JeepParts

My Garage

My Account

Cart

OEM Dodge Ram 3500 Van Wheel Hub

Wheel Axle Hub- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Wheel Hubs found

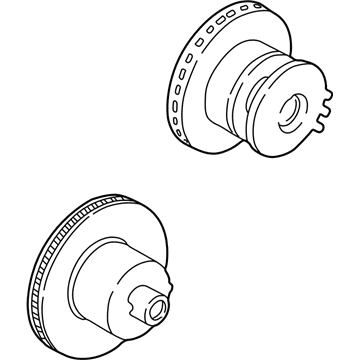

Dodge Ram 3500 Van Hub & Rotor, Front Part Number: 52009414AB

$81.94 MSRP: $103.87You Save: $21.93 (22%)Ships in 1-2 Business DaysDodge Ram 3500 Van Hub & Rotor, Front Part Number: 52009414

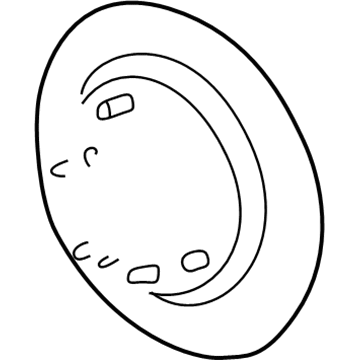

$87.25 MSRP: $110.61You Save: $23.36 (22%)Ships in 1-2 Business DaysDodge Ram 3500 Van Hub Assembly, Rear Part Number: 52009523

Dodge Ram 3500 Van Hub Assembly, Rear Part Number: 52009517

Dodge Ram 3500 Van Hub & Rotor, Front Part Number: 52009415AC

Dodge Ram 3500 Van Hub Assembly, Rear Part Number: 52008594

Dodge Ram 3500 Van Wheel Hub

Choose OEM Wheel Hub that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Wheel Hub follows strict manufacturing steps to lock in quality and fit. If your Dodge Ram 3500 Van matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Ram 3500 Van parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

Dodge Ram 3500 Van Wheel Hub Parts and Q&A

- Q: How to service and repair the wheel hub and axle bearing for the 248 RBI Axle on Dodge Ram 3500 Van?A:You should remove the wheel and tire, then the drum and axle shaft, to work on the wheel hub and axle bearing of the 248 RBI Axle. Following this, use Socket DD-1241JD to get the lock wedge and adjustment nut out, plus next, take the hub assembly out to slide the outer axle bearing out. Trash the inner grease seal and continue by installing Installer 5064 and Handle C-4171 to remove the grease seal and inner axle bearing from the hub. Remove the bearing cups near the hub bore by using either a brass drift or a verified removal tool. Wipe the axle bearings clean, then clean the inside of the hub with a suitable solvent before you put on the bearing cups with Installer 8151 and Handle C-4171. Lubricate the bearing cup on the wheel and put the inner axle bearing into the hub. Apply a fresh bearing grease seal using Installer 8149 and Handle C-4171, look for any roughness on the bearing and seal surface of the axle spindle, remove it if found and put a thin film of multi-purpose NLGI, grade 2, EP-type lubricant on the axle. Pay attention so the bearing grease seal does not touch the spindle threads on the axle tube when you install the unit. Firmly place the hub onto the axle, put the outer axle bearing in place and screw the hub bearing adjustment nut with Socket DD-1241D. As you rotate the wheel, crank the adjustment nut to a pressure of 163-190 Nm (120-140 ft. lbs.) Then drop the nut by 1/8 of a turn to achieve 0.001 to 0.010 inch wheel bearing end play. Align the locking wedge with the spindle and nut and make sure it's in a new spot. Now, place the axle shaft, brake drum and wheel and tire in position.