JeepParts

My Garage

My Account

Cart

OEM Dodge Ram 2500 A/C Clutch

Air Conditioning Clutch- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

10 A/C Clutches found

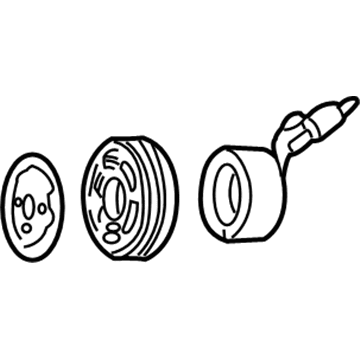

Dodge Ram 2500 Clutch Coil Part Number: 5003681AA

$186.95 MSRP: $279.00You Save: $92.05 (33%)Ships in 1-2 Business DaysDodge Ram 2500 Coil - A/C Clutch Part Number: 5140461AB

$122.73 MSRP: $257.00You Save: $134.27 (53%)Ships in 1-2 Business DaysDodge Ram 2500 Clutch Coil Part Number: 5016127AB

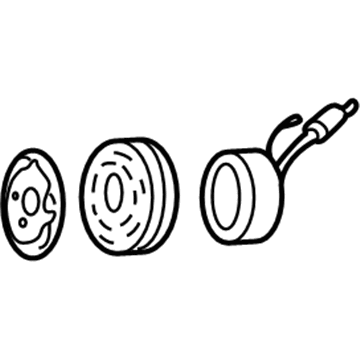

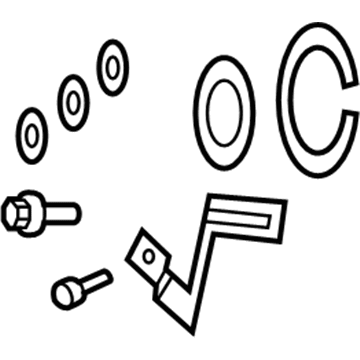

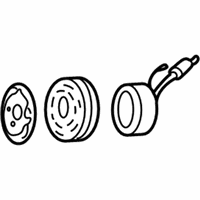

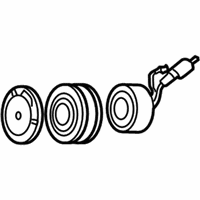

$256.18 MSRP: $377.00You Save: $120.82 (33%)Ships in 1-2 Business DaysDodge Ram 2500 Clutch Kit Part Number: 68032119AA

$41.78 MSRP: $61.40You Save: $19.62 (32%)Ships in 1-2 Business DaysDodge Ram 2500 Clutch Part Number: 5183899AA

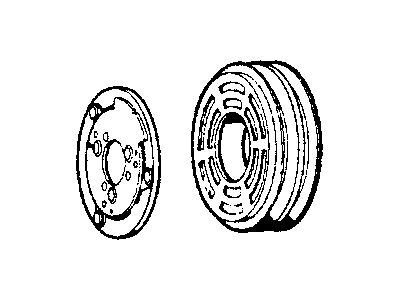

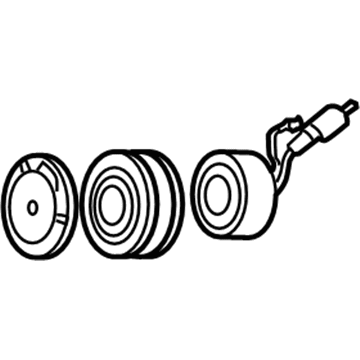

Dodge Ram 2500 Clutch & Pulley Part Number: 5072658AA

Dodge Ram 2500 Clutch Coil Part Number: 4882009

Dodge Ram 2500 Clutch & Pulley Part Number: 4882008

Dodge Ram 2500 Clutch Coil Part Number: 4746789

Dodge Ram 2500 Clutch & Pulley Part Number: 4746786

Dodge Ram 2500 A/C Clutch

Choose OEM A/C Clutch that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each A/C Clutch follows strict manufacturing steps to lock in quality and fit. If your Dodge Ram 2500 matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Ram 2500 parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

