JeepParts

My Garage

My Account

Cart

OEM Dodge Ram 3500 Fuel Filter

Gas Filter- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

12 Fuel Filters found

Dodge Ram 3500 Fuel Filter Part Number: 68065608AB

$82.73 MSRP: $125.00You Save: $42.27 (34%)Ships in 1-2 Business Days

Dodge Ram 3500 Fuel Filter Part Number: 4883963AC

$94.22 MSRP: $145.00You Save: $50.78 (36%)Ships in 1-2 Business Days

Dodge Ram 3500 Fuel Filter Part Number: 4874274AC

$59.99 MSRP: $90.00You Save: $30.01 (34%)Ships in 1-2 Business Days

Dodge Ram 3500 Fuel Filter, Lower Part Number: 4897498AA

$51.93 MSRP: $76.15You Save: $24.22 (32%)Ships in 1-2 Business Days

Dodge Ram 3500 Fuel Filter Part Number: 5015581AB

$17.17 MSRP: $24.75You Save: $7.58 (31%)

Dodge Ram 3500 Fuel Filter Part Number: 68001914AB

$53.04 MSRP: $78.70You Save: $25.66 (33%)Ships in 1-2 Business Days

Dodge Ram 3500 Fuel Filter Part Number: 68061634AA

$68.43 MSRP: $102.00You Save: $33.57 (33%)Ships in 1-2 Business DaysDodge Ram 3500 Fuel Filter Part Number: 4864849AB

$96.65 MSRP: $124.00You Save: $27.35 (23%)Ships in 1-2 Business Days

Dodge Ram 3500 Fuel Filter Part Number: 5183410AA

Dodge Ram 3500 Filter, Upper Part Number: 52021983AB

Dodge Ram 3500 Fuel Filter, Upper Part Number: 4798825AD

Dodge Ram 3500 Fuel Filter Part Number: 4864307

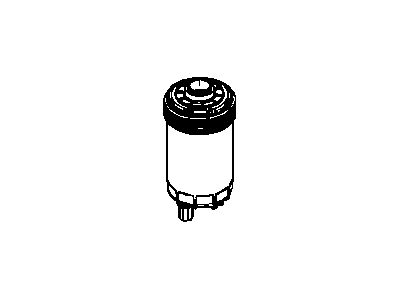

Dodge Ram 3500 Fuel Filter

Choose OEM Fuel Filter that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Fuel Filter follows strict manufacturing steps to lock in quality and fit. If your Dodge Ram 3500 matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Ram 3500 parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

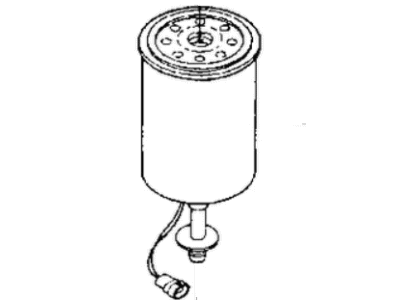

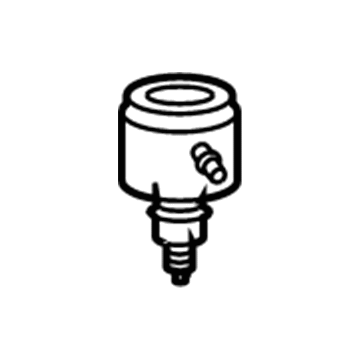

The Fuel Filter is an essential part of Dodge Ram 3500 vehicles as it helps to protect the engine from clogging with dirt, debris and rust coming from the fuel line. This component usually incorporates cartridges that are made from pleated filtering paper to filter out bearer of contaminants to enable clean fuel to reach the engine. This is especially necessary for DT/Nav customer trucks such as Dodge Ram 3500 so as to avoid normal wear and possible failure of fuel machinery. In the different models of Dodge Ram 3500, years of usage have seen fuel filters being implemented in different designs such as bowl type diesel fuel filters that collect water to be drained out in order to protect the fuel system. Such filters may also contain additional elements such as water sensors and fuel heaters in order to provide improved operation in the cold. Knowing and practicing the Dodge Ram 3500 Fuel Filter maintenance program is very crucial in getting the most out of the automotive vehicle in terms of performance and its durability.

Dodge Ram 3500 Fuel Filter Parts and Q&A

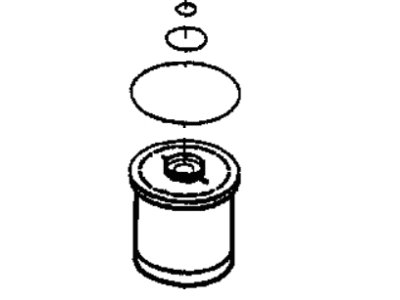

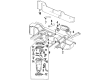

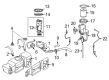

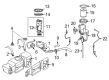

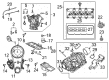

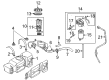

- Q: How to Maintain and Fix a Fuel Filter on Dodge Ram 3500?A:To clean and repair the fuel filter, drain water using the drain valve (9) to remove some water first and all water for filter, drain valve, heater element or Wif sensor replacement. Set a drain pan under the drain hose (7) on the drain valve at the bottom. When the engine is off, turn the drain handle counter-clockwise to Open, leaving it open until no more water and contaminants are draining from the engine. When replacing the drain valve, fuel heater element or Water-In-Fuel (Wif) sensor, first drain the housing totally and dispose of the mixture following the rules. Following draining, turn the valve handle clockwise to get it into the Close position. Before putting in a new filter, clean anything around the housing, open the canister lid with a socket on the large hex bolt (2) and remove the O-ring. Turn the filter vertically to take it out of the gun. Disconnect the electric connector, wipe away any debris, slide out the Wif sensor from the socket as you rotate it counter-clockwise and check the O-ring for any signs of damage. To change the fuel heater element, take out the fuel filter, unplug the electrical connector and remove the two screws (3) with a T-15 Torx head. Let's first disconnect the drain hose, remove the four T-15 Torx head screws from the mounting plate and then remove the drain valve. While you plug in a new filter element, remember to clean the filter compartment and everything attached to it, fit an O-ring around the canister's lid, oil it up, add the new element into the canister and secure the lid to 34 Nm (25 ft. lbs.) of tightness. To install a Wif sensor, put in a new seal, lubricate it, install the sensor, tighten it to 2.5 Nm (25 in. lbs.) and attach the electrical connector. For the fuel heater element, put it and the Thermostat into the housing, make sure the screws are tightened to 1-1.5 Nm (13 in. lbs.), attach the electrical wiring cover and add and lubricate a new O-ring on the filter housing cover before tightening it. Afterwards, fit two new O-rings onto the drain valve, smear silicon grease onto both materials, connect the valve, tighten all screws to 1-1.5 Nm (8-13 in. lbs.), connect the drain hose and start the engine to see if there are any leaks.