JeepParts

My Garage

My Account

Cart

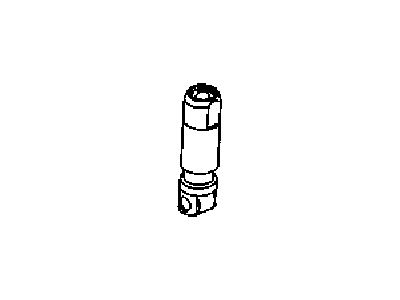

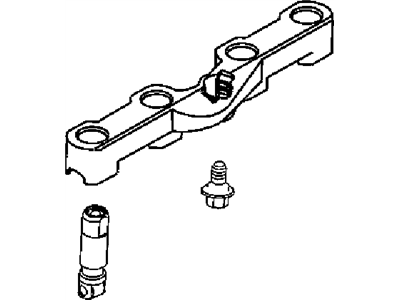

OEM Dodge Challenger Lash Adjuster

Lash Adjuster Lifter- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Lash Adjusters found

Dodge Challenger Valve Lifters Part Number: 5038787AD

$81.47 MSRP: $109.00You Save: $27.53 (26%)

Dodge Challenger Valve Lifters Part Number: 5038784AD

$152.73 MSRP: $229.00You Save: $76.27 (34%)

Dodge Challenger Valve Lifters Part Number: 5038785AD

$236.80 MSRP: $350.00You Save: $113.20 (33%)

Dodge Challenger Valve Lifters Part Number: 5038786AD

$262.30 MSRP: $350.00You Save: $87.70 (26%)

Dodge Challenger Valve Lifters Part Number: 5184332AA

$12.76 MSRP: $18.40You Save: $5.64 (31%)Dodge Challenger Valve Lifters Part Number: 5038788AD

$178.50 MSRP: $238.00You Save: $59.50 (25%)

Dodge Challenger Lash Adjuster

Choose OEM Lash Adjuster that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Lash Adjuster follows strict manufacturing steps to lock in quality and fit. If your Dodge Challenger matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Challenger parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

Dodge Challenger Lash Adjuster Parts and Q&A

- Q: How to Install a Lash Adjuster on Dodge Challenger?A:You should start by lubricating the guide holder for the lash adjuster and the lash adjusters themselves. If you keep the lash adjusters and guide holder assembly, they should be mounted in their right places to prevent harm to the engine. After that, fit the lash adjuster guide holder and lash adjusters, ensuring the lash adjuster retainer bolt ends up at a tightness of 12 Nm (106 in. lbs.). Following this, put in the cylinder head and attach the minus (-) battery terminal. Don't operate the engine above a fast idle until the lash adjusters have settled and become quiet, to avoid damage to the valves. Afterward, turn on the engine, confirm there are no leaks and drive the car around to finish the test.

- Q: How to Manually Bleed Aerated Oil from a Lash Adjuster to Remove Sponginess on Dodge Challenger?A:To do it manually, let your engine run hot, remove the cylinder head cover(s) and carefully bleed out any sponginess using the lash adjuster. Place the Rocker Arm on the base circle of the cam shaft and spin the engine as needed. For checking rocker arm positions, set the gauge pin on Special Tool 8351 to extend out about 20 mm and insert the probe into the service hole. Should the probe tip detach inside the lash adjuster, you must change the rocker arm. Hold the internal check ball in place as you press the rocker arm into the valve to let the lash adjuster collapse fully and hold its position for a second. Lightly let go of the rocker arm which will allow the lash adjuster to move up and fill the high-pressure chamber with oil that doesn't have air. When that's finished, lift out the probe to permit the check ball to sit. If the sponginess is still there, do the process again and if the problem remains, change the rocker arm. When adjusting the exhaust rocker arm positions, release Special Tool 8351 gauge pin so that it is about 20 mm (0.787 in.) outside the tube, then use two release probes to put gauge pins into the holes of the access arm. With gentle pressure, unseat the internal check balls at the same time and press deeply into the valve tip with the rocker arm to collapse the lash adjuster, keeping it there for about a second. Return the rocker arm to its resting point and push the lash adjuster to go all the way in and charge the high-pressure chamber with non-aerated oil, then remove the probes for the check balls to settle. Feel if it's still spongy; in that case, try again and if you cannot remove the sponginess, change the affected rocker arms. Once all the parts are fastened, put in the cylinder head cover(s).