244

Dodge Caravan Intake Valve

Choose OEM Intake Valve that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Intake Valve follows strict manufacturing steps to lock in quality and fit. If your Dodge Caravan matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Caravan parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

Dodge Caravan Intake Valve plays the essential role which affects the efficiency and durability of the cars of Dodge Caravan. Headed by the intake valve, one of the most important components in any car engine, it controls the rate at which air and fuel is supplied and thus determines the engine power and efficiency of combustion. This reliability is rather critical as any malfunction of the Intake Valve leads to poor performances of the engine and combustion system thus general driving experience. Built for use with the Dodge Caravan, and particularly the Dodge Grand Caravan, the Intake Valve works in helping every car to run at its optimum, further helping saving on both fuel and improving safety. The Dodge Caravan Intake Valve is not like any other model in the market since it owes its uniqueness to precision engineering and material qualities that are meant to stand test of time and usage. Some of its characteristics include the high capability for airflow and construction that prevents damages during the functioning. This explains why the Dodge Caravan has been in production for more than three decades and why the Intake Valve of the vehicle is considered to be very reliable for families and individuals. Thus the Intake Valve stays with the Dodge Caravan as it evolves to suit the market and consumers, so that people can drive in a stable, efficient and secure manner. Therefore, the role that the Dodge Caravan Intake Valve is quite vital to the overall effectiveness of Dodge Caravan vehicles establishing it's value in the automotive market.

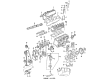

Dodge Caravan Intake Valve Parts and Q&A

- Q: How to Service and Repair Exhaust Valve and Intake Valves on Dodge Caravan?A:Before servicing the valve, remove the cylinder head and, using a universal valve spring compressor, first compress the valve springs. Get rid of the valve retaining locks, valve spring retainers, valve seals and valve springs. Before unscrewing the valves, clear any burrs from the grooves to keep from damaging the guides and check that you know which valve goes where. Clean and check the valves using the required cleaning and inspection procedure. After cleaning the valve stems, apply some clean engine oil and put them into each cylinder on the head. Place new Valve Stem Seals on all the valves with the help of a valve stem seal tool, so the seals are pushed all the way and straight into position on the valve guides. To prevent thorough wear on the guide, it is necessary to use matching oversize valve seals. Install the springs and retainers onto the valve, making sure to only compress the springs slightly so you can install the locks and that the springs are correctly compressed as any misalignment could injure the valve stems. When compressing the valve spring retainers with the tool, make sure neither of the locks has slipped out, as this may happen, so check both of them once the tool is removed. Check after refacing the valve and seat by measuring the installed height B of the valve spring, from the spring seat top to the bottom of the spring retainer. Should the spring measure more than 38.75 mm (1.525 inch height), add a 0.762 mm (0.030 inch) spacer beneath it to meet the correct height.