The Dodge Ram 2500 A/C Clutch is a major part that emphasizes durability and power of the Dodge Ram 2500 series. This A/C Clutch is designed to activate the A/C compressor, so that there will be proper cooling when the A/C system is turned on. Due to the high durability, the Dodge Ram 2500 A/C Clutch improves the working capacity of the car's air conditioning systems and make automobile travel delightful. Being universal for Ram 2500 enables installation of this A/C Clutch in all configurations of the model and stick to the high level of quality provided by Dodge. However, the importance of A/C Clutch goes beyond just an extra measure towards comfort and convenience of the vehicle owners, it also has a major function and that is related to fuel efficiency as well as safety point of view, as it aids in avoiding pressure on the overtworking of the engine of the car while it is in operation. Outstanding characteristics of the Dodge Ram 2500 A/C Clutch include its solid build and good calibration that eliminates shortcomings that are common with most vehicles such as compromised air conditioning and amplified fuel consumption. This improves on the performance of the vehicle and the longevity of the A/C system as a whole has been boosted by the Dodge Ram 2500 A/C Clutch. The Dodge Ram 2500 A/C Clutch is well known for building reliable and efficient products that are basic to the automotive market; therefore acquiring a Dodge Ram 2500 A/C Clutch is closely suitable in case you are a Ram 2500 owner who would love their car or truck to operated properly and has a comfortable inside climate control system.

Dodge Ram 2500 A/C Clutch Parts and Q&A

- Q: How to Replace an A/C Clutch on Dodge Ram 2500?A:Removing the A/C compressor clutch begins with disconnecting the battery negative cable, uncovering the serpentine Drive Belt and unplugging the compressor clutch coil wire harness connector. After that, lower the bolts securing the compressor to its bracket, slide out the compressor and support it in your engine compartment. Put a spanner wrench (Special Tool C-4489 or its equivalent) on the clutch plate to hold it in place and as you do this, remove the hexnut that connects the plates. Place snap ring pliers on the snap ring to unfasten it and then press the lip of the rotor puller (Special Tool C-6141-1 or its equivalent) into the groove of the removed ring. Place a shaft protector (Special Tool C-6141-2 or its equivalent) at the other end of the rotor. Secure the puller with bolts, C-6461 or comparable and turn the center bolt clockwise in the center until you can free the rotor, while making sure not to touch the end of the compressor. Removed the screw and retainer from the clutch coil lead wire harness, slide the snap ring off the compressor hub, then lift off the clutch field coil. Check the clutch rotor and plate for signs of wear and return them for replacement if there are many scratches. Check for oil in the shaft area; if the cover felt is moist, the shaft seal is gone and the compressor must be changed. See if the rotor bearing is rough or is dripping too much grease; if that's the case, replace both the rotor and clutch plate. Begin installation by setting the clutch field coil and snap ring in place and then attach the clutch coil lead wire harness using the 2.2 Nm (20 in. lbs.) tightened screw. Attach the rotor assembly to the hub of the front compressor with the hollow to the outside and fit it into the bearing with Special Tool C-6871. Make sure the bevel of the front housing snap ring faces outside and fully push it in place, so the clutch won't fail. Install the original shims on the compressor shaft, then put the clutch plate on and tighten the shaft hex nut to 15 - 20 Nm (11 - 15 ft. lbs.). In addition, use a feeler gauge to see if the clutch air gap is between 0.41 and 0.79 millimeters (0.016 and 0.031 inches) and add or subtract shims as necessary.

- Q: How to Burnish a New A/C Clutch on Dodge Ram 2500?A:Once you have installed the new compressor clutch, turn it ON for five seconds, then OFF for five seconds twenty times. Here, switch to the Recirculation Mode on the A/C Heater control, move the blower motor to the highest position and attempt to keep the rpm of the engine around 1500-2000. Seating the opposing friction surfaces during this procedure increases the compressor clutch's ability to produce torque.