JeepParts

My Garage

My Account

Cart

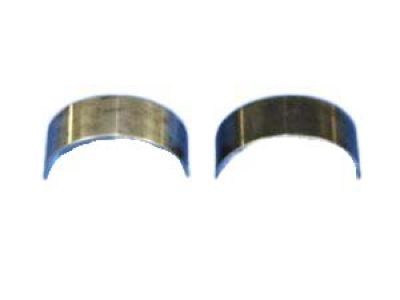

OEM Dodge Journey Rod Bearing

Engine Connecting Rod Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Rod Bearings found

Dodge Journey Bearings Part Number: 4884911AB

$4.79 MSRP: $7.20You Save: $2.41 (34%)Ships in 1-2 Business Days

Dodge Journey Connecting Rod Bearing Part Number: 5184111AF

$3.76 MSRP: $5.65You Save: $1.89 (34%)Ships in 1-2 Business Days

Dodge Journey Connecting Rod Bearing Part Number: 68002286AC

$18.22 MSRP: $27.05You Save: $8.83 (33%)Ships in 1-3 Business Days

Dodge Journey Bearings Part Number: 4884912AB

$16.02 MSRP: $23.55You Save: $7.53 (32%)Ships in 1-2 Business Days

Dodge Journey Connecting Rod Bearing Part Number: 5184113AF

$3.83 MSRP: $5.65You Save: $1.82 (33%)Ships in 1-2 Business Days

Dodge Journey Bearings Part Number: 4884913AB

$2.34 MSRP: $3.55You Save: $1.21 (35%)Ships in 1-2 Business Days

Dodge Journey Connecting Rod Bearing Part Number: 5184112AF

$16.30 MSRP: $23.55You Save: $7.25 (31%)

Dodge Journey Rod Bearing

Choose OEM Rod Bearing that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Rod Bearing follows strict manufacturing steps to lock in quality and fit. If your Dodge Journey matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Journey parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

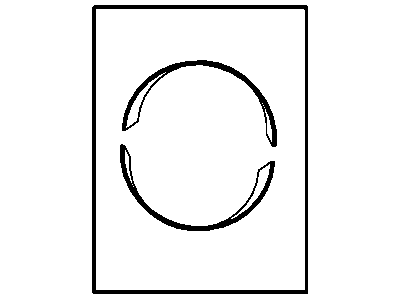

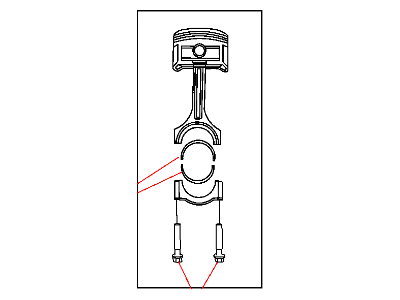

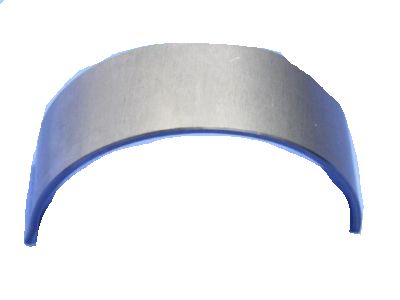

Dodge Journey Rod Bearing is an important part that has a direct impact on the liveliness of the Dodge Journey brand. An important component supporting the crankshaft and camshaft, the Rod Bearing helps rotate by keeping a thin layer of oil under pressure on it, which is a necessity for efficient working of any engine. The Dodge Journey Rod Bearing comes in different forms such as the bi-metal, tri-metal constructions and it has the optimal fatigue strength as well as lubrication system for the high performance racing. This characteristic is especially relevant for the Dodge Journey which is the model valued for its practicality and security; it optimizes the general working performance as well as durability of the engine. Applicable for various Journey models, the Rod Bearing is a crucial component that contributes to preserving the car brand's reliability, which is why it is valued by those drivers who look for a reliable crossover. Regarding the safety of this car, Dodge Journey has had the impressive braking system which together with the Rod Bearing makes driving safe and secure. Also, the Dodge Journey Rod Bearing could have other improved amenities; such things as proprietary dry film coatings and engine eccentricity characteristics to complete the auto power train. The Dodge Journey was discontinued in 2020; however, its features of comfortable, safe, and fairly priced vehicles could still be useful it is crucial to mention the significance of the Rod Bearing for vehicles.

Dodge Journey Rod Bearing Parts and Q&A

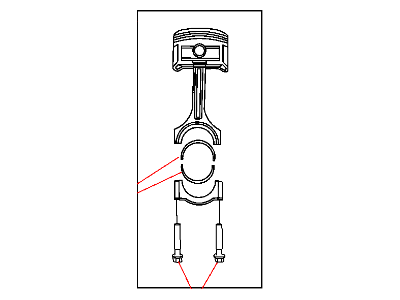

- Q: How Can Rod Bearing Caps Be Marked and Installed for Accurate Assembly on Dodge Journey?A:When removing the bearing caps, make sure to mark them so the right caps are matched up later, as they can't be interchanged. The bearing shell should be installed so the butt of the tang is in the machined groove on the rod or cap, with the cap tangs all on the same side. Rods on the same bank will be finished as a single unit and the taper or out-of-round on all Crankshaft journal surfaces should satisfy the limits given in the specification. Customers can find bearings in 0.007 mm oversize, standard, 0.007 mm undersize, 0.025 mm undersize and 0.254 mm undersize. Bearings should always be fitted together as a set and you cannot use old bearings with new ones. It is not allowed to file or grind the rod-where or bearing end caps. Watchmakers should measure main bearing clearance and connecting rod bearing clearance with Plastigauge. Using the select-fit principle, the clearance in these bearings is controlled by making the crankshaft journals the same size as the requested bearing. The required rod bearing class for each rod is determined by the code 'B' 'A' 'B' 'B' 'B' 'C' found on the #9 counterweight. This means rod #1 is Class 2, rod #2 is Class 1, rod #3 is Class 2, rod #4 is Class 2, rod #5 is Class 2 and rod #6 is Class 3. Rod bearing bolts intended for reuse should be assessed for necking; those showing necking should be replaced. To check a threaded rod, lay a ruler against it: if all the threads don't touch the ruler, you have to change the bolt. Clean the threaded holes and check for any obstructions before start, then do your bolts up once by hand and take turns torquing them, just not too much, to join the parts properly. In the end, tighten all of the connecting rod cap bolts to the correct required torque. Put a dial indicator in place on the engine where it won't move, position the probe against the connecting rod cap being measured. Move the rod to where it barely reaches in back, set the dial indicator to zero and measure where the rod comes to an end. Refer to the engine specifications and make the measurement on all connecting rods, repeating the process each time you turn the crankshaft.